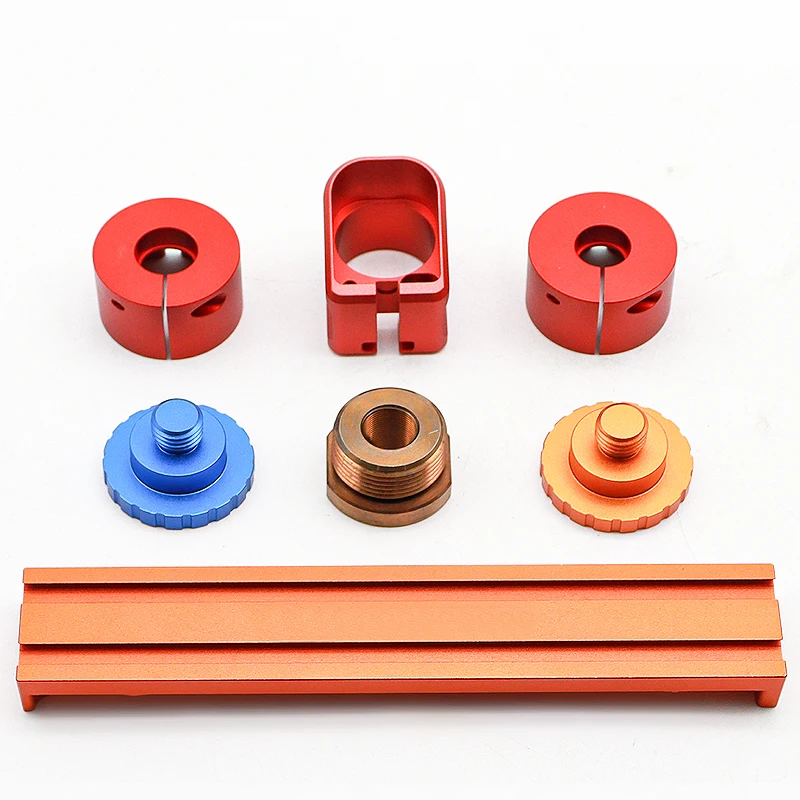

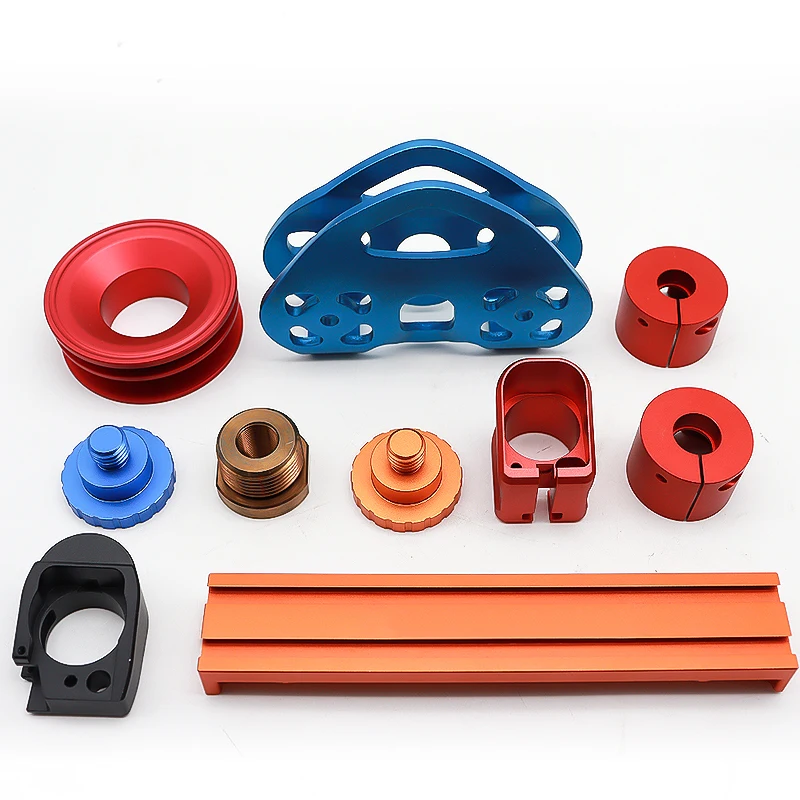

OEM Manufacturer Customization Cnc Machining stainless steel Cnc turning Parts Cnc Machining Bicycle Parts

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Product Overview

Precision-Crafted CNC Components for High-Performance Bicycles and Industrial Use

Shenzhen Huarui Century Technology Co., Ltd. is a professional OEM manufacturer specializing in CNC machining stainless steel turning parts and customized CNC machining bicycle components. With comprehensive capabilities in CNC milling, CNC turning, broaching, drilling, wire EDM, rapid prototyping, and micro machining, we provide accurate, repeatable, and cost-effective machining solutions to global customers.

Our CNC machining bicycle parts are designed for enhanced safety, durable performance, and lightweight design optimization. From axle components and threaded connectors to brake system parts and shock-absorbing structures, every unit is manufactured under strict dimensional tolerance control to achieve smooth installation and reliable functionality.

Key Performance Features

• Multi-axis CNC machining enabling complex geometry and tight tolerances

• High strength and precision to support high-speed and rugged cycling conditions

• Compatible with both standard and customized bicycle structures

• Reliability tested for fatigue resistance in long-term outdoor environments

• Surface textures and treatments available to improve corrosion resistance and visual appeal

• Fully customizable size, structure, and branding for OEM partners

Our engineering experts work closely with customers to optimize product performance, weight reduction, assembly efficiency, and product lifecycle, making us a long-term trusted supplier for bicycle manufacturers, aftermarket equipment brands, and industrial sectors.

Core Product Advantages

1. High Wear Resistance and Excellent Fatigue Strength

Stainless steel CNC turning parts used in bicycles must withstand continuous rotational friction, repeated impact loading, and variable stress environments. Our machining methods optimize material integrity and fatigue performance, enabling:

• Long service life in critical stress-bearing locations such as hubs, shafts, and fasteners

• Stability under mountain biking, racing impact, and off-road vibrations

• Strong deformation resistance during high-torque pedaling and braking forces

Combined with our advanced inspection process, we ensure every part maintains reliable mechanical properties in real riding conditions.

2. Superior Thermal and Oxidation Resistance

Outdoor cycling exposes components to sun exposure, muddy roads, coastal salt environments, and sudden temperature changes. Our stainless steel materials feature:

• Anti-oxidation surface layers that prevent rusting and discoloration

• Ability to remain stable in both hot climates and winter conditions

• Enhanced durability through optional passivation treatment

This guarantees product longevity with minimal maintenance, ideal for bicycles used in harsh weather or competitive sports.

3. Multi-Surface Finishing and Branding Flexibility

To support both functional requirements and premium aesthetics, stainless steel CNC parts can be finished through:

• Mirror polishing or brushed processing for premium bicycles

• Laser marking for custom logos, indexing scales, or safety labeling

• PVD coatings for color customization and enhanced abrasion resistance

This allows bicycle brands to enhance recognition and product differentiation, while improving performance such as friction control and corrosion protection.

Customization Process

End-to-End OEM Manufacturing Support

We offer a flexible customization workflow designed for bicycle brands and industrial buyers:

• Requirement Consultation & Technical Review

Customers share 2D/3D drawings or samples. Our engineers evaluate assembly conditions, stress points, material optimization, and DFM enhancements.

• Precision Modeling & CNC Programming

We create tool paths for stable precision machining, reduce tool wear, and improve cycle time efficiency.

• Material Selection & Quality Verification

Raw materials sourced from certified suppliers. Stainless steel grades including 304, 316, 303, 17-4PH, etc., depending on structural demand and corrosion conditions.

• Prototype Validation & Performance Testing

Trial samples produced for fit-up analysis, cycling load tests, and quality verification before large-scale production.

• Batch Production & Full Inspection System

Automated machining, robust clamping solutions, and CMM inspection ensure consistency for every unit.

• Packaging & Global Logistics

Scratch-free packaging and international delivery enable smooth import processes for B2B buyers.

Our workflow ensures every CNC machining bicycle part aligns with brand positioning and market performance requirements.

Technical Specifications

| Item | Description |

|---|---|

| Product Name | CNC Machining Stainless Steel CNC Turning Parts / CNC Machining Bicycle Components |

| Machining Type | CNC Milling, CNC Turning, Broaching, Laser Machining, Wire EDM, Drilling |

| Material Options | Stainless Steel, Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals |

| Size | Customized |

| Surface Finish | Brushing, Polishing, Sandblasting, Coating, Passivation, PVD, etc. |

| Tolerances | As per customer drawing request |

| Inspection | 100% Quality Check |

| OEM/ODM | Accepted |

| Application | Bicycles, Industrial Mechanisms, Fastening Systems, Structural Support Components |

| Brand Name | HUARUI |

| Place of Origin | Guangdong, China |

| Micro Machining Capability | Yes |

| Production Order Type | Prototype / Small Batch / Mass Production |

Request a Quote

We are ready to support your product development and supply chain stability.

Send your drawing files (STEP, IGS, STP, DWG, PDF, etc.) and receive:

• Fast quotation within 12 hours

• Free engineering suggestions for cost reduction

• Short lead times and stable mass production capability

• Global shipping with secure packaging

Submit your inquiry now to build reliable CNC bicycle components with a certified OEM manufacturer.

Frequently Asked Questions (FAQ)

Q1: Can you develop new bicycle components based on our concept?

Yes. We provide complete OEM development support including engineering design review and optimization.

Q2: Are surface coatings customizable?

Yes. We offer PVD color coating, anodizing for aluminum parts, and various polishing grades.

Q3: What is the minimum order quantity?

Flexible MOQ. We support prototyping and small orders for brand testing.

Q4: How do you ensure product quality?

100% inspection with CMM, thread gauges, hardness testing, and visual checks.

Q5: Do you accept mixed metal production orders?

Yes. You may combine stainless steel bicycle parts with aluminum and brass parts in the same purchase order.