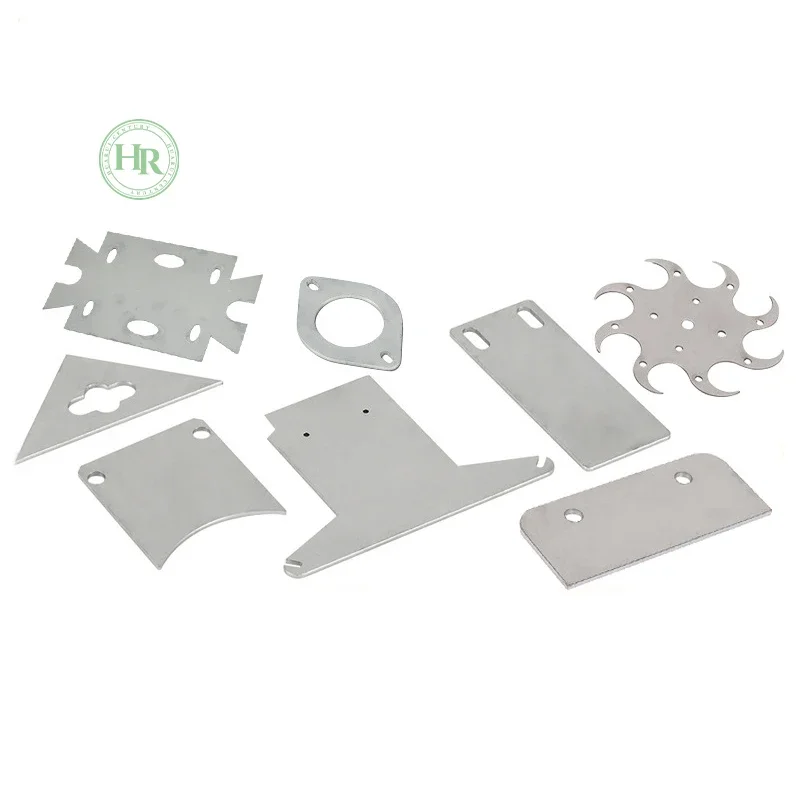

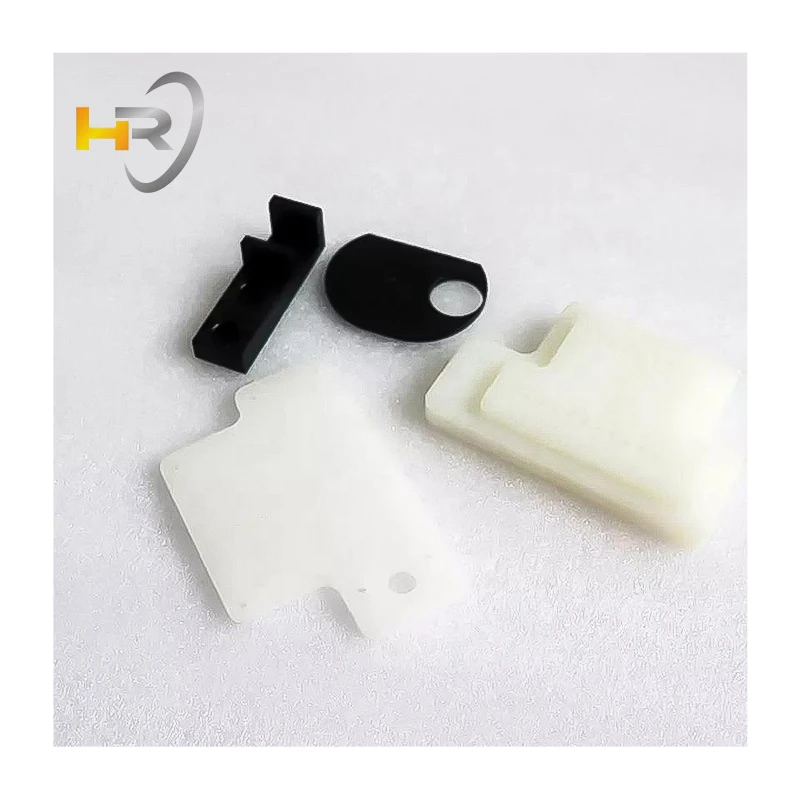

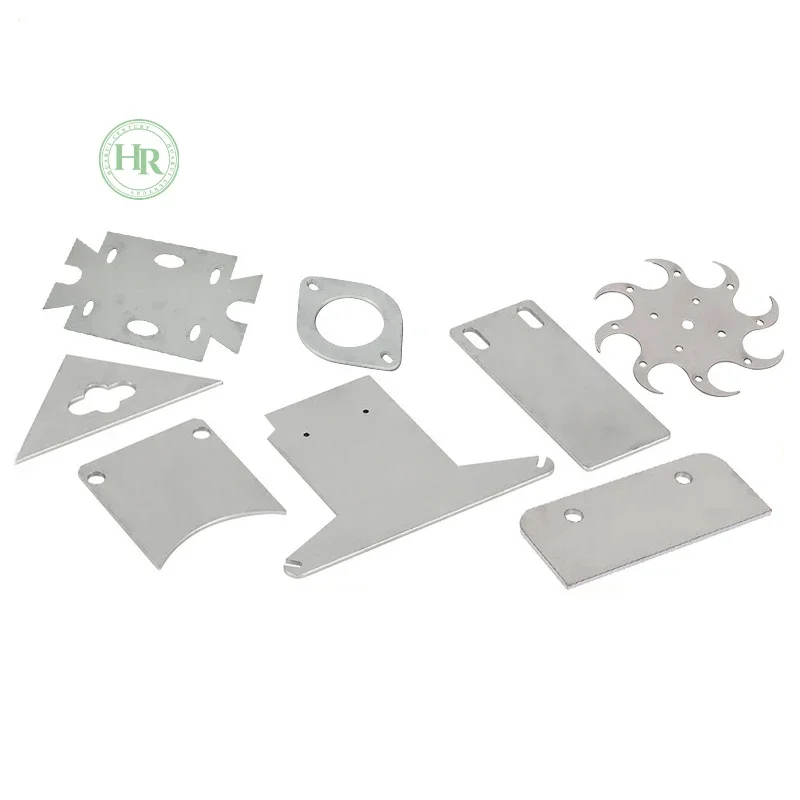

Custom Sheet Metal Part Fabrication Aluminum Stainless Steel bending welding metal stamping service laser cutting parts

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Name |

custom manufacturing sheet metal fabrication parts service |

Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Processing |

Stamping ,Sheet metal fabrication |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Our Advantages |

1.) 24 hours online service & Quickly Quote/Delivery. 2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) To provide production design, production and technical service, mould development and processing, etc |

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. specializes in Custom Sheet Metal Part Fabrication Aluminum Stainless Steel bending welding metal stamping service laser cutting parts, offering precision-engineered component solutions for a wide range of industrial needs. Our advanced fabrication capabilities integrate laser cutting, CNC bending, high-strength welding, and progressive metal stamping to ensure superior performance and long-term reliability.

Our machining systems are designed to maintain precise dimensional control and minimal material distortion, making them ideal for complex structural designs and assemblies. We support multiple materials including stainless steel, aluminum alloys, galvanized steel, and copper-based metals. With a professional engineering team and highly automated production lines, we deliver consistent quality from rapid prototyping to large-scale batch production.

Key product performance characteristics:

-

High structural rigidity through optimized forming techniques

-

Smooth, uniform edges suitable for assembly and surface treatment

-

Excellent corrosion resistance when using stainless steel and coated materials

-

Superior durability for components used in challenging operating conditions

-

Flexible customization for varied geometries, hole layouts, and mounting structures

These Custom Sheet Metal Part Fabrication Aluminum Stainless Steel bending welding metal stamping service laser cutting parts are widely applied in the automotive industry, telecommunications equipment, consumer electronics housings, renewable energy systems, medical equipment frames, industrial automation machinery, and beyond.

Main Advantages

High Precision Cutting with Stable Consistency

Our laser cutting technology maintains a maximum tolerance of ±0.1 mm, ensuring extremely accurate and repeatable outcomes for every production cycle. The laser process uses digital power adjustment to achieve precise kerf widths and reliable part interfaces. This is especially valuable when producing parts requiring exact alignment during final assembly, such as connectors, enclosures, and precision supports.

Minimal Heat-Affected Zones for Enhanced Structural Integrity

With non-contact processing, the cutting beam induces very low mechanical stress. Heat deformation is significantly reduced, which means the original material strength is maintained even on thin or lightweight metals. The cut edges are typically smooth and burr-free, reducing the need for additional finishing work and lowering overall production costs. This advantage is critical for stainless steel and aluminum components that demand clean surfaces to ensure perfect performance after welding or coating.

Efficient Production for Multi-Variety Orders

Thanks to the high automation level of CNC laser cutting and robotic forming lines, production can be quickly adapted for different product specifications. Nesting optimization improves material utilization and reduces waste. We support continuous operation with real-time monitoring, making batch manufacturing faster and cost-effective while also accommodating frequent design adjustments during development cycles. This flexible workflow enables fast delivery without compromising precision.

Application Scenarios

Our Custom Sheet Metal Part Fabrication Aluminum Stainless Steel bending welding metal stamping service laser cutting parts demonstrate versatility in the following sectors:

Industrial Equipment and Machinery

-

Machine frames, guards, mounting plates, and structural brackets

-

Reliable components for heavy-duty usage with strong mechanical endurance

Electric and Communication Systems

-

Cabinets, chassis, and heat-ventilation panels

-

Complex cut-outs for connectors and advanced wiring layouts

Automotive and Transportation

-

Functional metal brackets, reinforcement elements, interior hardware

-

Lightweight material options support improved fuel efficiency

Consumer Electronics and Smart Devices

-

Precision metal housings with superior finishing quality

-

High-volume production supported with consistent uniformity

Our manufacturing excellence ensures that products remain durable under repeated stress, frequent use, and challenging environments.

Request a Quote

We invite global buyers, project contractors, and OEM/ODM manufacturers to contact us for customized sheet metal fabrication solutions. To provide you with the most precise quotation, please include:

-

Drawings in STEP, STP, IGES, DWG, DXF, or PDF

-

Required materials, thickness, and finishing

-

Intended application and special functional requirements

-

Target quantity and expected delivery timeline

Our engineering experts will evaluate and respond with detailed pricing and technical recommendations. Shenzhen Huarui Century Technology Co., Ltd. guarantees reliable support throughout the workflow, from concept validation to final delivery.

FAQ

Q1: Do you accept small orders or prototypes?

Yes, we support small-batch manufacturing and single-piece proofing for design testing.

Q2: Which industries benefit most from your fabrication services?

Automotive, energy systems, medical devices, industrial automation, telecommunications, and consumer electronics.

Q3: What welding technologies do you offer?

MIG, TIG, spot welding, and robotic welding solutions tailored to metal type and thickness.

Q4: Can you provide surface treatment?

Yes, we offer powder coating, anodizing, plating, brushed finishing, and more upon request.

Q5: How do you assure quality during production?

Each part undergoes dimensional inspection, welding analysis, and material verification. Full documentation is provided for traceability.

Q6: What is your typical lead time?

Lead time varies by project complexity but generally ranges from 7–25 working days with expedited options available.