OEM CNC Turning Milling Parts CNC Lathe Machining Brass Service Manufacturer Custom Stainless Steel Aluminum CNC Machining Parts

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

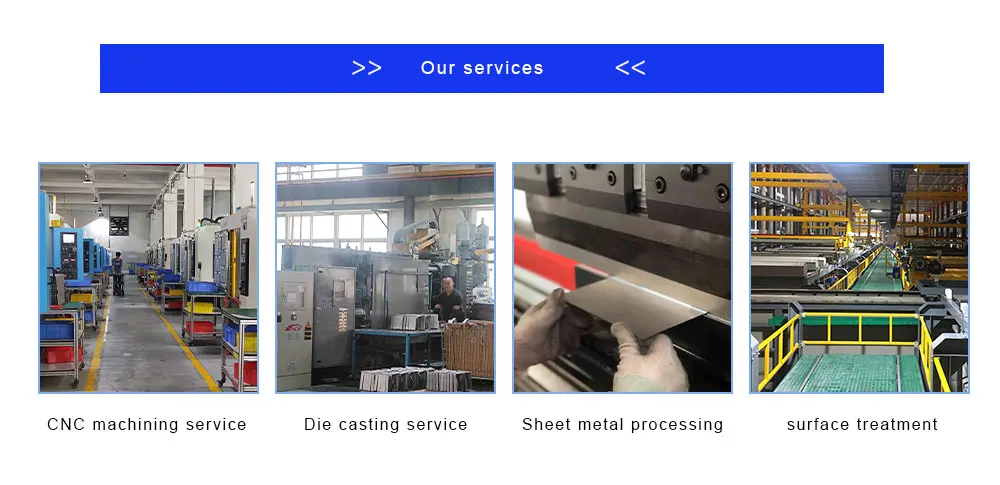

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

You are very welcome to visit us among many suppliers

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Product Overview

OEM CNC Turning and Milling Parts for Precision Applications

Shenzhen Huarui Century Technology Co., Ltd. specializes in high-precision CNC machining services, offering OEM CNC Turning Milling Parts, CNC Lathe Machining, and custom brass, stainless steel, and aluminum components. Our services cater to industries including industrial machinery, automotive, electronics, marine engineering, and instrumentation, where precision, reliability, and material performance are critical.

Advanced CNC Capabilities

Our factory is equipped with state-of-the-art CNC lathes, milling machines, and 5-axis machining centers, allowing for the production of components with complex geometries, tight tolerances, and superior surface finishes. Whether for single prototypes or high-volume production, we can produce custom shafts, gears, housings, and decorative metal parts that meet exacting technical standards.

Material Flexibility and Customization

We work with brass, stainless steel, aluminum, copper, bronze, hardened metals, steel alloys, and precious metals, offering clients full flexibility in material selection, dimensions, tolerances, and finishes. Components are made according to your CAD files, 3D models, or technical drawings, ensuring that every part aligns precisely with design requirements.

Quality Assurance and Reliability

Each part undergoes 100% inspection for dimensional accuracy, surface finish, and material integrity. This guarantees that all products meet stringent performance and quality standards, providing durability and consistent functionality for demanding industrial applications.

Product Advantages

Exceptional Corrosion Resistance

Brass components are renowned for their outstanding resistance to corrosion, particularly in water and humid environments. This makes them ideal for valves, fittings, marine applications, and fluid-handling systems, ensuring long-term durability and minimal maintenance. Our CNC machining process preserves these properties while enabling precision shaping of complex components.

Superior Machinability and Surface Finish

Our CNC brass parts are easily machined with low cutting resistance, producing short, predictable chips and reducing tool wear. This allows for high-speed, high-precision turning and milling, resulting in components with smooth surfaces, excellent tolerances, and intricate detailing. These features are essential for small, high-precision components like gears, connectors, and fittings.

Self-Lubricating and Wear-Resistant Properties

Brass naturally exhibits low friction and self-lubricating characteristics, making it ideal for bushings, bearings, and moving parts. Combined with precision CNC machining, this ensures long-term performance with reduced wear, providing reliable operation in rotational and sliding assemblies. These properties are particularly valued in automotive components, industrial machinery, and precision instruments.

Versatile Decorative and Functional Applications

Brass CNC parts offer a distinctive golden appearance, suitable for decorative hardware, musical instruments, and architectural fittings. CNC machining allows for intricate designs and high-quality finishes, while the material maintains excellent mechanical and electrical properties, enabling both functional and aesthetic versatility.

Wide Industry Applications

Our CNC components are widely used in valve systems, instrumentation, electronics, automotive, and marine industries. They are suited for applications requiring high precision, corrosion resistance, wear resistance, and stable mechanical performance, ensuring that each component meets specific functional and regulatory standards.

Customization and Production Workflow

Step 1: Design Submission

Clients provide technical drawings, CAD files, or 3D models, which our engineering team reviews. We assess feasibility, material selection, and tolerance requirements to ensure the final product aligns with client expectations.

Step 2: Material Selection and Preparation

Materials such as brass, stainless steel, aluminum, and other alloys are selected based on application requirements, corrosion resistance, machinability, and mechanical properties. Raw materials are carefully inspected before machining.

Step 3: CNC Programming and Tooling Setup

Our engineers create custom CNC programs for each part, taking into account geometry, tolerances, and surface finish requirements. Tooling is selected to optimize cutting speed, precision, and surface quality, minimizing tool wear and ensuring repeatable results.

Step 4: Precision CNC Machining

Parts are machined using CNC lathes, milling machines, and multi-axis machining centers, achieving tight tolerances, smooth finishes, and consistent part geometry. Both small, intricate components and larger structural parts can be produced with high precision.

Step 5: Surface Treatment and Finishing

Finished parts may undergo polishing, plating, anodizing, or custom coatings to enhance corrosion resistance, durability, and aesthetic quality. Surface treatments are carefully controlled to maintain mechanical properties and dimensional accuracy.

Step 6: Quality Control and Inspection

Each component undergoes 100% inspection, including dimensional measurement, surface quality verification, and material integrity checks, ensuring only defect-free parts reach our clients.

Step 7: Packaging and Delivery

Components are carefully packaged and labeled, ensuring safe transport. We offer flexible shipping options to meet deadlines and logistical requirements, maintaining full transparency during transit.

Technical Parameters

| Parameter | Specification |

|---|---|

| CNC Machining | Yes |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Stainless Steel, Steel Alloys, Hardened Metals, Precious Metals |

| Place of Origin | Guangdong, China |

| Type | Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining | Yes |

| Model Number | NO |

| Brand Name | HUARUI |

| Size | Customized |

| Color | Customized |

| Tolerance | Customer’s Drawing Request |

| OEM/ODM | Accepted |

| Quality Control | 100% Inspection |

Work With Us

Get Your Custom CNC Brass and Metal Parts

Partner with Shenzhen Huarui Century Technology Co., Ltd. for professional CNC machining services. We specialize in high-precision brass, stainless steel, and aluminum components, including custom shafts, fittings, housings, and decorative elements. Submit your drawings or 3D models to receive a technical assessment, tailored manufacturing plan, and competitive quotation. Experience the precision, durability, and efficiency of our machining services for your next project.

Frequently Asked Questions (FAQ)

Q1: What metals can you machine?

A: We machine brass, aluminum, stainless steel, copper, bronze, steel alloys, hardened metals, and precious metals.

Q2: Can you handle intricate geometries and tight tolerances?

A: Yes. Our CNC lathes and 5-axis machines produce complex shapes with high precision.

Q3: Do you accept prototype or small-batch orders?

A: Yes. We accommodate prototyping and high-volume production according to client needs.

Q4: Are surface finishing options available?

A: Yes. We provide polishing, plating, anodizing, and custom coatings to enhance appearance and durability.

Q5: How is quality control managed?

A: Each part undergoes 100% inspection including dimension checks, material verification, and surface finish assessment.

Q6: Can you manufacture parts based on CAD or 3D models?

A: Absolutely. We accept technical drawings, CAD files, and 3D models, converting them into precise CNC programs.

Q7: Do you provide OEM and ODM services?

A: Yes. We provide custom OEM/ODM solutions, including material selection, surface treatments, and size specifications.