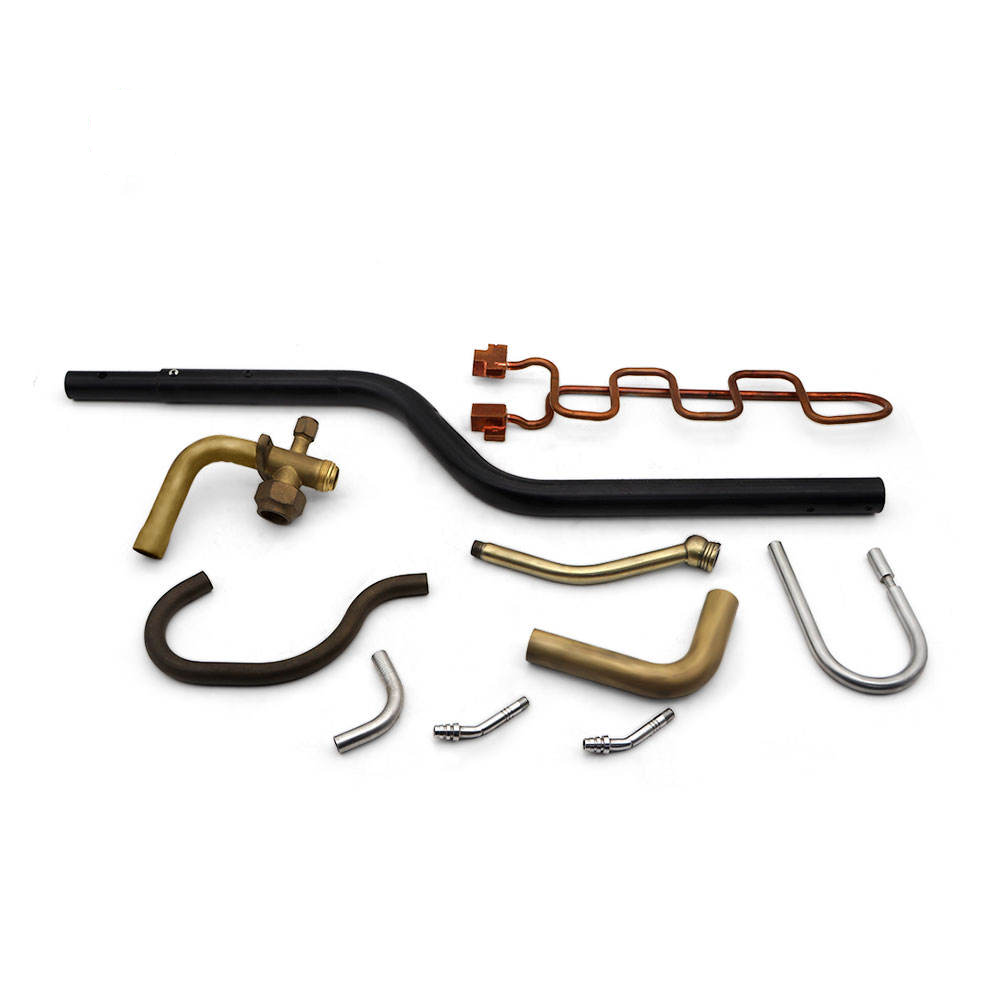

Sheet metal bending service provided by Shenzhen Huarui Century Technology Co., Ltd. encompasses precision bending and forming of various metal sheets, including stainless steel, aluminum, galvanized steel, and cold-rolled steel. This service is essential for transforming flat sheet materials into complex three-dimensional components for industrial, commercial, and consumer applications.

Huarui’s sheet metal bending capabilities support high-precision, customizable solutions for prototypes, small batch production, and large-scale manufacturing. The service includes CNC bending, stamping, and welding to meet design specifications, tolerances, and aesthetic requirements. Components can range from structural supports, brackets, and enclosures to intricate housings for electronics, machinery, and appliances.

The company’s expertise extends to handling complex geometries, multiple bend angles, and intricate cutouts, ensuring consistency, dimensional accuracy, and smooth surface quality. Sheet thicknesses, bend radii, and tolerances are customizable according to customer drawings and specifications. Surface treatments, such as polishing, powder coating, anodizing, or passivation, are available to enhance corrosion resistance, wear resistance, or aesthetic appeal.

Huarui offers full OEM services, providing design consultation, material recommendations, and comprehensive manufacturing solutions. With ISO9001 certification and rigorous quality inspections, every bent sheet part meets international standards, ensuring reliability for critical industrial applications.

Huarui’s sheet metal bending service provides high-precision forming of complex sheet geometries. CNC bending machines ensure accurate bend angles, consistent dimensions, and repeatability across production batches. The company can process custom sizes and materials, allowing clients to implement specialized designs and tight tolerances for both prototype and series production.

Custom bending enables the creation of intricate parts with multiple bend lines, flanges, and channels in a single piece. This reduces assembly steps, improves structural integrity, and minimizes errors caused by welding or mechanical fasteners. The service also supports integration with other processes, such as laser cutting or stamping, providing one-stop sheet metal fabrication solutions.

Huarui supports a wide range of sheet materials, including stainless steel, aluminum, cold-rolled steel, and galvanized sheets. Each material is processed with specific bending parameters, optimized to maintain strength, prevent cracking, and reduce spring-back effects.

The combination of laser cutting, CNC punching, stamping, and bending allows seamless production of components with precise cutouts, holes, and contours, reducing secondary operations and assembly complexity. This flexibility ensures that clients can fabricate parts for diverse applications, from enclosures and panels to structural supports and decorative elements.

For design verification, functional testing, or low-volume manufacturing, Huarui’s bending service provides rapid prototyping capabilities. The combination of CAD/CAM integration, automated CNC bending, and skilled programming allows fast turnaround from design files to finished parts.

Clients benefit from the ability to test and iterate designs quickly, adjusting angles, dimensions, and features without expensive tooling changes. Small batch production is cost-efficient due to minimal setup times, automated process control, and optimized material usage, making the service ideal for startups, R&D departments, and custom industrial solutions.

All bent sheet components undergo thorough inspection, including dimensional verification, bend angle measurement, and surface quality checks. Surface treatments, such as anodizing, powder coating, or polishing, enhance durability, corrosion resistance, and visual appeal. Huarui ensures that each part complies with ISO9001 standards and client specifications, providing reliable, long-lasting sheet metal components.

Design Review and Consultation – Clients provide CAD drawings, PDFs, or 3D models. Huarui engineers analyze the design for manufacturability, material compatibility, and optimal bending sequences.

Material Selection – Appropriate sheet material is recommended based on mechanical requirements, thickness, surface finish, and application environment.

Laser Cutting or Punching – Sheets are cut with high precision to prepare for bending. Laser cutting ensures clean edges, minimal burrs, and accurate holes or contours.

CNC Bending – Automated bending machines execute precise angle formation. Parameters such as bend radius, force, and sequence are optimized to prevent deformation, cracking, or spring-back.

Secondary Operations – Stamping, welding, or additional forming processes are performed as needed, integrating multiple operations in one workflow to reduce assembly requirements.

Surface Treatment – Polishing, anodizing, or coating is applied to meet corrosion resistance, mechanical, or aesthetic requirements.

Inspection and Quality Control – Dimensional accuracy, bend angles, and surface integrity are verified through manual and automated inspections. Reports are provided for client verification.

Packaging and Delivery – Parts are carefully packed according to specifications and shipped with proper labeling, documentation, and traceability.

This structured process ensures high-quality, reliable bent sheet components that meet diverse industrial demands.

| Parameter | Specification |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | hr |

| Model Number | hr |

| Product Name | Laser Cutting Service, Stamping Service, Bending Service |

| Material | Customized Sheet Metal |

| Color | Customized Color |

| Size | Per Customer Drawings |

| Tolerance | Customer's Drawing Request |

| Packing | Customized Packing |

| Surface Treatment | Per Customer Requirement |

| Certificate | ISO9001 |

| Thickness | Customized Thickness |

| Type | Laser Cutting Parts, CNC Bending, Stamping, Welding |

For professional consultation or quotations for sheet metal bending service, please contact Shenzhen Huarui Century Technology Co., Ltd. Submit your drawings, specifications, and material requirements. Huarui provides tailored solutions, technical guidance, and reliable manufacturing services with timely delivery.

We support stainless steel, aluminum, galvanized steel, cold-rolled sheets, and other customized materials based on your requirements.

Thicknesses are customizable according to customer specifications, with optimized bending parameters for each material to prevent defects.

Yes. CNC bending equipment and skilled operators enable multi-angle bends, channels, flanges, and intricate designs with high precision.

Yes. Laser cutting, stamping, welding, and surface finishing can be integrated with bending to provide a complete sheet metal fabrication solution.

Tolerances are maintained according to customer drawings and specifications. Huarui performs strict inspections using gauges, angle measurement tools, and quality control procedures.