Process introduction

Craft name |

Die casting parts service |

Mold Material |

Aluminum,SKD61ï¼45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Material |

Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . Zinc: ZA3#, ZA5#, ZA8# or customized . Magnesium: AZ91D, AM60B or customized . |

Surface Treatment |

Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Deep Processing |

CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

Application |

furnitureï¼Industry fittings and Construction and Decorationï¼etc. |

You are very welcome to visit us among many suppliers

We have very strict quality control process

Q1ï¼What is the specific production process? |

Die designingâDie makingâSmelting&alloyingâQCâDie castingâremove burrsâQCâSurface treatmentâQCâPackingâQCâShippingâAfter Sale Service. |

Q2: How soon can I get samples? |

Depending on your specific project, it usually takes 10 to 20 days. |

Q4:Can you make machining parts based on our samples? |

Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Product Overview

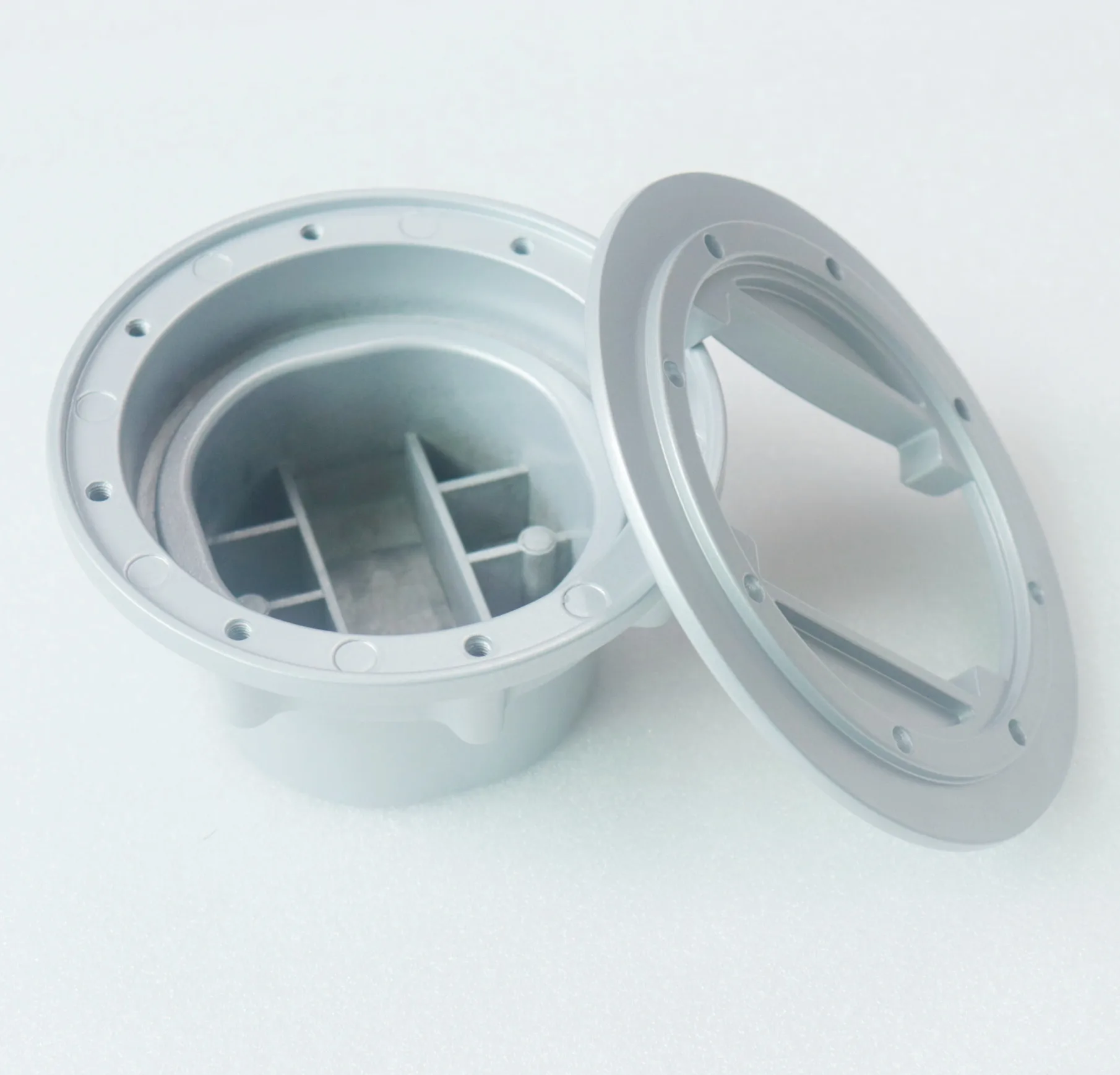

The China Die Cast Suppliers Precision Customization Aluminum Die Casting Round Metal Lampshade represents the culmination of advanced metal casting technology combined with precise design engineering. Manufactured by Shenzhen Huarui Century Technology Co., Ltd., this product integrates high-performance aluminum alloys with cutting-edge die casting processes to deliver a consistent and high-quality lampshade solution for industrial and decorative applications.

-

High Precision Design: Each lampshade is engineered to exacting tolerances, ensuring uniformity and seamless integration into lighting fixtures. Utilizing customer-provided 3D designs, the product accommodates complex geometries while maintaining dimensional stability.

-

Durable Material Composition: The lampshade is primarily constructed from premium aluminum alloys, delivering superior mechanical strength, corrosion resistance, and excellent thermal conductivity. Optional surface treatments, including anodizing, polishing, and electroplating, enhance durability and aesthetic appeal.

-

Functional Performance: Lightweight yet rigid, the die-cast construction provides a sturdy structure capable of withstanding mechanical stresses during installation and long-term operation. The surface finish achieves Ra1.6μm, ensuring smoothness for both functional and decorative purposes.

-

Customization Flexibility: Shenzhen Huarui offers tailored manufacturing services, enabling the production of round lampshades with specific diameters, wall thicknesses, surface textures, and branding features such as engraved logos or patterns.

-

Industrial Application: Suitable for architectural lighting, industrial fixtures, and designer lamps, this product meets the rigorous demands of both commercial and residential lighting solutions.

Product Advantages

High Production Efficiency and Automation

Shenzhen Huarui's die casting process leverages fully automated production lines, enabling rapid high-volume manufacturing. Automated molten metal injection and precision mold handling reduce cycle times while maintaining uniformity across thousands of units. This efficiency ensures stable pricing and reliable supply, especially for large-scale projects requiring consistent quality.

Exceptional Dimensional Accuracy

Each lampshade is produced under stringent quality control measures, resulting in precise adherence to design specifications. The die casting process achieves tight tolerances (VDG P690 D2) and maintains consistency across multiple production batches. This accuracy minimizes post-processing requirements, saving time and cost while ensuring flawless integration into lighting assemblies.

Versatile Thin-Wall and Complex Feature Production

The round metal lampshade design benefits from the ability to produce thin-walled structures (aluminum down to 1.2mm) without compromising strength. Integrated features such as ribs, grooves, or threaded inserts can be cast in a single process, eliminating the need for secondary machining. This capability enhances both functional performance and aesthetic complexity, providing superior design flexibility for architects and designers.

Production Process

The manufacturing of the aluminum die casting round lampshade follows a structured and highly controlled workflow:

-

Mold Design and Fabrication: High-precision steel molds are engineered using advanced simulation software to optimize metal flow, solidification, and minimize defects. Complex textures, branding elements, and structural features are incorporated at this stage.

-

Die Casting: Molten aluminum is injected into the mold under high pressure, ensuring complete filling and minimal porosity. Rapid cooling produces a dense, fine-grained internal structure that enhances mechanical properties.

-

Post-Casting Operations: Once cooled, lampshades undergo deburring, surface finishing, and optional machining to achieve the desired final appearance. Treatments such as polishing, anodizing, or plating provide additional corrosion resistance and aesthetic refinement.

-

Quality Assurance: Each component is subjected to rigorous inspection, including dimensional verification, X-ray analysis, and CMM measurements to guarantee compliance with design specifications. Only products passing 100% inspection proceed to packaging.

-

Packaging and Dispatch: Finished lampshades are carefully packaged to prevent damage during transportation. Multiple layers of protective materials ensure safe delivery to customers or distributors.

Product Parameters Table

| Parameter | Specification |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HUARUI |

| Model Number | HR |

| Product Name | Die Casting Part, Sand Casting, Investment Casting |

| Process | Casting, Deburring, Drilling, Threading |

| Certification | ISO9001 |

| Service | Customized OEM |

| Size | Customer's 3D Drawing |

| Surface Treatment | Customers' Demand |

| Tolerance | Customer's Drawing Request |

| Standard | Client Specification |

| Color | Customized Color |

| Quality Control | Strictly 100% Inspection |

| Materials | Aluminum alloys (ADC12, A380, 6063), Stainless Steel, Cast Iron |

| Surface Finish | Ra1.6–Ra3.2 |

| Max Size | ≤1200mm x 800mm x 400mm |

| Weight Range | 0.1–120 kg |

| Application | Industrial, Machinery, Construction, Decorative Lighting, Auto Parts |

| Inspection | Chemical analysis, Magnetic powder, Cleanliness, X-Ray, CMM |

Information Access for Customized Specifications

Engineers, project planners, and industrial designers seeking detailed technical specifications, material compatibility, and customization options often engage with Shenzhen Huarui’s technical team to explore tailored solutions. Comprehensive documentation, including 3D modeling parameters, alloy recommendations, and surface treatment options, is made available to facilitate informed design and procurement decisions. This approach allows potential partners to evaluate production feasibility, compare design alternatives, and understand manufacturing constraints before initiating formal procurement discussions.

Frequently Asked Questions (FAQ)

Q1: What materials are suitable for these die-cast lampshades?

A1: Aluminum alloys (ADC12, A380, 6063) are standard, providing excellent strength, corrosion resistance, and thermal performance. Optional materials include stainless steel and cast iron depending on functional requirements.

Q2: Can the lampshades include integrated threading or mounting features?

A2: Yes, threads, ribs, grooves, and inserts can be incorporated during the die casting process, eliminating the need for secondary machining.

Q3: What surface finishes are available?

A3: Standard options include polishing, anodizing, plating, powder coating, and custom textures. Ra1.6μm surface smoothness can be achieved for aesthetic and functional purposes.

Q4: How precise are the dimensions?

A4: The die casting process achieves tight tolerances as per VDG P690 D2 standards, ensuring high repeatability across large production volumes.

Q5: What is the maximum size and weight of a lampshade that can be produced?

A5: Maximum dimensions are 1200mm x 800mm x 400mm, with individual weights ranging from 0.1 kg to 120 kg, depending on design specifications.

Q6: Are custom designs supported?

A6: Yes, customer-provided 3D models are fully supported, allowing precision casting of unique round lampshade designs, including logos, textures, or specialized structural elements.