Brass parts produced by Shenzhen Huarui Century Technology Co., Ltd. are precision-engineered components manufactured through advanced CNC machining processes, including milling, turning, drilling, and multi-axis compound machining. Brass, as a copper–zinc alloy, is widely recognized for its excellent machinability, stable mechanical properties, and superior surface finish, making it one of the most efficient materials for high-precision and high-volume CNC machining applications.

From a material performance perspective, brass parts combine moderate strength with outstanding cutting performance. During machining, brass generates short, easily controlled chips, allowing higher spindle speeds and feed rates without compromising dimensional accuracy or tool life. This characteristic makes brass parts particularly suitable for cost-sensitive projects that still require tight tolerances and consistent quality.

Structurally, brass parts maintain good dimensional stability under normal operating conditions and exhibit reliable performance in mechanical assemblies. Their natural corrosion resistance in atmospheric and mildly corrosive environments ensures long service life without extensive surface protection. This makes brass parts a preferred choice for components used in plumbing systems, electrical connectors, instrumentation, and decorative hardware.

At Huarui, brass parts are manufactured under strict quality control standards, supported by 100% inspection and professional metrology equipment. OEM and ODM services are fully supported, enabling customers to obtain brass parts in customized sizes, shapes, and finishes according to specific drawings or functional requirements. Whether for rapid prototyping, small-batch customization, or stable series production, Huarui’s brass parts provide a reliable and efficient manufacturing solution.

One of the most prominent advantages of brass parts is their exceptional economic efficiency during CNC machining. Brass allows the use of very high spindle speeds and feed rates, significantly increasing material removal rates. Compared with harder or more abrasive metals, brass causes minimal tool wear, which extends tool life and reduces tooling costs over long production runs.

This machining efficiency directly translates into higher output per unit time and lower cost per part. For customers requiring medium- to large-volume production, brass parts offer a highly competitive balance between performance and manufacturing cost.

Brass parts excel in the reliable production of fine details. CNC machining of brass enables the creation of precise threads, thin walls, complex internal grooves, sharp edges, and even micro-scale markings or text. The material’s cutting stability ensures that these features are formed cleanly, without burrs or deformation.

This high level of detail reproduction is critical for applications such as precision connectors, valve components, fasteners, decorative hardware, and electronic terminals, where dimensional accuracy and surface definition directly affect functionality and assembly performance.

Brass parts offer good ductility, allowing them to undergo secondary operations such as bending, riveting, press-fitting, or light forming without cracking. This flexibility supports multi-stage manufacturing processes and complex assembly requirements.

In addition, brass is highly compatible with a wide range of surface treatments. Brass parts can be electroplated with nickel, chromium, gold, or other coatings to enhance corrosion resistance, electrical conductivity, or visual appeal. They can also be passivated or protected with clear lacquer coatings, making brass parts suitable for both functional and decorative applications.

Brass parts provide consistent mechanical performance, including adequate strength, wear resistance, and vibration damping. Many brass alloys also offer good electrical conductivity, making them suitable for electrical and electronic components where reliable signal transmission or grounding is required.

This combination of mechanical stability and electrical performance expands the applicability of brass parts across multiple industries.

Brass parts are widely used in electrical and electronic applications due to their good electrical conductivity, corrosion resistance, and dimensional stability. Typical brass parts include terminals, connectors, contact pins, grounding components, and switch elements. Precision machining ensures tight tolerances, which are essential for reliable electrical contact and consistent performance.

Surface treatments such as nickel or gold plating can further enhance conductivity and oxidation resistance, making brass parts suitable for long-term use in demanding electrical environments.

In plumbing and fluid control systems, brass parts are valued for their resistance to corrosion, good sealing performance, and compatibility with water and mild chemicals. Common applications include valve bodies, fittings, couplings, nozzles, and pump components.

The machinability of brass allows complex internal channels and threads to be produced with high accuracy, ensuring leak-free connections and stable flow control.

Brass parts are frequently used in mechanical assemblies where precision, smooth motion, and wear resistance are required. Examples include bushings, spacers, sleeves, gears, and guide components. Brass’s natural lubricity reduces friction between moving parts, contributing to smoother operation and reduced maintenance requirements.

These characteristics make brass parts suitable for instruments, automation equipment, and precision machinery.

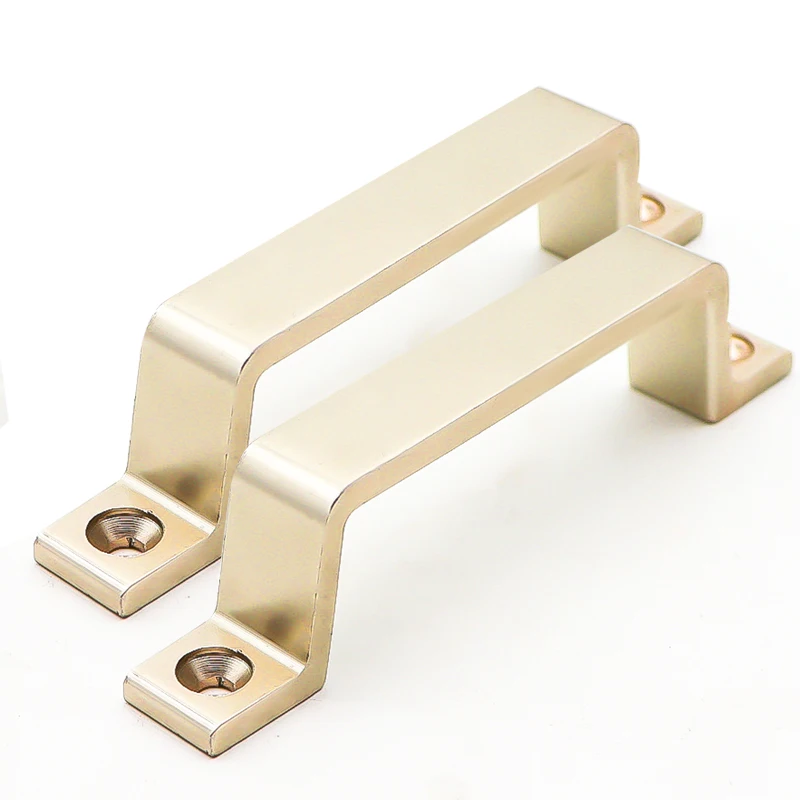

Thanks to its attractive natural color and excellent surface finish, brass is a popular material for decorative hardware. Brass parts are commonly used in door handles, knobs, fittings, lighting components, and ornamental fixtures. CNC machining allows these brass parts to achieve consistent shapes and refined details, supporting both functional and aesthetic requirements.

With appropriate surface finishing, brass parts can maintain long-lasting visual appeal in interior and exterior applications.

In automotive and industrial equipment, brass parts are used in fuel systems, sensors, cooling components, and control mechanisms. Their resistance to vibration, stable performance, and ease of machining make them suitable for precision-critical components that must perform reliably over extended service life.

| Parameter | Specification |

|---|---|

| CNC Machining | CNC Machining |

| Micro Machining | Supported |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Place of Origin | Guangdong, China |

| Brand Name | HUARUI |

| Type | Broaching, Drilling, Chemical Machining, Laser Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

| Size | Customized Size |

| Color | Customized Color |

| Tolerance | According to Customer Drawing Request |

| Material | Customer’s Requirement |

| OEM / ODM | Accepted |

| Quality Control | 100% Inspection |

For brass parts projects, providing complete drawings, material preferences, and application details enables efficient technical evaluation and accurate quotation. Early-stage communication helps optimize machining methods, reduce unnecessary costs, and ensure consistent quality throughout production.

Professional engineering support is available to assist with design validation, material selection, and production planning.

Brass parts offer superior machinability, better corrosion resistance in mild environments, and lower machining costs, especially for complex or high-volume components.

Yes. Many brass alloys provide good electrical conductivity and are commonly used for connectors, terminals, and contact components.

Brass parts can be electroplated, passivated, lacquered, or polished to enhance corrosion resistance, appearance, or functional performance.

With CNC machining, brass parts can typically achieve tolerances up to ±0.01 mm, depending on design complexity.

Yes. Due to high machining efficiency and tool life, brass parts are well suited for stable medium- to large-scale production.