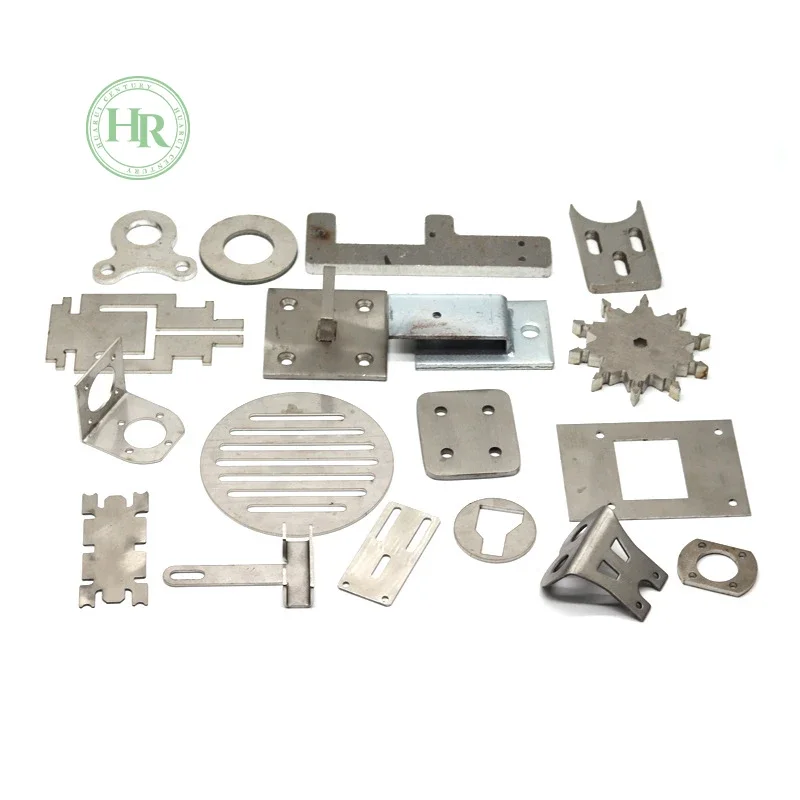

Sheet metal laser cutting service offered by Shenzhen Huarui Century Technology Co., Ltd. provides precision fabrication for a wide range of metal sheets, including stainless steel, aluminum, cold-rolled steel, and galvanized sheets. This service is essential for transforming flat sheet materials into highly accurate, intricate parts used across industrial, commercial, and technological applications.

Huarui’s laser cutting process supports both prototype and large-scale production, delivering components that meet demanding dimensional and quality requirements. The service is widely applied in industries such as electronics, automotive, machinery, aerospace, and architectural metalwork.

The company utilizes advanced CNC laser cutting machines capable of handling customized thicknesses, sheet sizes, and complex geometries. Laser cutting ensures minimal material deformation, excellent edge quality, and high repeatability. The process is compatible with various surface treatments, including polishing, powder coating, and anodizing, providing corrosion resistance, durability, and aesthetic finish.

Huarui also offers a comprehensive service scope that includes design consultation, material selection, processing, assembly, and full OEM solutions. All operations are conducted under ISO9001-certified quality management systems, ensuring precision, consistency, and compliance with international standards.

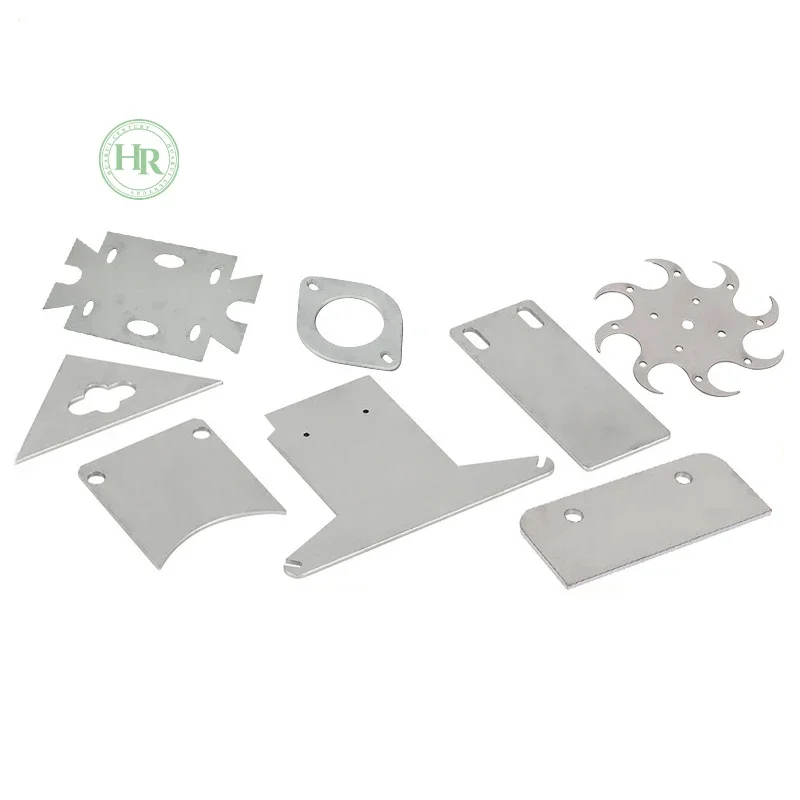

Huarui’s laser cutting service excels in delivering precise, intricate cuts with tolerances down to sub-millimeter levels. The focused laser beam allows for cutting detailed patterns, small holes, sharp internal corners, and complex geometries that are difficult to achieve with traditional mechanical punching or shearing methods.

This precision ensures that parts fit perfectly in assembly processes, reduces post-processing time, and minimizes errors in high-accuracy applications. The service is ideal for creating components for electronics enclosures, machine panels, precision brackets, and decorative metalwork.

Laser cutting is a non-contact process, which eliminates the mechanical forces applied to the workpiece during cutting. This prevents material distortion, warping, and residual stress, particularly beneficial for thin sheets, pre-processed materials, and delicate or flexible metals.

Without tool wear affecting the cut quality, Huarui can provide consistent results across both prototypes and large production runs. This non-contact approach also enhances safety by reducing tool breakage risks and minimizing handling.

The laser cutting process produces smooth, burr-free edges and minimal heat-affected zones. Often, cut parts are ready for assembly immediately, requiring little to no secondary operations such as deburring, grinding, or polishing. This efficiency reduces production costs and accelerates project timelines.

The high-quality edge finish and precise contour control also allow for enhanced functionality, aesthetic appeal, and compatibility with downstream processes like bending, welding, or assembly.

Huarui supports a wide range of materials, including stainless steel, aluminum, galvanized steel, and cold-rolled sheets. Each material type is processed with optimized laser parameters to prevent melting, discoloration, or structural compromise.

Clients can provide CAD, PDF, or 3D drawings, enabling the production of highly customized components. The combination of laser cutting with bending, stamping, and welding processes offers a one-stop fabrication solution for complex sheet metal assemblies.

Design Submission and Review – Clients submit CAD, PDF, or 3D design files. Huarui engineers analyze feasibility, material suitability, and bending/assembly considerations.

Material Selection – Recommended sheet materials are selected according to mechanical requirements, thickness, surface finish, and intended use.

Laser Cutting Preparation – CNC laser cutting parameters, such as power, speed, and focus, are optimized for material type and thickness to ensure precision and minimal thermal effect.

Precision Cutting – Laser cutting machines execute the cutting operations, producing highly accurate parts with smooth edges and intricate geometries.

Secondary Operations – If required, additional processes such as bending, welding, or stamping are applied to complete the part as per design specifications.

Surface Treatment – Polishing, powder coating, or anodizing can be applied to enhance appearance, corrosion resistance, and durability.

Inspection and Quality Control – Dimensional accuracy, edge quality, and overall integrity are verified using tools such as CMM, gauges, and visual inspections. Inspection reports can be provided.

Packaging and Delivery – Finished parts are carefully packed according to client requirements, ensuring protection during transit and clear labeling for easy identification.

This structured workflow ensures that each laser-cut sheet metal part meets design intent, functional requirements, and industry standards.

| Parameter | Specification |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | hr |

| Model Number | hr |

| Product Name | Laser Cutting Service, Stamping Service, Bending Service |

| Material | Customized Sheet Metal |

| Color | Customized Color |

| Size | Customer’s Drawings |

| Tolerance | Customer’s Drawing Request |

| Packing | Customized Packing |

| Surface Treatment | Customer Request |

| Certificate | ISO9001, ISO2008, CE, SGS |

| Thickness | Customized Thickness |

| Type | Laser Cutting Parts |

| Processing | Laser Cutting, CNC Punching, CNC Bending, Stamping, Welding |

| Drawing Format | CAD, PDF, 3D, ETC. |

For professional consultation or quotations for sheet metal laser cutting service, contact Shenzhen Huarui Century Technology Co., Ltd. Submit your drawings, specifications, and material requirements. Huarui provides tailored solutions, technical guidance, and high-quality manufacturing services with prompt delivery.

We process stainless steel, aluminum, cold-rolled sheets, galvanized steel, and other customized metal materials.

Thicknesses are fully customizable. Laser parameters are optimized for each material to ensure clean, precise cuts without deformation.

Yes. The CNC laser cutting equipment enables cutting intricate patterns, sharp corners, and small apertures with high precision and minimal thermal effect.

Often, parts can be used directly due to smooth edges and minimal heat-affected zones. If needed, deburring, polishing, or coating can be applied.

All parts are produced according to customer drawings and specifications. Rigorous inspections ensure adherence to dimensional tolerances and edge quality standards.