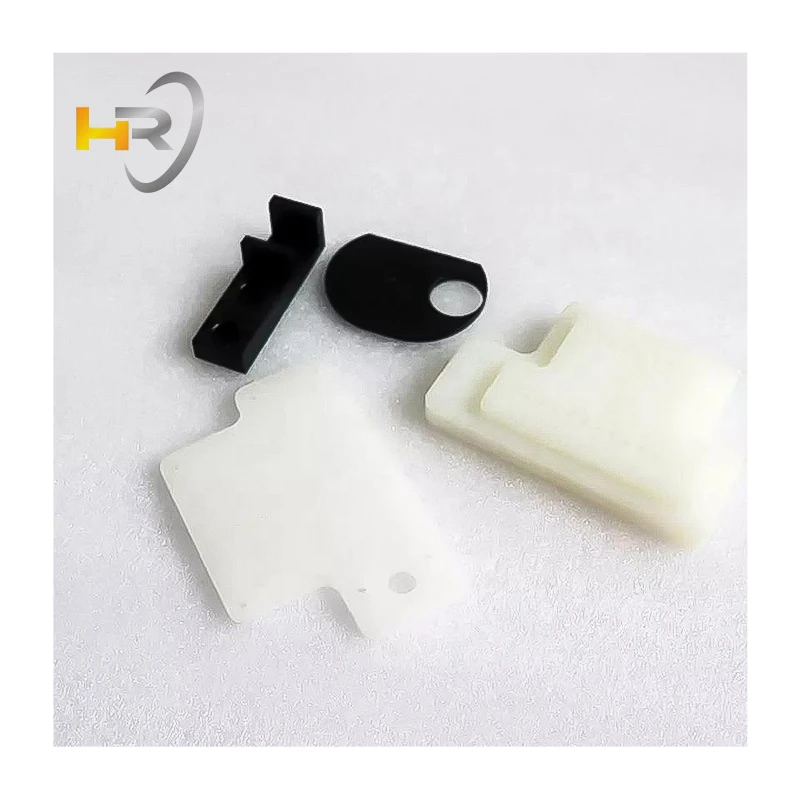

Rapid Nylon Prototype CNC Machining Custom Plastic Parts 3 to 7 Day Sample Service

Accelerate your product development with our dedicated rapid prototyping service, specializing in high-precision CNC milling of nylon and other engineering plastics. We deliver functional, durable prototype parts in as fast as 3 to 7 working days, with no minimum order quantity, starting from just one piece. Our process ensures prototypes meet tight tolerances and possess the material integrity needed for real-world testing, providing a reliable bridge from design to production. Ideal for functional validation, market testing, and pre-production runs across automotive, consumer electronics, and industrial sectors. Experience a streamlined workflow from instant quote to fast delivery with our China-based manufacturing expertise.

Material |

Iron, Zn Alloy, Aluminum Alloy, Stainless steel, Aluminum |

Process precision |

Die casting, lathe, spring, cnc, stamping |

OEM |

Available |

MOQ |

1Pcs |

Mass lead time |

15-20 days |

Sample time |

3-7 days |

Payment terms |

T/T, L/C, Money Gram, PayPal, Crash, Western Union |

Country of origin |

Shenzhen, China |

In the race to innovate, time spent between a digital design and a physical, testable part is time lost. For engineers and product developers, the ability to rapidly iterate and validate designs is not just convenient—it is a critical competitive advantage. Our specialized rapid prototyping CNC service is engineered to compress this timeline dramatically. We focus on delivering custom CNC prototype milling in performance plastics like nylon, providing you with high-fidelity, functional parts within days, not weeks. This service is the essential tool for transforming ideas into tangible assets, reducing development risk, and ensuring your product reaches the market with confidence and speed. By choosing our CNC plastic parts service for your nylon parts, you choose a path of accelerated innovation.

Why Speed in Prototyping Translates to Market Leadership

The traditional barriers to prototyping—high costs, long lead times, and minimum order quantities—have stifled innovation for too long. We redefine this process by making it fast, accessible, and reliable. A 3 to 7 day sample turnaround means you can test a design, learn from it, and implement changes in a single sprint cycle. This agility allows for more design iterations within the same budget, leading to a more refined, robust final product. Faster prototyping directly de-risks your project by uncovering potential design flaws, assembly issues, or material mismatches early, before committing to expensive production tooling. In today's fast-paced market, this speed is not merely a service feature; it is a strategic enabler that can define the success of your product launch.

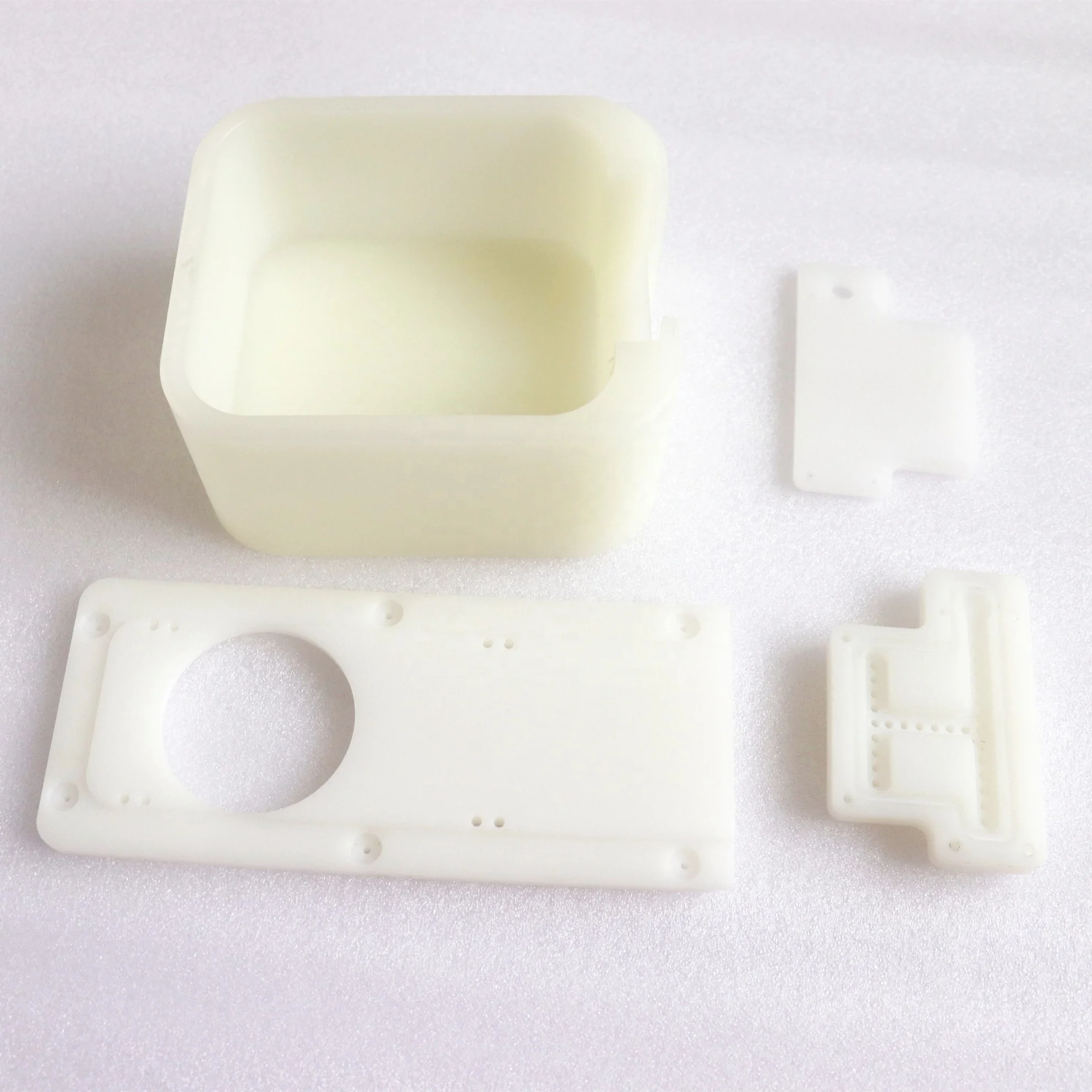

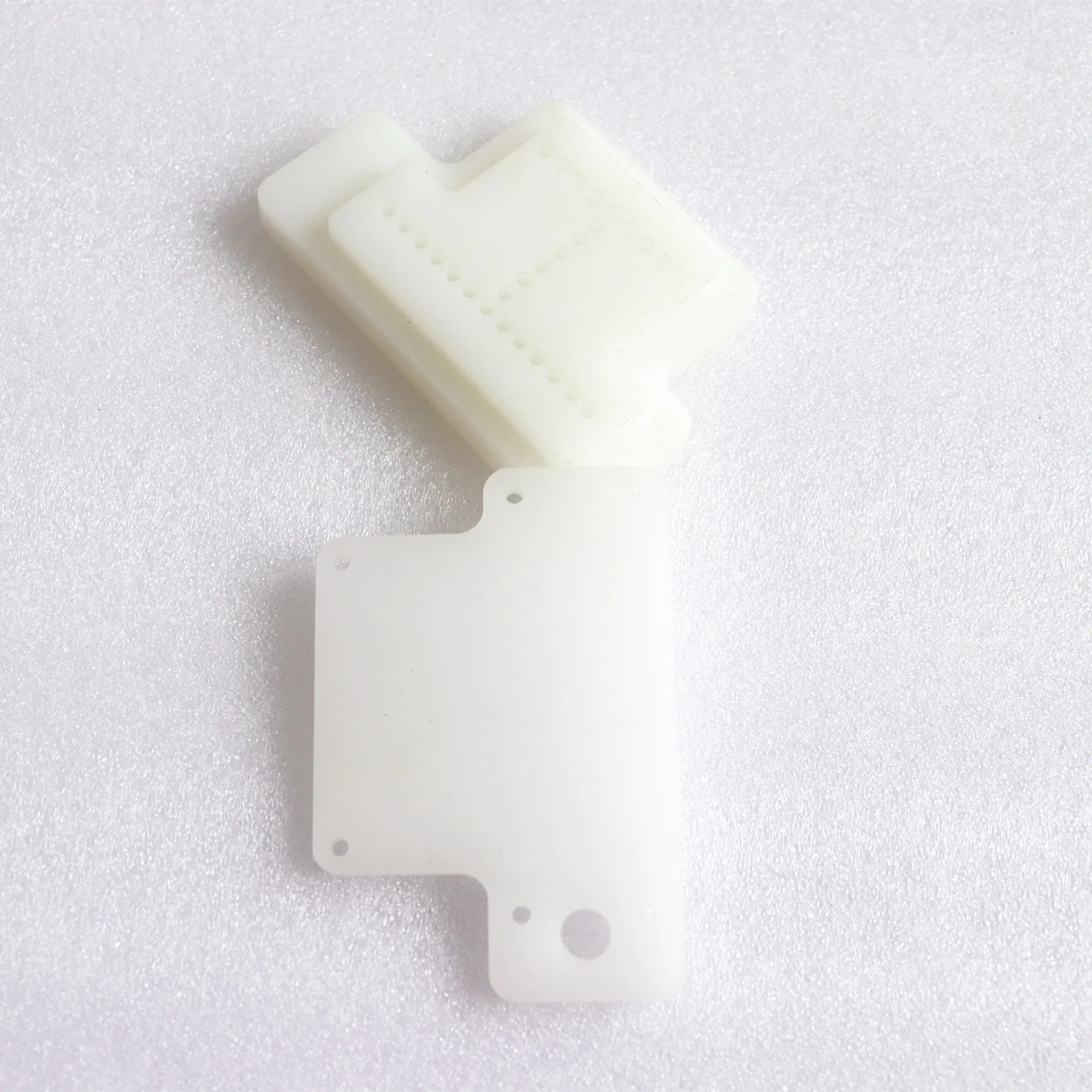

Nylon: The Strategic Choice for Functional, Durable Prototypes

Not all prototypes are created equal. While visual models have their place, functional testing demands a prototype that behaves like the final product. This is where nylon prototype parts excel. Nylon (Polyamide) offers an exceptional balance of strength, toughness, wear resistance, and slight flexibility—properties often required in end-use components. By prototyping in nylon, you gain authentic insights into how your part will perform under stress, fatigue, and environmental exposure. Our expertise in CNC machining nylon parts ensures these material properties are preserved. We employ specific tooling and machining strategies to manage nylon's tendency to absorb moisture and warp, delivering a dimensionally stable prototype that provides reliable performance data and builds confidence in your design long before mass production begins.

A Workflow Engineered for Velocity and Transparency

We understand that a promise of speed is meaningless without a reliable process to deliver it. Our CNC prototype service is built on a streamlined, transparent workflow designed for efficiency at every step. It begins the moment you upload your 3D CAD file to our secure portal. Our engineering team promptly conducts a Design for Manufacturability (DFM) review and provides a clear, fixed-price quotation, often within 24 hours. Upon approval, your project is immediately scheduled on our dedicated rapid prototyping production lines. You receive regular updates, and upon completion, each part undergoes a stringent quality check against your specifications. From inquiry to shipping, our process is optimized to uphold our 3 to 7 day promise, giving you predictability and peace of mind throughout the development phase.

Precision That Prototypes the Future: Beyond Basic Shape

A true functional prototype must do more than merely resemble the final part; it must embody its precision. Our custom CNC prototype milling utilizes advanced multi-axis machining centers capable of achieving the tight tolerances and complex geometries your design demands. This means your plastic CNC parts prototype will feature accurate threads for fasteners, precise press-fit interfaces for bearings, and smooth finishes in critical wear areas. This level of detail allows for comprehensive functional testing, user experience trials, and even use as pre-production samples for sales and marketing purposes. By investing in a high-precision CNC-machined prototype, you are validating not just the concept, but the manufacturability and assembly of the final product, saving invaluable time and resources downstream.

Your Bridge to Production: Seamless Scaling from One to One Thousand

The journey from a single prototype to volume manufacturing is often fraught with challenges, including supplier changes and requalification. We eliminate this friction. As your trusted manufacturer from the very first piece, we ensure a seamless transition. The processes, quality standards, and material knowledge honed during your prototyping phase are directly applied to your pre-production and batch orders. Our mass production lead time of 15-20 days for confirmed designs ensures a smooth and rapid scale-up. This continuity from prototype to production guarantees consistency, reduces administrative overhead, and accelerates your overall time-to-market, solidifying our role as a true end-to-end partner in your product's lifecycle.

Designed for Global Collaboration: Easy Access, Secure Engagement

As a forward-thinking manufacturer based in Shenzhen, China, the heart of global advanced manufacturing, we are built for seamless international collaboration. We accept all major CAD file formats and communicate in clear, technical English. To facilitate easy and secure transactions for our global clientele, we offer a wide range of payment terms, including T/T, L/C, and convenient online methods like PayPal. Our location provides us with unparalleled access to a mature supply chain, which we leverage to source high-grade materials and ensure efficient logistics, further reinforcing our commitment to reliability and speed for customers worldwide.

Initiate Your Next Innovation Sprint Today

Taking the first step towards a faster development cycle is simple. If you have a design that needs to be in your hands for testing next week, we are ready. Share your CAD file and requirements with our team. We will quickly provide a transparent analysis and a competitive quote that reflects the value of speed and precision. With our 1-piece MOQ policy, you can start small, validate big, and scale with confidence. Contact us now to experience how our dedicated rapid prototyping CNC and CNC machining nylon parts service can become the most powerful accelerator in your product development toolkit.