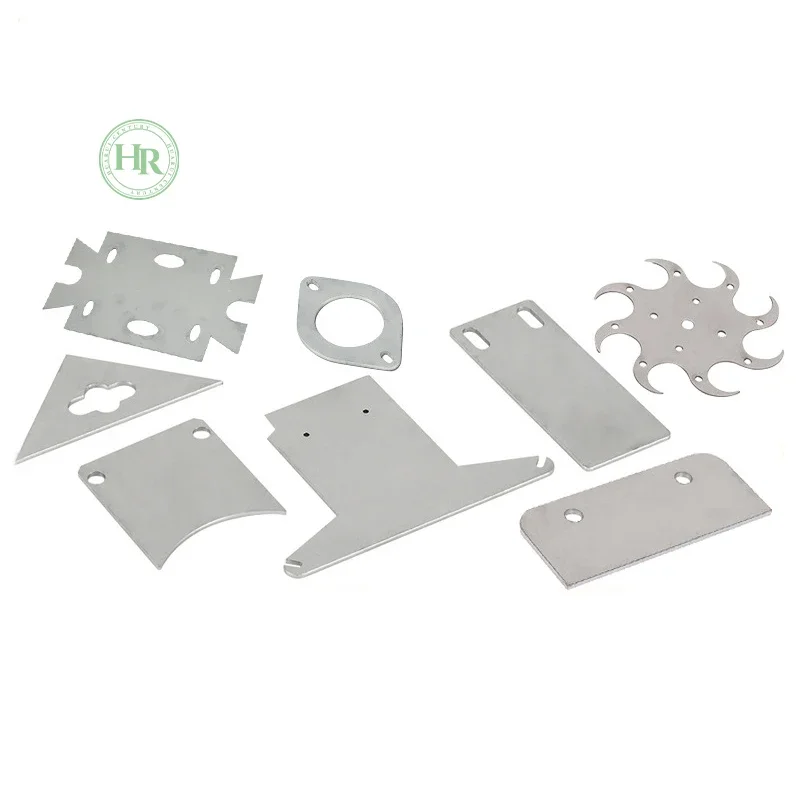

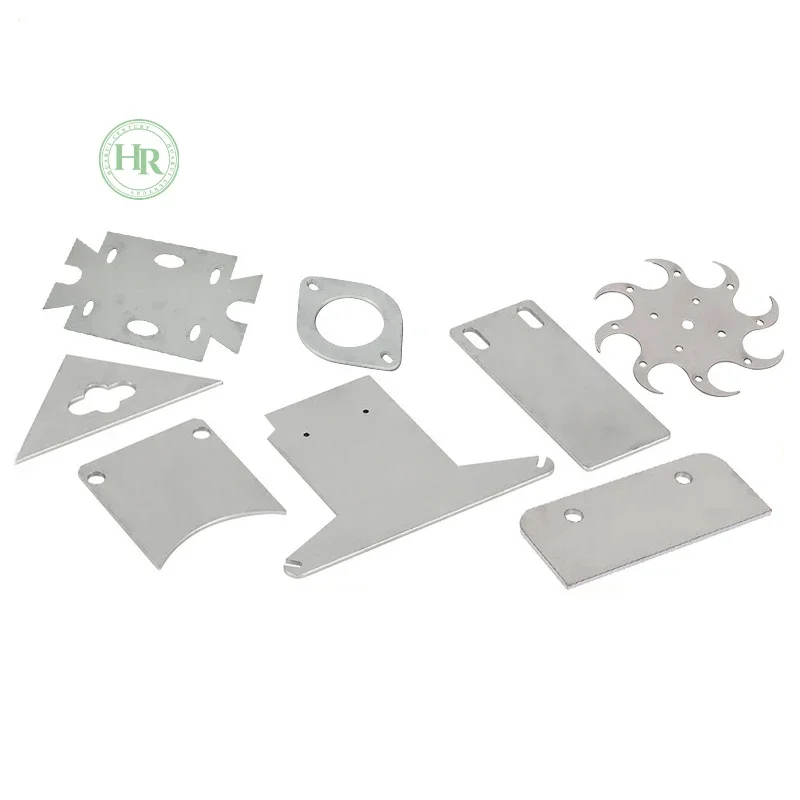

Custom aluminum stainless steel sheet metal fabrication laser cutting parts service

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

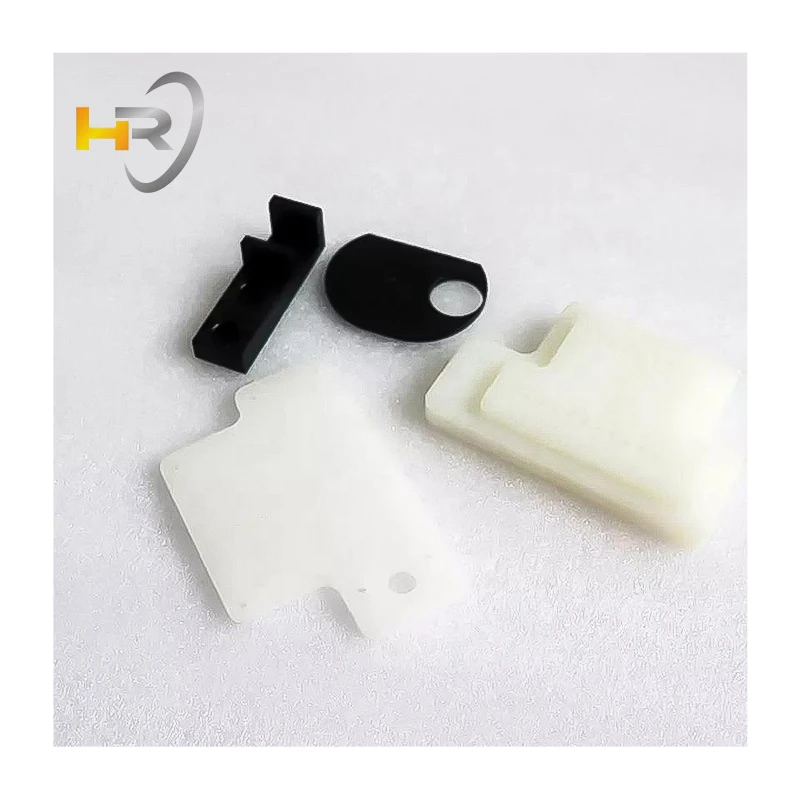

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Name |

custom manufacturing sheet metal fabrication parts service |

Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Processing |

Stamping ,Sheet metal fabrication |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Our Advantages |

1.) 24 hours online service & Quickly Quote/Delivery. 2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) To provide production design, production and technical service, mould development and processing, etc |

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. provides a full range of custom aluminum stainless steel sheet metal fabrication laser cutting parts service tailored for industrial and commercial applications. With advanced CNC laser cutting technology, we manufacture precision sheet metal components with exceptional dimensional accuracy, excellent edge quality, and consistent repeatability. Our service supports custom part production for electronics, machinery, automotive, energy equipment, fixtures, enclosures, and more.

We are capable of working with a wide selection of materials including stainless steel, aluminum, steel alloys, copper, and coated sheet metals. From prototype development to mass production, our team ensures optimal manufacturing efficiency, short lead times, and reliable performance across every order.

Key features include:

-

Precise laser cutting with tight tolerances and stable quality.

-

High-speed production for improved time-to-market.

-

Flexibility for complex geometries, intricate slots, and customized openings.

-

CAD/CAM integration enabling seamless transition from digital files to finished products.

-

Strong capability in bending, forming, and welding for complete sheet metal assemblies.

We support OEM/ODM cooperation, fast sampling, and scalable production, making us an ideal partner for sheet metal product customization and long-term supply programs.

Product Advantages

High Precision Cutting and Dimensional Accuracy

Our custom aluminum stainless steel sheet metal fabrication laser cutting parts service utilizes high-performance fiber laser equipment capable of achieving ±0.1 mm tolerance. This level of accuracy ensures tight-fit assembly, reduced machining defects, and uniform quality throughout the batch. Even in repeated cutting, the system maintains consistent beam positioning, preventing dimensional drift and guaranteeing reliable mass-production consistency.

Excellent Edge Quality and Minimal Post-Processing

Laser cutting creates smooth, clean edges with little to no burrs, significantly reducing the need for grinding or secondary finishing. The narrow kerf width and controlled thermal input minimize warping or deformation, especially for thin-to-medium sheet thicknesses. This ensures a visually clean appearance and enables immediate follow-up operations such as bending, riveting, and surface treatment.

Efficiency and Flexibility for Complex Metal Fabrication

Our laser cutting supports complex shapes, micro slots, mesh structures, sharp angles, and fine contours, allowing engineers and designers greater design freedom. Material nesting can be maximized to enhance utilization and reduce waste costs. Additionally, laser parameters can be quickly re-programmed for different materials and thicknesses, making it highly suitable for multi-variety, fast-turnover custom orders without expensive tooling investments.

Application Scenarios

Industrial Machinery Components

Custom sheet metal laser cutting parts are widely used in machinery housings, brackets, mounting plates, machine guards, and automation equipment. Our components deliver high strength, stable performance, and long-term durability in industrial working environments.

Consumer Electronics and Precision Enclosures

We supply precision-cut parts for electronic device housings, server racks, communication equipment brackets, and cooling components. Enhanced edge finishing and accurate hole positioning ensure compatibility with sensitive assemblies and compact design requirements.

Automotive, Transportation, and New Energy Equipment

Our service covers battery trays, EV structural parts, dashboard elements, sensor mounting plates, protective covers, and lightweight aluminum components. Advanced fabrication supports weight reduction, safety compliance, and corrosion resistance in demanding conditions.

Architectural and Interior Metalworks

Laser-cut decorative panels, signage, ventilation grilles, lighting fixtures, and furniture hardware can be processed with aesthetic detailing and complex artistic patterns. Surface finishing options extend material performance and visual appearance.

Prototyping and Low-Volume Production

For new product development, we offer fast-response sampling and on-demand manufacturing, eliminating mold investment and supporting frequent design updates. Small-batch precision fabrication ensures product validation before mass rollout, reducing development risk and costs.

Start Your Custom Project with Us

To begin your order, simply provide:

-

2D/3D drawings: PDF / DWG / DXF / STEP / IGES

-

Material type and thickness

-

Surface treatment requirements (powder coating, anodizing, plating, etc.)

-

Order quantity and delivery schedule

-

Application environment or special performance needs

Our engineers will provide a rapid quotation, technical support, and manufacturability assessment to ensure your project moves forward efficiently. Global shipping and export documentation are fully supported.

Contact us today to discuss pricing, engineering advice, or OEM partnership opportunities.

Frequently Asked Questions (FAQ)

Q1: What materials do you support?

We work with stainless steel (201/304/316), aluminum alloys (5052/6061/6082), carbon steel, galvanized steel, copper, and coated metal sheets.

Q2: What formats do you require for design files?

We accept PDF, DWG, DXF, STEP, IGES, and other CAD formats. We ensure seamless CAD/CAM conversion for accurate processing.

Q3: What is your minimum order quantity?

We support prototype and small-batch orders starting from 1 piece, as well as large-scale production runs.

Q4: What surface finishing options are available?

We offer powder coating, anodizing, brushing, sandblasting, electroplating, laser engraving, and more for performance and aesthetics.

Q5: How do you guarantee product quality?

We apply strict dimensional inspection, material traceability, and final QC checks before shipment. Full inspection reports can be provided upon request.

Q6: Do you support bending and assembly in addition to laser cutting?

Yes. We offer a complete fabrication service including bending, welding, tapping, riveting, and mechanical assembly to deliver ready-to-install components.