casting services foundry custom 304/316 SS 17-4 PH stainless steel iron metal precision casting part lost wax investment casting

Achieve unparalleled complexity and accuracy with our professional investment casting (lost wax casting) services. We specialize in manufacturing high-integrity precision components from premium stainless steels including 304, 316, and 17-4 PH, ideal for applications demanding exceptional strength, corrosion resistance, and dimensional stability. Our process captures intricate geometries and fine details, delivering near-net-shape parts with excellent surface finish. Supported by ISO 9001 certification and full compliance with RoHS/REACH, we are a trusted manufacturer offering end-to-end custom solutions from prototype to production for medical, aerospace, industrial, and high-end decorative sectors.

Processing technology |

Investment casting parts |

Mold Material |

Aluminum,SKD61,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Material |

Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . Zinc: ZA3#, ZA5#, ZA8# or customized . Magnesium: AZ91D, AM60B or customized . |

Surface Treatment |

Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Certificate |

iso9001, iso14001, REACH, ROHS |

Application |

furniture,Industry fittings and Construction and Decoration,etc. |

Huarui

Is a trusted providers of casting services, with a focus on custom 304/316 SS, 17-4 PH stainless steel, iron, and other metal precision casting parts using the lost wax investment casting method. Our teams of skilled professionals has the expertise necessary to create high-quality, precised parts to meet your specific needs.

We realize that no two projects would be the same, which is why you can expects a variety of casting services to suits your requirements which can be unique. Our custom casting options allows one to specify the exact measurements, materials, and finishes for the parts, ensuring that you get the fit is perfect times.

We use only the quality materials which are highest in our castings services, including 304/316 SS, 17-4 PH stainless, and iron. These materials are known for their durability, corrosion resistance, and powers, making them perfect for a range is wide of.

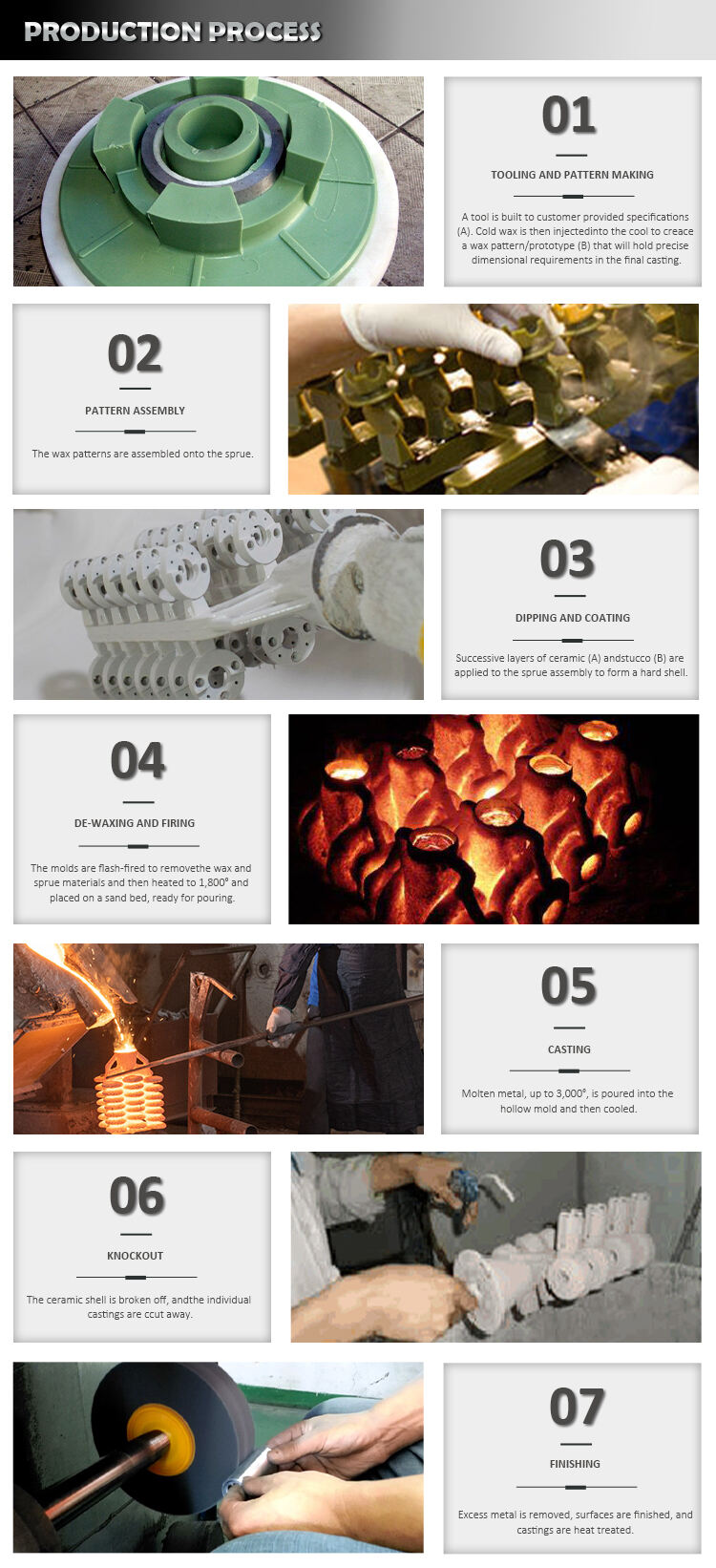

Process begins aided by the lost wax investment casting method, which involves creating a wax is accurate of the component you needs. This model will be coated in heated and ceramics to create a mold. Once the mold is made, steel is poured in and allowed to cool, leading to a perfect replica of the model is original.

Group of skilled professionals takes cared is excellent ensure that every part we produce meets our strict quality standards. We use advanced testing equipment and techniques to verify that each components fulfills your exact specifications, ensuring that you will get the finest quality that can be done time.

Whether you need custom 304/316 SS, 17-4 PH stainless steel, or iron castings services, Huarui is the name you can trust. Our team of skilled professionals and commitment to quality ensures that you get the best possible product with every orders. So why wait? Contact us today to learn more about our castings services and how we can meet your specific needs.

Redefining Complexity: Your Partner for Precision Investment Casting

In industries where component failure is not an option, the pursuit of perfection in metal parts is relentless. For engineers and designers pushing the boundaries of what's possible, conventional manufacturing methods often hit a wall when faced with intricate geometries, internal channels, or ultra-thin walls. This is the precise challenge that our investment casting service is engineered to solve. We are not merely a foundry; we are a specialized partner dedicated to transforming your most complex and demanding designs into reality with unmatched fidelity. Our focus on premium stainless steels and the lost wax investment casting process positions us as the ideal source for mission-critical components across the world's most advanced industries.

The Art and Science of Lost Wax Investment Casting

What sets investment casting apart in the world of metal fabrication? It is a process defined by its ability to achieve what others cannot. Beginning with a precise wax pattern of your part, we build a ceramic shell mold around it. Once the wax is melted away, molten metal is poured into the resulting cavity. This method grants extraordinary design freedom, allowing for the production of parts with exceptional dimensional accuracy, complex internal and external features, and a superior surface finish that often requires minimal post-casting machining. Compared to sand casting or forging, investment casting produces near-net-shape components with tighter tolerances and finer detail. This makes it the undisputed choice for creating strong, lightweight, and geometrically sophisticated parts, ensuring your vision is realized without compromise.

Material Excellence: Engineered for Performance with Stainless Steel

The capabilities of investment casting are fully realized only when paired with the right material. We specialize in a range of high-performance stainless steels, each selected for specific operational demands.

304 & 316 Stainless Steel:

These austenitic grades are the cornerstone of corrosion resistance. Type 304 offers excellent general-purpose resistance, while Type 316, with its added molybdenum, provides superior protection against chlorides and acidic environments, making it ideal for marine, chemical processing, and medical applications. Our investment casting process preserves their innate durability, producing parts that withstand harsh conditions while maintaining structural integrity.

17-4 PH Stainless Steel:

When your application requires a combination of high strength and good corrosion resistance, 17-4 PH (Precipitation Hardening) stainless steel is the premier choice. This martensitic grade can be heat-treated to achieve impressive tensile strength and hardness, rivaling many alloy steels, while maintaining significantly better corrosion resistance. It is exceptionally suited for aerospace components, high-stress industrial fittings, and critical machinery parts where both durability and performance are paramount.

Our expertise ensures that the superior material properties of these stainless steels are fully leveraged in every investment casting we produce.

From Digital Blueprint to Physical Masterpiece: Our Integrated Service

We bridge the gap between your design and a flawless finished component. Our service begins with your digital design, and we accept all major 2D and 3D file formats, including STEP, IGES, and Solidworks. Our engineering team provides expert design for manufacturability (DFM) feedback, optimizing your part for the investment casting process to enhance quality and optimize cost. We then move to precision pattern and mold creation, followed by controlled casting in our dedicated foundry.

The journey continues with our comprehensive in-house capabilities. We offer a full spectrum of surface treatments, from standard mill finish and uniform sand blasting to precision polishing and advanced coatings, ensuring your parts meet exact aesthetic and functional specifications. This vertical integration—from mold-making to final finishing—guarantees strict quality control at every stage, reduces lead times, and provides you with a single point of accountability for your entire project.

A Commitment to Quality You Can Measure and Trust

Every investment casting part we deliver is built on a foundation of rigorous quality assurance. Our commitment is formalized through our ISO 9001-certified quality management system, which governs every procedure from material sourcing to final inspection. We adhere to international environmental and safety standards, including RoHS and REACH compliance, ensuring our components are suitable for global markets. Our quality control process includes dimensional verification using advanced measuring tools, material chemistry analysis, and visual inspections to guarantee that each stainless steel investment casting meets not only your specifications but also the highest industry benchmarks for precision and reliability.

Applications Where Precision is Paramount: Transforming Industries

The components manufactured through our investment casting service are engineered to excel in the most demanding environments. In the medical and dental fields, we produce biocompatible, complex instrument parts and device housings that meet stringent sterilization and precision requirements. The aerospace and defense sectors rely on our ability to create strong, lightweight, and reliable components for critical systems. For industrial machinery and automation, we supply durable, wear-resistant parts like complex valves, pump impellers, and sensor housings that ensure operational longevity.

Beyond heavy industry, our craftsmanship serves the high-end consumer and architectural markets, producing intricate decorative hardware, luxury furniture components, and detailed architectural metalwork where beauty and precision intersect. This wide applicability demonstrates how our investment casting service provides tailored solutions that drive innovation and performance, regardless of the sector.

Your Next Step Toward Flawless Components

Initiating a project with us is a collaborative and transparent process. We begin by understanding your specific requirements, reviewing your designs, and providing a detailed, competitive quotation. We are committed to clear communication throughout the production cycle, keeping you informed of progress.

As an experienced manufacturer with deep expertise in stainless steel investment casting, we are dedicated to building lasting partnerships based on trust, quality, and consistent delivery. We invite you to experience the difference that a focused precision casting partner can make. Contact us today to discuss your project requirements for 304, 316, or 17-4 PH stainless steel investment castings. Submit your drawings for a complimentary feasibility review and quote, and let us show you how we can bring your most complex designs to life with uncompromising quality.