Custom OEM Multicolor Anodizing Brass Keyboard Case Plate CNC Service

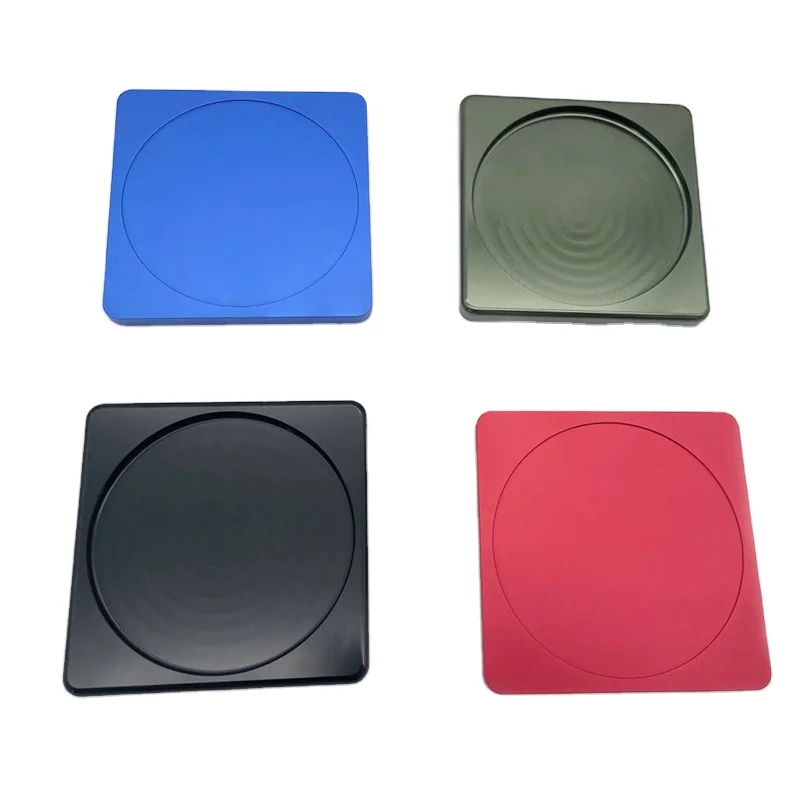

Custom OEM multicolor anodizing brass keyboard case plate CNC machining service from a professional China manufacturer, specializing in precision milled mechanical keyboard panels with vibrant anodized finishes in multiple colors, tight tolerance up to ±0.01 mm for perfect switch alignment, one stop processing including CNC milling, drilling, surface treatment and laser engraving. Ideal for gaming keyboards, professional mechanical keyboards and custom layouts supporting 60%, 65%, 75% configurations with RGB light transmission, offering high durability, premium metallic feel and customizable color schemes for keyboard manufacturers seeking competitive pricing and superior quality components.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

You are very welcome to visit us among many suppliers

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

This custom OEM multicolor anodizing brass keyboard case plate CNC service transforms standard brass into stunning keyboard panels with eye-catching color finishes from a trusted China manufacturer. Precision CNC milling creates perfect switch mounting holes, logo areas and ergonomic contours, followed by advanced multicolor anodizing that delivers blues, golds, purples and gradients with uniform coverage and lasting durability. Designed for mechanical gaming keyboards and professional setups, these multicolor anodizing brass keyboard case plates ensure flawless Cherry/Gateron switch alignment while enhancing RGB lighting effects through translucent anodized layers.

The one-stop workflow handles everything from raw brass stock to finished anodized panels ready for keyboard assembly. Tight tolerance control (±0.01mm) guarantees flatness and hole precision across 60%, 65% and 75% layouts. Global keyboard manufacturers benefit from competitive pricing, rapid prototyping and scalable production of multicolor anodizing brass keyboard case plates that elevate product aesthetics and market positioning.

Precision CNC Milling for Perfect Mechanical Switch Alignment

Advanced CNC mills shape brass keyboard case plates with exact hole arrays matching industry-standard switch footprints. This multicolor anodizing brass keyboard case plate service maintains hole-to-hole spacing within 0.01mm, ensuring stable keycap mounting without wobble or misalignment common in lower-quality panels.

Multi-Layer Anodizing Process Creates Stunning Color Transitions

Specialized anodizing tanks apply base colors followed by selective masking for multi-tone effects on brass keyboard case plates. The multicolor anodizing brass keyboard service achieves vibrant gradients and sharp color boundaries that withstand daily typing abuse while preserving RGB light transmission for illuminated keyboards.

Durable Brass Construction with Premium Surface Hardness

Brass provides natural rigidity and acoustic resonance prized by mechanical keyboard enthusiasts. Post-anodizing hardness exceeds standard aluminum panels, making multicolor anodizing brass keyboard case plates resistant to scratches and wear in high-use gaming environments.

One-Stop Mechanical Keyboard Panel Production for Faster Market Launch

From CNC milling through multicolor anodizing and laser engraving, this service delivers complete brass keyboard case plates eliminating coordination between multiple vendors. Precision drilling creates cable routing channels and mounting holes, while surface preparation ensures flawless anodizing adhesion. The China manufacturer's integrated capabilities support rapid iteration from prototype 60% layouts to full production runs of 75% gaming keyboard panels with custom color schemes.

Quality inspection verifies panel flatness, hole accuracy and color uniformity using CMM, height gauges and roughness testers. Every multicolor anodizing brass keyboard case plate batch receives 100% final QC with documentation supporting manufacturer certification needs.

Integrated Laser Engraving for Custom Logos and Serial Numbers

Precision lasers etch legends, branding and unique identifiers into brass keyboard case plates before anodizing seals the markings permanently. This multicolor anodizing brass keyboard service supports complex patterns and fine text without compromising surface integrity.

RGB-Optimized Anodizing Layers Enhance Lighting Effects

Translucent anodizing formulas balance opacity and light transmission for stunning underglow and per-key RGB illumination. Mechanical keyboard manufacturers achieve premium visual effects through the multicolor anodizing brass keyboard case plate service's specialized finishing expertise.

Flexible Layout Support from Compact 60% to Full-Size Boards

CNC programming adapts to diverse keyboard architectures while maintaining dimensional accuracy across all mounting features. The service produces multicolor anodizing brass keyboard case plates for TKL, 75% and ergonomic split layouts with consistent quality.

Engineering Collaboration That Perfects Your Keyboard Panel Design

Experienced engineers review STEP, SolidWorks and DXF files to optimize switch spacing, reinforce high-stress areas and refine anodizing color transitions for multicolor anodizing brass keyboard case plates. Design consultations address RGB light paths, acoustic chambering and thermal dissipation specific to gaming keyboard requirements. Reverse engineering converts existing aluminum panels into superior brass versions with enhanced durability and aesthetics.

This technical partnership accelerates development of custom OEM multicolor anodizing brass keyboard service projects, minimizing costly revisions through early manufacturability validation.

Anodizing Color Simulation and Material Matching

Digital previews guide color selection ensuring multicolor anodizing brass keyboard case plates match brand identity across lighting conditions and viewing angles.

Switch Compatibility Verification Across Major Manufacturers

Panel templates confirm fitment for diverse mechanical switches before production, eliminating assembly surprises for multicolor anodizing brass keyboard service customers.

Acoustic and Thermal Design Optimization

Strategic milling creates resonance chambers and heat vents enhancing typing feel and component cooling in brass keyboard case plates.

Scalable Production Powering Mechanical Keyboard Brand Growth

Low MOQ enables keyboard startups to test multicolor anodizing brass keyboard case plate designs with single-unit prototypes, scaling seamlessly to thousands for seasonal launches. Multiple CNC centers with dedicated anodizing lines handle peak demands without sacrificing lead times. Transparent weekly updates with machining videos and color samples maintain global customer confidence throughout Shenzhen production.

Efficient logistics deliver delicate anodized panels worldwide in protective packaging preserving flawless finishes upon arrival.

Rapid Prototyping for New Keyboard Colorways

Samples ship within days for fit and appearance verification, accelerating multicolor anodizing brass keyboard service market testing.

High-Volume Capacity for Seasonal Keyboard Launches

Automated workflows sustain quality during production surges for popular multicolor anodizing brass keyboard case plate configurations.

Global Shipping from China's Keyboard Manufacturing Hub

Strategic location optimizes delivery timelines for keyboard manufacturers worldwide.

Market Applications Showcasing Brass Keyboard Panel Superiority

Multicolor anodizing brass keyboard case plates dominate enthusiast gaming keyboards where premium materials command price premiums. Professional workstations benefit from durable construction and elegant finishes, while custom keyboard builders appreciate personalization options. The service powers 60% minimalist boards to full-layout productivity keyboards across consumer and commercial segments.

Brass construction delivers unmatched typing acoustics and longevity justifying investment in multicolor anodizing brass keyboard service components.

Gaming Keyboards Demanding Visual Impact and Durability

Vibrant anodized finishes paired with RGB lighting create show-stopping multicolor anodizing brass keyboard case plates for competitive gaming.

Professional Keyboards Requiring Executive Presence

Subtle metallic finishes elevate corporate keyboard aesthetics through premium brass keyboard case plate construction.

Custom Keyboard Community Favorite Materials

Endless color combinations fuel enthusiast creativity with reliable multicolor anodizing brass keyboard service execution.

Competitive Pricing for Premium Keyboard Components

China manufacturing efficiency delivers luxury multicolor anodizing brass keyboard case plates at accessible volumes.

This comprehensive custom OEM multicolor anodizing brass keyboard case plate CNC service equips mechanical keyboard manufacturers with market-leading panels combining Chinese production efficiency, premium material quality and innovative finishing technology for superior brand positioning and customer satisfaction.