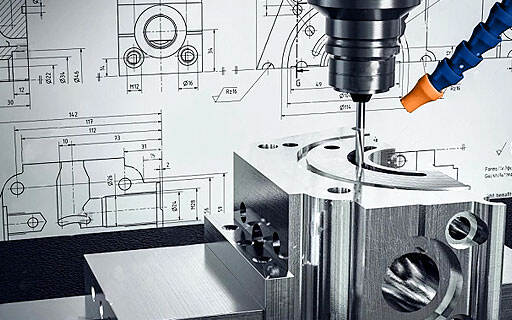

CNC Machining: Precision Manufacturing from a Digital File It is a versatile manufacturing service characterized by:

Precision & Accuracy (for parts with tight tolerances)

Complex Geometries (capable of creating intricate shapes)

Excellent Consistency (ideal for both prototypes and mass production)

Material & Application Versatility (works with various metals and plastics)

CNC machining is a manufacturing process that uses software code to control machine tool operations, transforming raw materials into parts. Engineers create a three-dimensional model of the part, defining its geometric features and dimensions. After analysis, they generate code by setting toolpaths, cutting parameters, and processes. During the machining phase, the operator loads the material onto the machine tool's worktable and installs the cutting tools. Once the program is started, the machine tool runs automatically. The spindle drives the cutting tool to rotate at high speed, while the motor drives the tool and worktable to perform cutting, drilling, milling, and other operations along the coordinate axes, revealing the part's shape. After machining, the part undergoes deburring, polishing, or surface treatment processes, and is inspected using measuring equipment to ensure its performance meets specifications.

CNC machining, with its high precision, high stability, and superior ability to handle complex parts, has become a core technology in modern manufacturing. It is widely used in many key fields: in the aerospace industry, it is used to manufacture key components such as engine blades and fuselage structural parts; in the medical device field, it is used for precision machining of surgical instruments, artificial joints, and other implants; in the automotive manufacturing industry, it is used to produce core engine components and transmission system gears; in the electronics and communications field, it is used to machine precision structural parts such as 5G base station housings and mobile phone metal frames; and it also plays an irreplaceable role in energy equipment, military industry, and mold manufacturing.

CNC turning is a machining process that uses computer programs to control machine tools, causing the material to rotate while cutting with fixed cutting tools, thereby precisely manufacturing rotating parts such as shafts and sleeves.

CNC milling is a precision manufacturing process that uses a computer-controlled multi-axis linkage system to precisely cut a stationary workpiece with a rotating cutting tool, thereby machining complex three-dimensional contours, cavities, and planes.

Our company mainly provides customers with high-quality products and reliable services, so as to save customers' time and cost.

After you send your inquiry, our professional team will communicate with you. After understanding your needs, our engineers will provide a quote for the products you require.