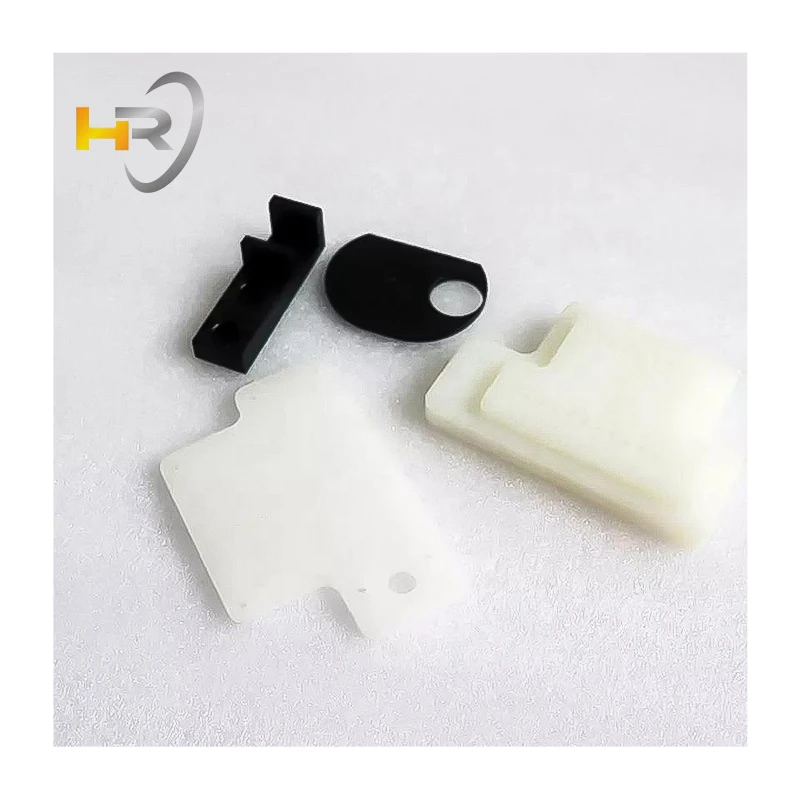

Plastic parts from Shenzhen Huarui Century Technology Co., Ltd. are precision-engineered components manufactured through advanced CNC machining, milling, turning, and multi-axis compound processing. These parts are designed for a wide range of industrial applications, from functional prototypes to small- and medium-batch production components. CNC-machined plastic parts ensure high dimensional accuracy, excellent surface finish, and repeatable performance, making them a critical solution for engineers and designers requiring reliable plastic components.

Plastic materials used in Huarui’s production include POM (acetal), Nylon, ABS, polycarbonate, polypropylene, and other engineering plastics. These materials offer unique properties such as low friction, self-lubrication, chemical resistance, and impact toughness. The combination of advanced CNC machining capabilities and material performance enables the creation of highly complex geometries, intricate details, and precision assemblies.

Structurally, CNC plastic parts provide stability under mechanical stress, lightweight solutions for dynamic assemblies, and excellent insulation properties for electrical and electronic applications. They can be designed with tight tolerances, smooth surfaces, and intricate channels, making them ideal for components like sliding guides, gears, bushings, housings, and functional prototypes. Huarui supports both OEM and ODM services, allowing customers to produce plastic parts according to detailed drawings or functional requirements.

All plastic parts undergo stringent quality control procedures, including dimensional verification, surface finish inspection, and mechanical property testing. This ensures consistent quality and compliance with design specifications, making Huarui a trusted partner for industries including automotive, electronics, medical devices, consumer products, and robotics.

A significant advantage of CNC-machined plastic parts is the inherent low friction and self-lubricating properties of materials like POM, Nylon, and UHMW. These characteristics allow components to function as bearings, sliders, gears, and other moving parts without requiring additional lubricants. This feature reduces maintenance costs, simplifies assembly processes, and improves the operational lifespan of mechanical systems.

By selecting the appropriate plastic material, designers can optimize performance for low-noise and wear-resistant applications. Self-lubricating plastics are particularly advantageous in environments where traditional lubrication is impractical or could contaminate surrounding components, such as in medical devices, food processing machinery, or high-precision instrumentation.

Huarui’s CNC machining capabilities allow for the production of plastic parts with tight tolerances, often down to ±0.01 mm, depending on geometry and material. Complex three-dimensional structures, internal channels, threads, and detailed surface features can be precisely manufactured, making these parts suitable for functional prototypes, mechanical assemblies, and intricate design components.

CNC machining is especially valuable for low- to medium-volume production, as it avoids the need for expensive molds or tooling, reduces lead times, and allows rapid iteration based on design feedback. Parts maintain dimensional stability, repeatable quality, and smooth surface finishes, ensuring consistency for assembly and performance.

Plastic parts serve as ideal materials for functional prototypes that simulate the final product in terms of mechanical behavior, visual appearance, and assembly fit. CNC machining enables quick transformation from CAD design to physical prototype, facilitating design verification, fit checks, and functional testing before committing to larger production volumes.

These functional prototypes allow engineers and designers to test ergonomics, mechanical performance, and assembly procedures, reducing the risk of design flaws and shortening development cycles. Rapid prototyping with plastics accelerates product development, supports iterative improvements, and provides tangible validation for clients or end users.

Huarui’s selection of plastic materials covers a broad spectrum of mechanical and thermal properties. POM and Nylon offer high wear resistance and self-lubrication, ABS provides impact resistance and aesthetic surface quality, polycarbonate offers transparency and toughness, and polypropylene delivers chemical resistance. This versatility ensures that CNC-machined plastic parts can be tailored to meet specific operational requirements, including electrical insulation, thermal resistance, mechanical strength, and dimensional stability.

The flexibility of plastic materials also enables integration with metal or composite assemblies, producing hybrid components optimized for weight, strength, and cost. Complex assemblies can include threaded inserts, embedded metal components, or multi-material configurations, expanding application possibilities across industries.

Customers provide technical drawings or specifications, including functional requirements, load conditions, environmental factors, and surface finish expectations. Based on these inputs, Huarui’s engineering team recommends suitable plastic materials that balance performance, cost, and manufacturability.

The design team evaluates the geometry for manufacturability, tolerance compatibility, and potential deformation under machining stress. Feedback is provided to optimize part design for CNC machining, ensuring dimensional stability and minimizing post-processing requirements.

A small batch of CNC-machined plastic parts is produced for functional testing and inspection. Dimensional checks, surface finish verification, and mechanical performance tests are conducted to ensure prototype compliance with customer expectations.

Once prototypes are approved, production is scheduled. CNC machining is performed using high-precision equipment, with in-process inspection and testing conducted at each stage. Quality control includes measurements with CMM, dial gauges, surface roughness assessment, and other precision instruments to guarantee adherence to tolerances and specifications.

After machining, plastic parts can undergo additional treatments such as polishing, deburring, surface coating, or texturing, depending on application requirements. Parts are then carefully packaged to prevent damage during transportation and labeled for traceability.

Completed plastic parts are shipped according to the agreed delivery schedule. Huarui provides technical support and addresses any post-delivery issues, ensuring customer satisfaction and reliable long-term use.

| Parameter | Specification |

|---|---|

| CNC Machining | CNC Machining |

| Micro Machining | Supported |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Place of Origin | Guangdong, China |

| Brand Name | HUARUI |

| Type | Broaching, Drilling, Chemical Machining, Laser Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

| Size | Customized Size |

| Color | Customized Color |

| Tolerance | According to Customer Drawing Request |

| Material | Customer’s Requirement |

| OEM / ODM | Accepted |

| Quality Control | 100% Inspection |

For CNC-machined plastic parts, providing detailed drawings and functional requirements ensures accurate quotations, optimal material selection, and efficient production planning. Huarui’s technical team is available to assist with design optimization, material recommendations, and cost-effective manufacturing strategies.

Contact us to discuss your project requirements, obtain a quote, or request a sample for evaluation. Professional support is provided throughout the design, production, and delivery process to guarantee high-quality, reliable plastic parts.

Huarui offers POM, Nylon, ABS, Polycarbonate, Polypropylene, and other engineering plastics, selected according to application needs.

Yes. Materials such as POM and Nylon provide self-lubrication, low friction, and high wear resistance, making them suitable for bearings, gears, and sliders.

Typical tolerances are ±0.01 mm, depending on geometry, material, and machining complexity.

Yes. CNC-machined plastic parts are ideal for functional prototypes, allowing testing of fit, assembly, and mechanical performance before mass production.

Yes. Options include deburring, polishing, surface coating, texturing, or laser engraving to meet functional or aesthetic requirements.