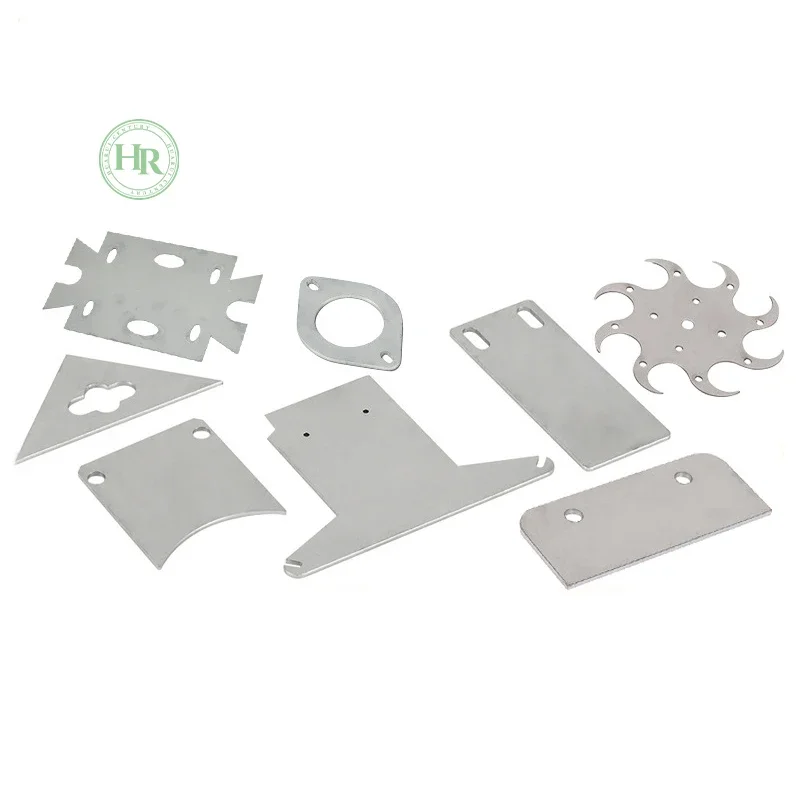

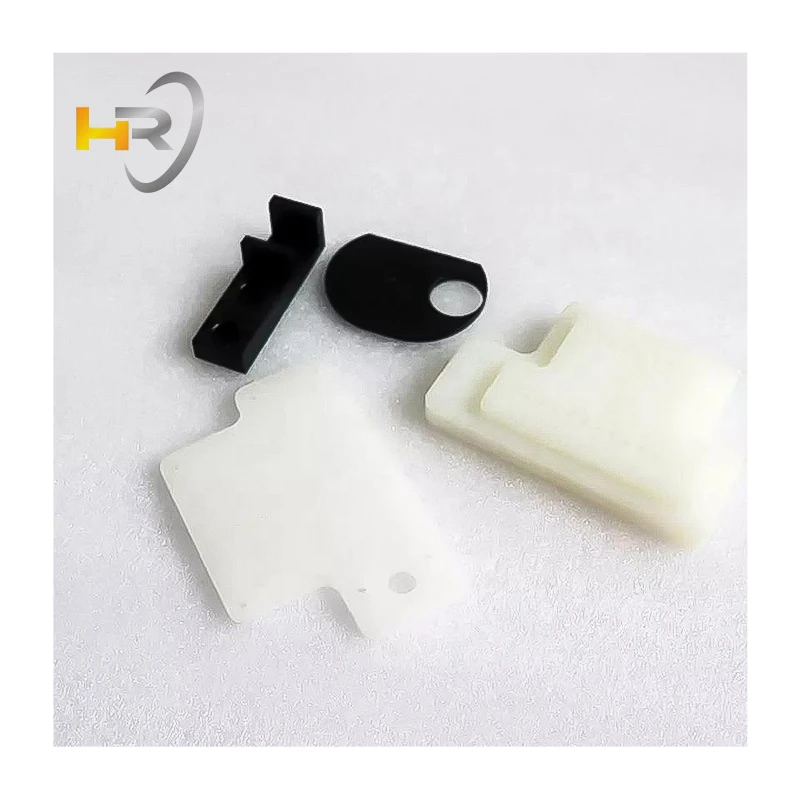

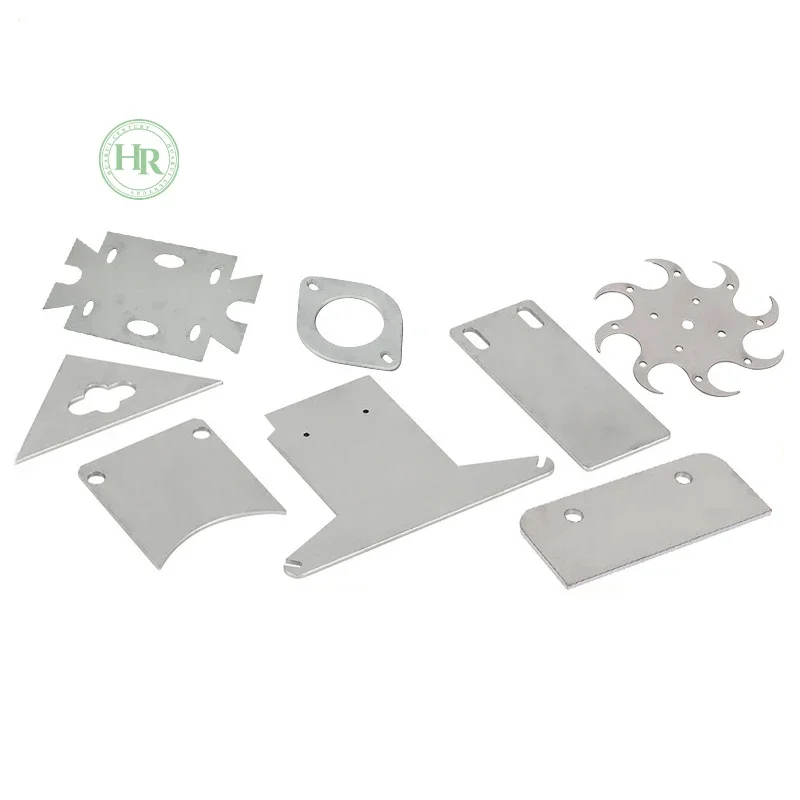

Custom aluminum stainless steel sheet metal fabrication laser cutting parts service

| Farayn | Faahfaahinta |

|---|---|

| Gaalka Xarunta | Guangdong, Ciina |

| Magaca Caruurta | HR |

| Nooca Alaabta | Qatada Laser / Qatada / Qatada Astaamo |

| Qalabka | Fulxad Rust-ila / Aliminiyam / Fulxad Dhelo / Fulxad La Cayimay |

| Hela iyo Gaadh | La iskudhafan Hore Edeynta |

| Ogaan | Sida loo baahan yahay |

| Daaweynta Dusha | Iyada la doonayo |

| Shahaadada | ISO9001 |

| Baakadaha | La habeeyey |

Magaca |

xogga ugu muuqaal ah sheet metal fabrication parts service |

Qalabka |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc ee kale |

Daaweynta Dusha |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Ogaan |

+/-0.01mm, 100% QC carruurka caafimaadka before delivery, waxaad ku sameyn doontaa carruurka caafimaadka form |

Dugsiyada Xanuun |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Habaynta |

Stamping ,Sheet metal fabrication |

Fayl Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Faa'iidooyinkayaga |

1.) 24 saacadda sheegiska & Qaadka Dhexeeynta/Qaadka. 2.) 100% QC xaqiijinta qaabka ah kuwa soo galo, oo ka mid ah waxaa lagu heli karaa dacweynka xaqiijinta.

3.) Ku sameyn kartaa sharciyada uun, sharci iyo lacagta ah service, taajilada iyo shaqsihii, eecc. |

Muuqaalka guud ee alaabta

Shenzhen Huarui Century Technology Co., Ltd. siinayaa qaybta buuxda custom aluminum stainless steel sheet metal fabrication laser cutting parts service la xidhiidhaaya sifooyinka sayniska iyo shaqsi-guddoomsi. Wixii la isticmaalo CNC laser cutting technology, aannu sameyno qaybooyin saafiyadda isku yaabka sare leh, kala duwidda sare, iyo saxda habka badan. Khidmatuna ku taasisaa samaysida qalabka maankul ah ee elektronikada, mashinkii, motarada, haweenka gargaarka, dabaylaha, enclosures, iyo mid kale.

Aannu heli karno in aan kala shaqeeyo tiro weyn oo noocyo, iyaga jira fulaysdarrka, aluminomka, fulaysdarrka fulays, koppar, iyo warqadaha lacag la'ee. Ilmasha horumarsiga mudahara ilaa ugaasinta bulshada, timheedkaygana wuxuu xaqiijinayaa ugaasinta dhammeedka, waqtiga yarrahsan, iyo shaqada raacaysan markasta oo ay soo maranayo.

Xiriirkooda ah waxaa lagu sameyn doonaa:

-

Kalluunka laser sax ah, tolerances dhiman, iyo awood sare leh.

-

Ugaasinta lix saaraha si loo hortago waqti-dhawaanta.

-

Midhoog la'aa siyaabaha complex, slots xooggan, iyo furitaanka lagu maamula.

-

Isku darka CAD/CAM si loo hela isbedel buuxda ka dib ugu dhow digital files ilaa alaabta dhameystiran.

-

Awoodda weyn ee ku qabsatada, dhisidida iyo ku dhisidida saararka ilaa saararka buuxa ee shuulka.

Waxaan kula taageerna sharciweyn / ODM, tijaabo gaaban, iyo dhammaan u fudud, kaas aawadeed aan noqon karino sharaf kale ah ee dhisidka saararka shuulka iyo hawlaha sadaaqadda dheer-sammaan.

Faa'iidooyinka alaabta

Qoto dheer-dheer iyo saxda gaarka ah

Salkiinku custom aluminum stainless steel sheet metal fabrication laser cutting parts service wuxuu isticmaalaa xadgudubka laaser ee jiidha awoodga leh oo ku guulaysan ±0.1 mm qoto . Mugga saxda waxa uu siimay isku filinta khat daris, khalad-dheerro lagu yaabba, iyo awood mid ah oo dhan gudahooda. Hadii kaloo mar walba la qado, nidaamkuna wuxuu sii socda in ay tahay mugga laaserka, si loo dhaqmo kala duwidda mugga, iyo si loo hubiyo isku dhasha badan oo raad-faad leh.

Caynada edge-ka fiican iyo soo horjeedka yar

Qadhidka laaser waxa ku abuura xariiryo habboon, caano oo leh qurxinta yar anaa ah, kaas oo si wanaagsan uga saara in lagama filnaayo ama dhammeeyo saasigu. Gaaban dhexdaba iyo jiritaanka daryeelka ee daryeelka ah ay ka dhimanaysaa in ay tixraacaan ama laabta, gaar ahaan qalabka qalabka hoose ilaa dhexe. Tani wuxuu garanaysaa in ay tahayn tixraac aad u fiican oo kala duwan, waxaana heli kara in lagabnaado, lagabnaado, iyo dhammeeyo sare.

Talanta iyo Dukamaynta Qalabka Qalabka Qalabka Qalabka

Qalabka laasarka ee aynu taageerna shaxal, qalabka yar, shaqsiyaal, xagga xooggadeed, iyo xarafadaha fiican , kaas oo saxeexa iyo muwaadinka u siinaya awood u badan. Kala qaybinta waxa laga yaabaa in lagu daryeeyo si loo hortagro iyo lagu daryeeyo khaladka. Sidoo kale, hababka laasarka ay ku badan karaan si degdeg ah loo beddelo sabab la iyo gaaban, kaas oo ku filan kara in lagabnaado, badan, iyo hanti dheer oo kala duwan oo aan la jirin awoodda badan.

Masaakada fudud

Qooshigii maareynta ku saabsan

Qaybaha galgalinta laaser ee shuulka maabna ah waxaa loo isticmaal jiritaanka mašin, qaybood, plateynta saafid, habaabinta mašin, iyo hawsha xadgudub. Qaybuhuna ah ku taal, awood, iyo waqti dheer in ay ku duraan jidadka industriyaariga.

Elektroniksi Guryaanki iyo Xaruur Tixgelinta

Waxaan noqonaysaa qaybood tixgelinta elektroniksi guryaanki, rackada server, qaybood xariirinta xubnaha, iyo qaybood kororinta. Sida ugu fiican ee edge iyo goobta saxda ah ee billigsanaanshaha ay ka dhigantahay in ay lagu diyaaraysta qaybood jiritaan iyo shaandharka yar.

Mašin, Dhaqaal, iyo Hawsha Energiyada Cusub

Khidmatnaydu ku qoran tahay tray bataarey, qaybood EV, qaybood dashboard, plateynta saafid sensor, xaruur ilaaliya, iyo qaybood aluminom qalab. Shaqada sare ay ka caawinaysaa in qalbiga ka yaraado, in ay raacdo turjuman wanaagsan, iyo in ay kalsooni doonto koronaadhka heerarka sarrifka.

Xaruurdadka Makaabi iyo Dhulalka

Falaarka la socotay laso badhac, alamaad, qalloocin la farshaxan, habkabka ilmo, iyo hardwareyada mebeliska ayaa loo saxeeyn karaa badhac fudud iyo natiijo gaar ah. Ilaalinida sare waxa uu siinayaa awoodaha khalka iyo muuqaalka.

Socodka Horumarinta iyo Socodka Gaaban

Si ay uusan ka bilaaban horumarinta produktiga cusub, waxaan helnaa tijaabo noqon buuxda iyo sareen saaran in lagama filna , si aan la qaadin sida xaqiiqda oo laga qaado iyo taasoo taageyso dabeecadihii dib uurtida joogto ah, kaasoo khatartaynaaya korolkii horumarinta iyo qiimaha.

Bilowga Hantiyada Kala Duwan ee Kaalinta

Si aad bilowdo agabtidaaga, rahbahood u sheeg:

-

dibujiyada 2D/3D: PDF / DWG / DXF / STEP / IGES

-

Nooca khalka iyo jiritaanka

-

Waxyaabihii ilaalinida sare (dayrka powder, anodizing, plating, iwm)

-

Tirada agabka iyo muddada soo jeedinta

-

Jagooyinka shaqada ama wanaagsiga khasab ah

Injineerihuna way siinayaan soo hadal daaqder , taageero teknoolojiga, iyo qiimayn khabar in la sameeyo si loogu dhaafmo kororin kacaanka leh. Dhammaantiisana ayaa lagu bartaya in la soo saaro iyo warqaddaha in la soo saaro.

Nala soo xiriir maalinta hadda in aad ku hadasho qaadashada, taajeedka injineerka, ama fursado socdaal OEM.

Sheelka Caruurta (FAQ)

S1: Maxaad noqonaysa lakoobaha?

Waxaannu shaqeeynaa alchini (201/304/316), jajab alchini (5052/6061/6082), fulsid ful, ful dhuxus, kupur, iyo ilmaha ful oo la xidhay.

S2: Maxaa noqon doonaan sida aad u baahantahay ee kaydankii guud?

Waxaannu aqbaliyneyne PDF, DWG, DXF, STEP, IGES, iyo caadiyaad kale ee CAD. Waxaannu hubineynaa in ka beddelo CAD/CAM si sax ugu yaraan.

Q3: Maxay MOQ ka hor inta badan?

Aynu taageernaayo tibixyo iyo tibixyo yar tiba roobka 1 , haddana shakeli karaan weyn oo dhan.

S4: Maxaad isticmaali kartaa hababka saafarka sare?

Waxaan u siiyaannaa saafarka powder, anodizing, brushing, sandblasting, electroplating, laser engraving, iyo kale si ay tahay arrimo iyo xaqiiqda.

S5: Sidee aad buuxi kartaa awoodda alaabta?

Waxaan isticmaalaannaa tijaabo xoog badan, raad-rabaadka hebsan, iyo tijaabo dambe ah ka hor inta aan la dirin. Waxaan heli karnaa taageero buuxda marka la codsado.

S6: Miyaad tijaabi kartaa jeexinta iyo jaro celcelinta ilaa saafarka laaser?

Haa. Waxaan u siiyaannaa adeeg cusub oo guud in lagu jeexiyo, la daryeelo, la teypteelo, la geediyo, iyo la jaro celceliyo mekhatuniksida si loo bixiyo qayboon la isku dayrin karo.