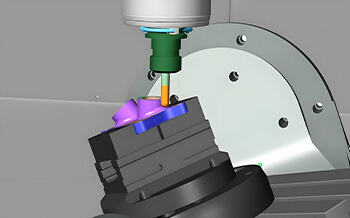

CNC machining services represent a modern manufacturing process that utilizes programmed computer software to precisely control machine tools for cutting operations. It is fundamentally a "subtractive manufacturing" method, which involves strategically removing material from a solid block to yield a final part that matches the digital design.

The workflow begins with a 3D digital model of the product, which is then translated into machine-readable instruction code . Subsequently, the CNC machine, driven by this code, operates automatically. Through operations like milling, turning, and drilling performed by high-speed rotating cutting tools, it transforms the digital blueprint into a high-precision physical entity.

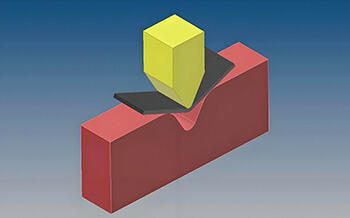

Sheet metal fabrication services encompass a range of cold-working processes for metal sheets, aimed at manufacturing various thin-walled structural components through operations like shearing, punching, bending, and forming. Unlike the "sculpting" nature of CNC machining, it is more akin to "cutting and folding" sheet metal.

The process typically starts with laser cutting or stamping to shear the sheet metal into the required flat pattern. Then, via the bending process, precise press brakes are used to transform the flat sheets into three-dimensional structures. Finally, components are assembled into the final product using methods like welding, riveting, or screwing, often accompanied by surface treatments to enhance appearance and corrosion resistance.

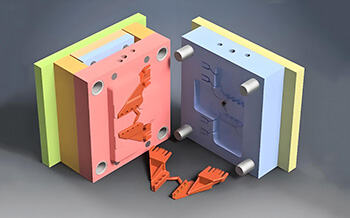

Casting services are a long-established "hot forming" method. The core principle involves pouring molten metal into a pre-made mold cavity, allowing it to cool and solidify, thereby obtaining a rough blank or finished part of the desired shape. This is an "additive forming" process.

The process first requires creating a mold based on the part design. Next, the high-temperature molten metal is poured or injected into the mold cavity and left to cool and solidify. Finally, the mold is broken open or the part is ejected, followed by cleaning and any necessary post-processing.

Delivers exceptional precision and consistency in producing complex components, supporting everything from prototyping to mass production with digital workflow flexibility and broad material compatibility.

Creates lightweight yet robust enclosures and structural parts with high efficiency, offering cost-effective solutions for both rapid prototyping and large-scale manufacturing while supporting diverse surface treatments.

Enables production of large-scale or intricately shaped components with complex internal features, providing remarkable design freedom and low per-part cost for high-volume orders through near-net-shape manufacturing.