OEM Metal Fabricating Services Aluminum Stainless Steel CNC Milling Turning Part Precision Machining Service

Product Overview – CNC Machining Milling Turning Parts Service

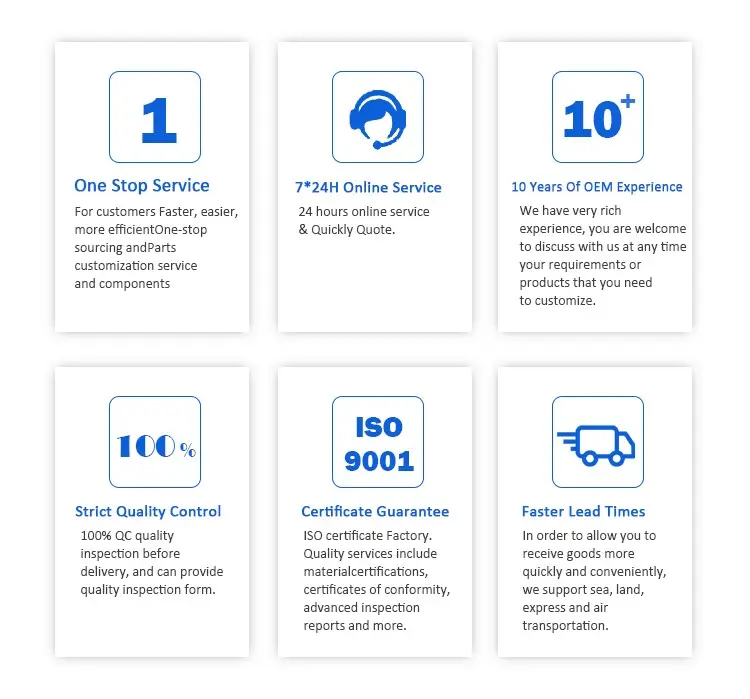

Shenzhen Huarui Century Technology Co., Ltd. provides professional OEM metal fabricating services that cover CNC milling, turning, and precision machining of aluminum, stainless steel, copper, titanium, and engineering plastics. With advanced production equipment and strict quality management, our company has become one of the leading suppliers in precision machining for industrial, automotive, and electronic applications.

Key Features:

High-Precision Machining Performance – We utilize high-speed CNC machines and coordinate measuring technology to ensure tight tolerance control, achieving accuracy up to ±0.005mm.

Comprehensive Material Capability – Our machining service supports aluminum, stainless steel, copper, titanium alloy, and various engineering plastics, meeting diverse application requirements.

Excellent Surface Quality – The processed parts feature smooth surfaces with a fine finish, suitable for direct assembly or as decorative precision components.

Customized OEM Solutions – We provide complete customization according to 2D drawings or 3D CAD files, offering flexibility for both prototypes and mass production.

Our CNC machining milling turning parts service ensures reliable product performance, stable structure, and consistent dimensional accuracy. Whether you require small-batch custom parts or large-scale OEM production, Huarui Century delivers high-quality components tailored to your needs.

Product Advantages

Precision CNC Milling and Turning with Tight Tolerance Control

Shenzhen Huarui Century Technology Co., Ltd. offers advanced CNC machining milling turning parts services designed for ultra-precision manufacturing. Our workshop is equipped with high-speed 3-axis, 4-axis, and 5-axis CNC machines capable of handling complex geometries with tolerances up to ±0.005mm. This precision ensures that every component meets the strictest dimensional and performance requirements, reducing assembly errors and improving overall product quality. The process stability and repeatability make it suitable for industries requiring critical accuracy, such as aerospace, robotics, and precision instruments.

Multiple Material Processing Capability

Our machining services cover a broad range of materials, including aluminum, stainless steel, copper, titanium alloy, and engineering plastics. Each material is selected based on strength, weight, corrosion resistance, and surface finish requirements. For example, aluminum components are ideal for lightweight designs with good thermal conductivity, while stainless steel parts provide high strength and corrosion resistance. Copper and brass are often used for conductive or decorative parts, and engineering plastics allow for electrical insulation and flexibility. With rich experience in different material behaviors, our engineers optimize cutting parameters for the best machining efficiency and surface finish.

Superior Surface Finish and Ready-to-Assemble Quality

The CNC machining milling turning parts service we provide guarantees exceptional surface smoothness. We employ advanced cutting tools and optimized feed rates to achieve mirror-like finishes. After machining, parts can undergo optional surface treatments including anodizing, sandblasting, polishing, or plating, depending on client requirements. The high surface quality allows components to be directly assembled without additional processing, saving time and cost in downstream manufacturing. For decorative components or visible mechanical parts, our finish quality meets even the most demanding aesthetic standards.

Integrated Production and Inspection System

From prototype development to mass production, our process is fully controlled and traceable. Each part is inspected using CMMs (Coordinate Measuring Machines), projectors, and surface roughness testers to ensure dimensional conformity. Real-time quality tracking during production guarantees that all CNC machined parts comply with ISO9001 and RoHS standards. Huarui Century’s integrated quality system minimizes defects, shortens production lead time, and delivers consistent reliability across every order.

Flexible OEM & ODM Support

Whether customers need one-time prototype machining or long-term OEM cooperation, we provide tailored services. Our engineering team assists in DFM (Design for Manufacturability) evaluation, process optimization, and material selection. We can also support secondary processes like welding, assembly, and surface marking to provide ready-to-use products. The entire production chain—from quotation to shipment—is managed under one system, ensuring seamless communication and efficient delivery.

Custom Cooperation Process

Inquiry and Design Confirmation

Customers can send 2D/3D drawings or physical samples. Our engineers evaluate technical requirements, tolerances, and materials to provide a detailed quotation and production plan.

DFM Analysis and Sample Fabrication

Before mass production, we conduct Design for Manufacturability (DFM) analysis to ensure feasibility. A sample or prototype is then produced for client approval.

Mass Production and Quality Control

After confirmation, production begins under strict process control. Each batch undergoes first article inspection and continuous in-process checks to maintain precision and stability.

Surface Treatment and Final Inspection

Upon machining completion, parts receive the required surface treatment such as anodizing, powder coating, or polishing. A final inspection ensures that all parameters meet the specifications before shipment.

Packaging and Delivery

Components are packed securely with protective materials to avoid damage during transport. International logistics services ensure safe and timely delivery to any destination worldwide.

Frequently Asked Questions (FAQ)

Q1: What is the maximum tolerance your CNC machining can achieve?

Our CNC machining milling turning parts service achieves a dimensional tolerance as tight as ±0.005mm, depending on material type and component geometry.

Q2: Which materials can you machine?

We can process a wide range of materials including aluminum, stainless steel, copper, brass, titanium, and engineering plastics such as POM, PTFE, and nylon.

Q3: Can you handle both small and large production volumes?

Yes, we support both prototype machining for new designs and mass production for long-term supply. Flexible batch management ensures cost-effectiveness for all order sizes.

Q4: What surface finishes are available?

We offer anodizing, electroplating, sandblasting, polishing, powder coating, and laser engraving, among others. These processes enhance corrosion resistance and improve appearance.

Q5: How do you ensure quality consistency?

All manufacturing processes are carried out under ISO9001 certification. Our inspection system includes 100% dimensional verification before shipment.

Q6: What is your typical lead time?

Lead time varies according to part complexity and quantity—usually 7–15 days for samples and 20–30 days for bulk production.

Contact Us

Shenzhen Huarui Century Technology Co., Ltd. is committed to delivering excellence in CNC machining milling turning parts service. With cutting-edge equipment, experienced engineers, and strict quality assurance, we provide precise and durable components that exceed client expectations.

Send us your inquiry today for a free consultation and quotation. Our professional team will help you design and produce the perfect CNC machined aluminum or stainless steel parts for your project.

Experience true precision manufacturing with Huarui Century’s OEM metal fabricating services — where accuracy meets efficiency.