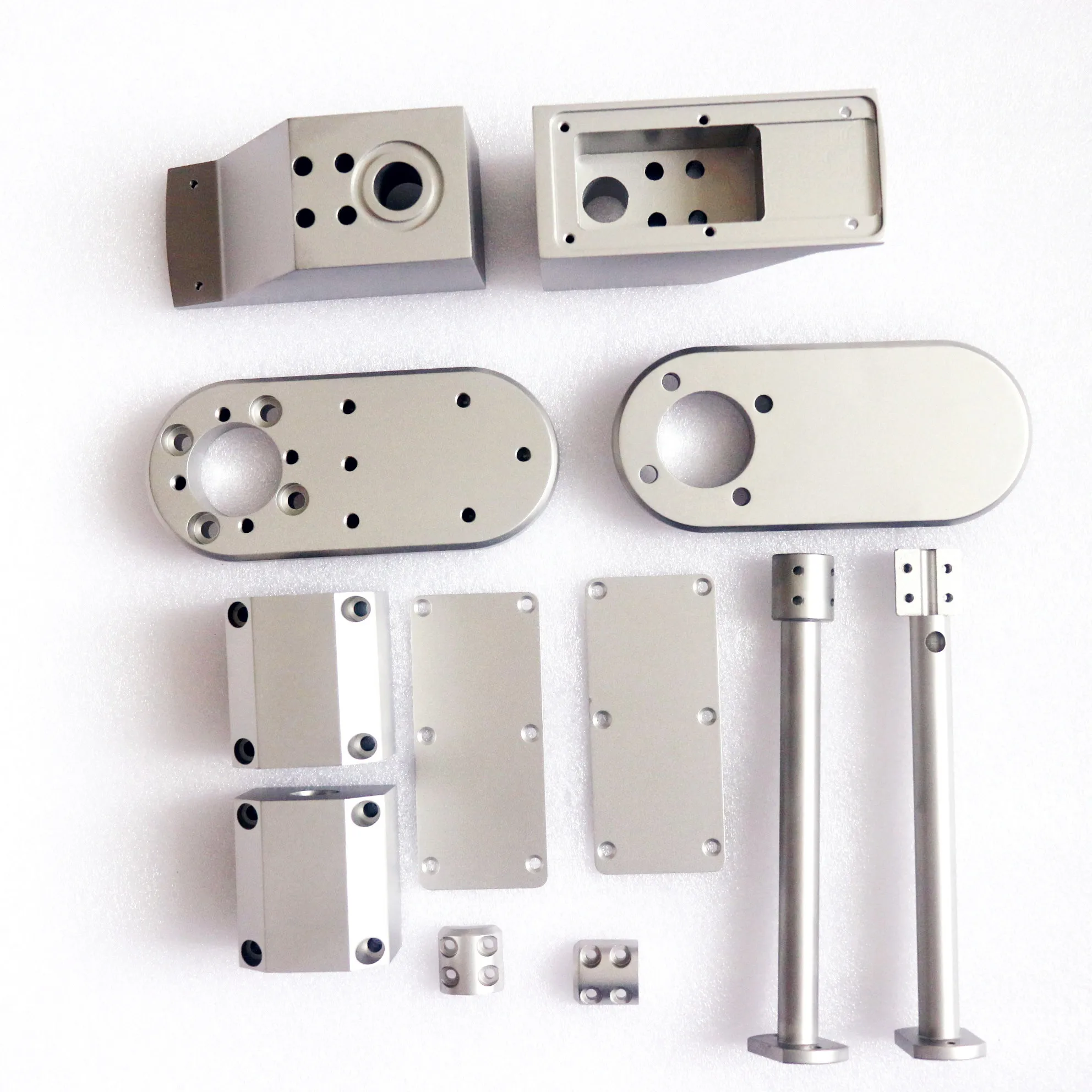

Aluminum parts manufactured by Shenzhen Huarui Century Technology Co., Ltd. are precision-engineered components produced through advanced CNC machining technologies. Aluminum has become one of the most widely used engineering materials across modern industries due to its excellent balance of lightweight properties, mechanical strength, machinability, and corrosion resistance. By combining material expertise with mature CNC milling and turning capabilities, Huarui delivers aluminum parts that meet demanding functional, dimensional, and aesthetic requirements.

From a structural perspective, aluminum parts are well suited for components that must maintain rigidity while minimizing overall weight. This makes them indispensable in industries where dynamic performance, energy efficiency, and ease of handling are critical. Through precise CNC machining, aluminum parts can achieve tight tolerances, consistent wall thicknesses, and complex geometries that are difficult to realize through traditional manufacturing methods.

In terms of performance, aluminum parts offer stable dimensional behavior, good thermal conductivity, and reliable surface integrity. These properties are particularly important for applications involving heat dissipation, mechanical motion, or long-term exposure to varying environmental conditions. Depending on the alloy selection and machining strategy, aluminum parts can be optimized for strength, corrosion resistance, or formability, allowing engineers to tailor components to specific use cases.

Huarui’s aluminum parts are produced under strict quality control procedures, supported by 100% inspection and advanced measurement equipment. With full OEM and ODM support, customized sizes, and flexible production volumes, our aluminum parts are suitable for rapid prototyping, small-batch manufacturing, and stable series production. This versatility enables customers to shorten development cycles while maintaining consistent quality standards.

One of the most significant advantages of aluminum parts is their wide compatibility with different aluminum alloy grades. Depending on performance requirements, aluminum parts can be produced using easy-to-machine alloys such as 6061, high-strength alloys like 7075, or high-ductility alloys such as 5083. This flexibility allows designers to balance mechanical strength, corrosion resistance, machinability, and cost efficiency within a single manufacturing platform.

By selecting the appropriate alloy, aluminum parts can be optimized for structural strength, fatigue resistance, or environmental durability. This adaptability makes aluminum parts suitable for both functional load-bearing components and precision structural elements.

Aluminum parts play a central role in lightweight engineering solutions. With a density significantly lower than steel, aluminum enables substantial weight reduction without sacrificing structural performance. This is particularly valuable in aerospace components, drones, robotics, automation systems, and other applications that require high dynamic response and energy efficiency.

Through CNC machining, aluminum parts can integrate ribs, pockets, and optimized wall structures that further reduce weight while maintaining rigidity. This design freedom makes aluminum parts a core manufacturing solution for advanced lightweight systems.

Aluminum parts are an ideal solution for rapid prototyping and small-to-medium batch production. CNC machining eliminates the need for expensive tooling, allowing designs to be converted into physical components quickly and efficiently. This is especially important during product development stages, where frequent design iterations are required.

For pilot production and customized industrial components, aluminum parts offer a cost-effective path from concept to functional testing. The ability to adjust programs quickly ensures that design changes can be implemented without delays, supporting faster decision-making and reduced time to market.

Aluminum is known for its excellent machinability, which contributes to shorter cycle times, lower tool wear, and consistent surface finishes. Aluminum parts can achieve smooth surfaces suitable for direct use or further surface treatments such as anodizing, polishing, or coating.

This combination of machinability and surface quality ensures that aluminum parts meet both functional and aesthetic requirements, making them suitable for visible components as well as internal structural parts.

The customization process for aluminum parts begins with a detailed review of customer requirements. Technical drawings, material preferences, tolerance expectations, and application environments are carefully evaluated. This step ensures that the selected aluminum alloy and machining strategy align with functional and performance needs.

Engineering feedback at this stage helps optimize manufacturability, reduce unnecessary costs, and prevent potential quality risks before production begins.

Based on application demands, the most suitable aluminum alloy is selected to balance strength, weight, corrosion resistance, and machinability. Process planning then defines the machining route, including milling, turning, drilling, and secondary operations.

Fixture design and tool selection are optimized to ensure dimensional stability and repeatability, especially for aluminum parts with complex geometries or thin-wall structures.

Aluminum parts are produced using advanced CNC milling and turning equipment under controlled machining parameters. Precision toolpaths ensure consistent material removal and stable tolerances throughout production.

Dimensional control is maintained through in-process checks and final inspections, ensuring that each aluminum part conforms strictly to drawing requirements.

Every aluminum part undergoes strict quality inspection using professional measuring equipment such as CMM, height gauges, and surface roughness testers. This ensures dimensional accuracy, surface integrity, and consistency across batches.

Inspection records can be provided upon request, supporting traceability and quality assurance for downstream assembly or certification needs.

Customized packaging solutions are applied to protect aluminum parts during transportation. Delivery schedules are coordinated to align with customer production timelines, ensuring reliable supply and smooth integration into subsequent manufacturing stages.

| Parameter | Specification |

|---|---|

| CNC Machining | CNC Machining |

| Micro Machining | Supported |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Place of Origin | Guangdong, China |

| Brand Name | HUARUI |

| Type | Broaching, Drilling, Chemical Machining, Laser Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

| Size | Customized Size |

| Color | Customized Color |

| Tolerance | According to Customer Drawing Request |

| Material | Customer’s Requirement |

| OEM / ODM | Accepted |

| Quality Control | 100% Inspection |

For aluminum parts projects, early technical communication is essential to ensure optimal results. By sharing drawings, application details, and performance expectations, customers enable efficient evaluation and accurate manufacturing planning.

Professional support throughout the project lifecycle helps ensure stable quality, reliable delivery, and long-term cooperation.

Aluminum parts are widely used in aerospace, robotics, automation, electronics, automotive components, and industrial equipment due to their lightweight and versatile properties.

Yes. Depending on functional requirements, different aluminum alloys can be applied to different components within the same project.

Yes. Aluminum naturally forms a protective oxide layer, and surface treatments such as anodizing can further enhance corrosion resistance.

With CNC machining, aluminum parts can achieve tolerances up to ±0.01 mm, depending on design and application.

Yes. Aluminum parts can be provided with various surface treatments to meet functional or aesthetic requirements.