Manufacturer Custom Aluminum Pipe Stainless Steel Hollow Tube Bending Metal Stainless Steel Pipe Bending Service

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Name |

custom manufacturing sheet metal fabrication parts service |

Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Processing |

Stamping ,Sheet metal fabrication |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Our Advantages |

1.) 24 hours online service & Quickly Quote/Delivery.

2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) To provide production design, production and technical service, mould development and processing, etc |

You are very welcome to visit us among many suppliers

2.) 24 hours online service & Quickly Quote

3.) We have very rich experience, you are welcome to discuss with us at any time your requirements or products that you need to customize.

4.) 100% QC quality inspection before delivery, and can provide quality inspection form.

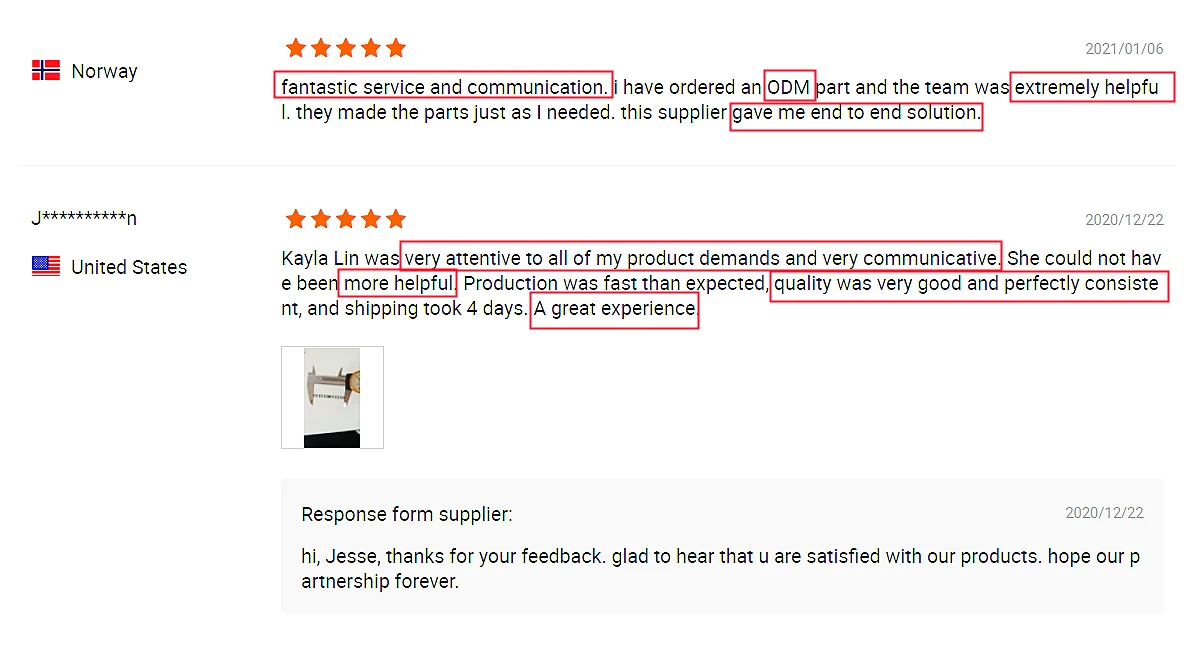

5.) Our products and services have been widely praised by customers at home and abroad

6.) ISO certificate Factory

7.)In order to allow you to receive goods more quickly and conveniently, we support sea, land, express and air transportation

Product Overview

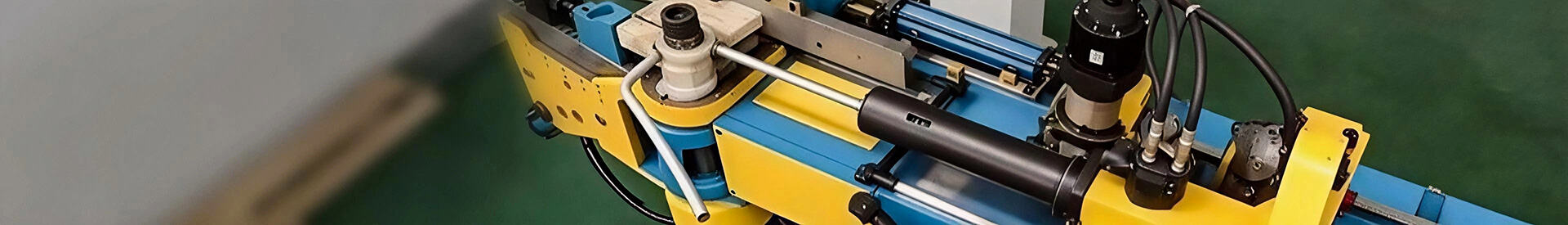

Shenzhen Huarui Century Technology Co., Ltd. offers customized bending services for aluminum pipes and stainless steel hollow tubes, providing precision-engineered components for industrial, automotive, aerospace, and construction applications. Utilizing advanced CNC tube bending technology, we ensure high dimensional accuracy, smooth surface finishes, and consistent performance, making our products suitable for both prototype development and large-scale production.

-

Precision Bending Technology: Our CNC bending systems enable the production of complex bends, multi-radius curves, and custom geometries, maintaining the integrity of the tube without deformation, wrinkling, or flattening.

-

Material Versatility: We work with aluminum, stainless steel, and other high-strength alloys, accommodating various diameters, wall thicknesses, and tube shapes. The resulting components combine lightweight performance, corrosion resistance, and structural strength, meeting rigorous engineering requirements.

-

Small to Large-Scale Production: Shenzhen Huarui supports low-volume custom orders as well as high-volume manufacturing, ensuring consistent quality across batch sizes. Our workflow integrates automated programming, precise mandrel support, and process optimization for efficient production cycles.

-

Surface Quality and Finish: We employ surface protection methods during bending, including protective films and polishing, ensuring scratch-free, visually appealing tubes ready for assembly or integration into complex systems.

-

Wide Applications: Our bent tubes are ideal for piping systems, hydraulic assemblies, handrails, exhaust systems, structural supports, and machinery components, providing durability, precision, and reliability.

With strict quality control procedures, including dimensional checks, bend angle verification, and visual inspections, we deliver high-performance, defect-free tubes suitable for critical applications.

Product Advantages

1. Conversion of Flat Material into Three-Dimensional Structures

Our bending services allow for the transformation of flat metal sheets and tubular stock into complex 3D structures. By leveraging CNC-controlled bending sequences, tubes maintain structural integrity and uniformity, even when multiple bends are required in a single component. This capability is particularly valuable for architectural frameworks, industrial piping assemblies, and custom machinery parts, where precise 3D geometry is critical.

2. High Repeatability and Consistency

Shenzhen Huarui ensures identical results across batches, achieved through programmed CNC bending operations, precise mandrel support, and springback compensation. Every bend meets the specified angle, radius, and dimensional tolerance, which is essential for modular assembly, automated manufacturing, and complex industrial applications.

3. Reduced Production Time with Efficient Processes

Our processes allow for rapid component fabrication, reducing turnaround time without compromising quality. Through optimized bending sequences, automated setup, and high-speed CNC equipment, we can quickly move from prototypes to mass production, satisfying tight project schedules and enabling fast iteration for design modifications.

Production Process

Shenzhen Huarui follows a systematic and reliable tube bending process, ensuring high precision and quality control:

-

Design & Feasibility Assessment: Clients provide CAD files or technical drawings, and our engineers assess bend feasibility, tube material properties, and wall thickness considerations. We determine optimal bend sequences to prevent deformation.

-

Material Inspection & Preparation: Tubes are checked for uniformity, surface quality, and structural integrity. Selected materials undergo pre-cleaning or surface treatment, depending on application requirements.

-

CNC Mandrel Bending: Using state-of-the-art CNC bending machines, tubes are bent to precise angles while maintaining internal wall support and minimizing wrinkling. Multi-radius and multi-bend components are handled seamlessly.

-

Post-Bending Operations: Tubes may undergo end flaring, notching, trimming, or laser cutting to meet assembly specifications. Protective films or coatings are applied to prevent surface damage.

-

Quality Control: Every tube is subjected to 100% inspection, verifying dimensions, bend angles, wall thickness, and surface finish. This ensures adherence to strict tolerance standards.

-

Packaging & Delivery: Finished components are carefully packaged with protective materials to prevent scratches or deformation during transit. Tubes are ready for installation upon arrival.

Request a Quote

Shenzhen Huarui Century Technology Co., Ltd. offers custom solutions for aluminum and stainless steel tube bending, including:

-

Precision bending of hollow tubes and aluminum pipes with strict tolerances.

-

Support for small batch prototypes and high-volume production runs.

-

Advanced surface protection and finishing methods, ensuring ready-to-use components.

-

Integration with additional processes like laser cutting, flaring, notching, and welding.

Submit your drawings and specifications to receive a personalized quote for your tube bending project. Partner with Shenzhen Huarui for reliable, high-quality, precision bent tubes that meet industrial and engineering standards.

Frequently Asked Questions (FAQ)

Q1: What types of tubes do you bend?

A1: We bend round, square, and rectangular tubes made from aluminum, stainless steel, and other alloys.

Q2: What is the maximum bend angle achievable?

A2: Our CNC bending equipment can handle 0° to 180° bends, including multi-radius and compound bends.

Q3: Can you produce both prototypes and high-volume orders?

A3: Yes, Shenzhen Huarui supports low-volume custom projects and full-scale production, maintaining consistent quality across all batch sizes.

Q4: How is deformation prevented during bending?

A4: We utilize mandrel support, rotary draw bending, and springback compensation to ensure smooth, deformation-free bends.

Q5: Are finishing and surface protection services available?

A5: Yes, including polishing, anodizing, powder coating, and protective films during bending to prevent scratches.

Q6: Do you accept custom drawings?

A6: Absolutely. We offer OEM and custom tube bending services, tailored to client specifications.

Q7: How is quality verified?

A7: All tubes undergo dimensional inspection, bend angle verification, and surface assessment, guaranteeing defect-free products.

Q8: Can bending integrate with other operations?

A8: Yes, tubes can be laser cut, notched, flared, or welded as needed for assembly or installation requirements.