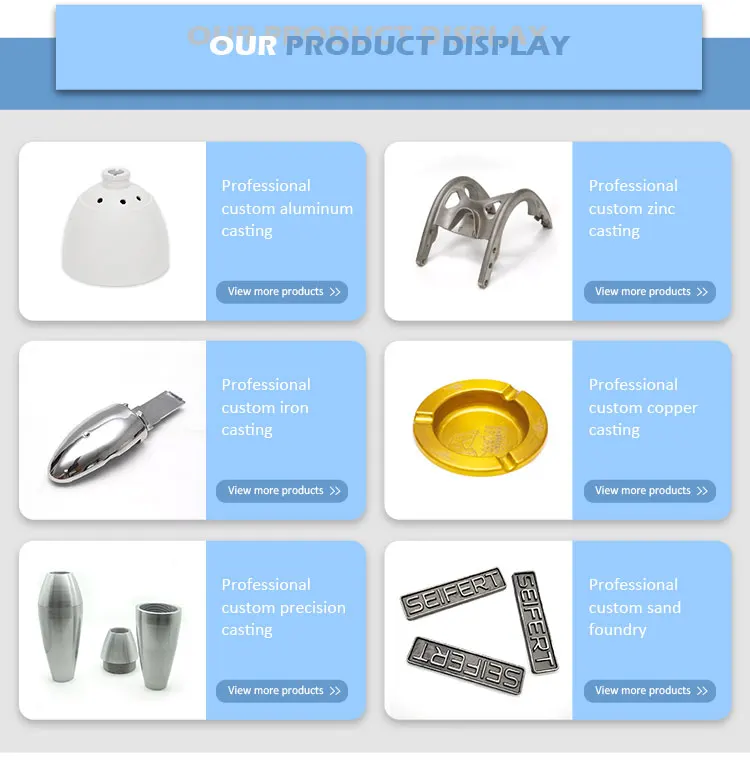

Aluminum Alloy Die Casting Spare Parts Furniture Industrial Fittings

Unlock high-volume production efficiency with our professional aluminum die casting services. We specialize in manufacturing custom, high-precision aluminum alloy parts (including ADC12, A380, A356) through advanced high-pressure die casting technology. Supported by comprehensive in-house capabilities from mold making using H13/718 steels to CNC machining and surface finishing, we offer a true one-stop solution. Ideal for demanding applications in furniture hardware, industrial fittings, and architectural decoration, we ensure rapid prototyping (samples in days), consistent quality, and reliable supply for your OEM or ODM projects.

Process introduction

Craft name |

Die casting parts service |

Mold Material |

Aluminum,SKD61,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Material |

Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . Zinc: ZA3#, ZA5#, ZA8# or customized . Magnesium: AZ91D, AM60B or customized . |

Surface Treatment |

Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Deep Processing |

CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

Application |

furniture,Industry fittings and Construction and Decoration,etc. |

Unlock Efficiency & Precision: Your Premier Aluminum Die Casting Solution

In the world of manufacturing, where volume, consistency, and detail are paramount, aluminum die casting stands as a cornerstone technology. As a specialized manufacturer with a decade of expertise, we provide more than just a service; we deliver a comprehensive aluminum die casting partnership. Our process is engineered for those who require complex, high-strength, and dimensionally stable components for sectors like furniture, industrial fittings, and construction. We transform your designs into reality, leveraging high-pressure injection to produce superior aluminum die casting parts with excellent surface finish and intricate details, ready for assembly or further finishing.

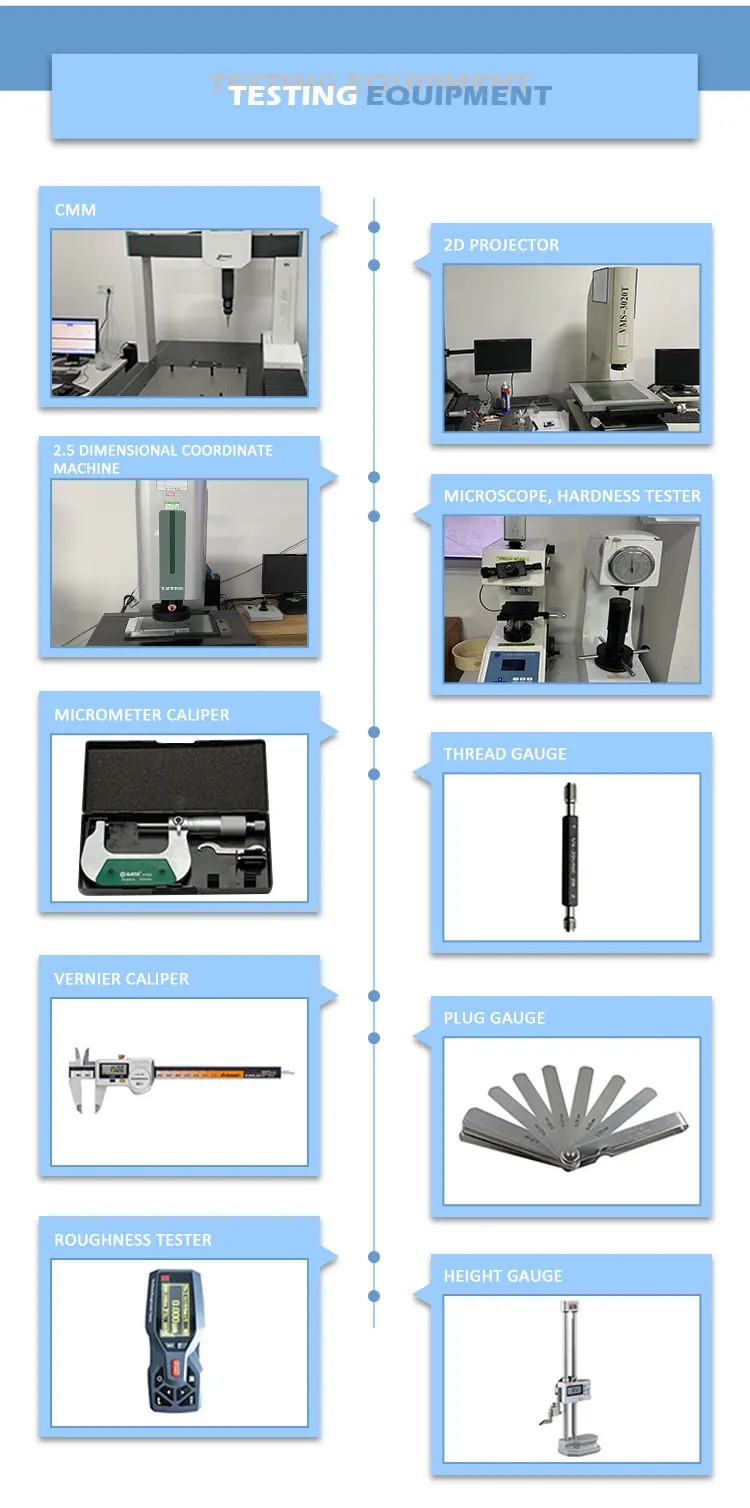

The Engine of Quality: Our Advanced Die Casting Process Unveiled

At the heart of our operation is the die casting process, a sophisticated method where molten aluminum alloy is injected under high pressure into a precision steel mold. This technique is the key to achieving what matters most for volume production: exceptional repeatability, minimal post-processing, and significant cost-effectiveness per part. Unlike other methods, high-pressure aluminum die casting allows for the creation of thin-walled yet robust components with remarkable geometric complexity, making it the ideal choice for durable hardware and structural fittings. Our focus is on optimizing every cycle—from mold temperature to injection speed—to ensure each custom aluminum die casting part meets stringent specifications for density and integrity.

Beyond the Cast: A Symphony of Materials and Finishes

The foundation of a great die casting part is the material. We offer a wide spectrum of aluminum alloys to match your functional needs. Choose ADC12 for excellent fluidity and cost-effectiveness in complex shapes, A380 for a superior strength-to-weight ratio, or A356 for enhanced mechanical properties through heat treatment. Our expertise ensures the right alloy aligns with your product's demands for durability, corrosion resistance, and performance.

However, our commitment to your vision doesn't end at the casting gate. We provide a complete suite of secondary operations and surface treatments to deliver a ready-to-use product. Our in-house CNC machining centers perform precise drilling, milling, and tapping for critical tolerances. Afterwards, parts can be enhanced with finishes like durable powder coating for color and protection, elegant polishing for a reflective shine, or subtle brushing for a sophisticated matte texture. This integrated approach to custom aluminum alloy die casting guarantees seamless quality control from raw metal to finished component.

Why Partner with Us? The Integrated Manufacturer Advantage

Choosing us as your aluminum die casting partner means accessing a vertically integrated service model designed for reliability and ease.

From Design to Delivery:

We support your entire journey, beginning with expert DFM (Design for Manufacturability) analysis on your Solidworks, STEP, or IGES files to prevent costly errors. Our mold-making workshop, utilizing premium steels like H13 and 718, builds the robust tooling required for long production runs.

Speed and Flexibility to Market:

We champion agility. Submit your inquiry and receive a competitive quotation promptly. We support prototype development with low MOQs, aiming to deliver initial samples for your evaluation in a matter of days, not weeks, accelerating your product development cycle.

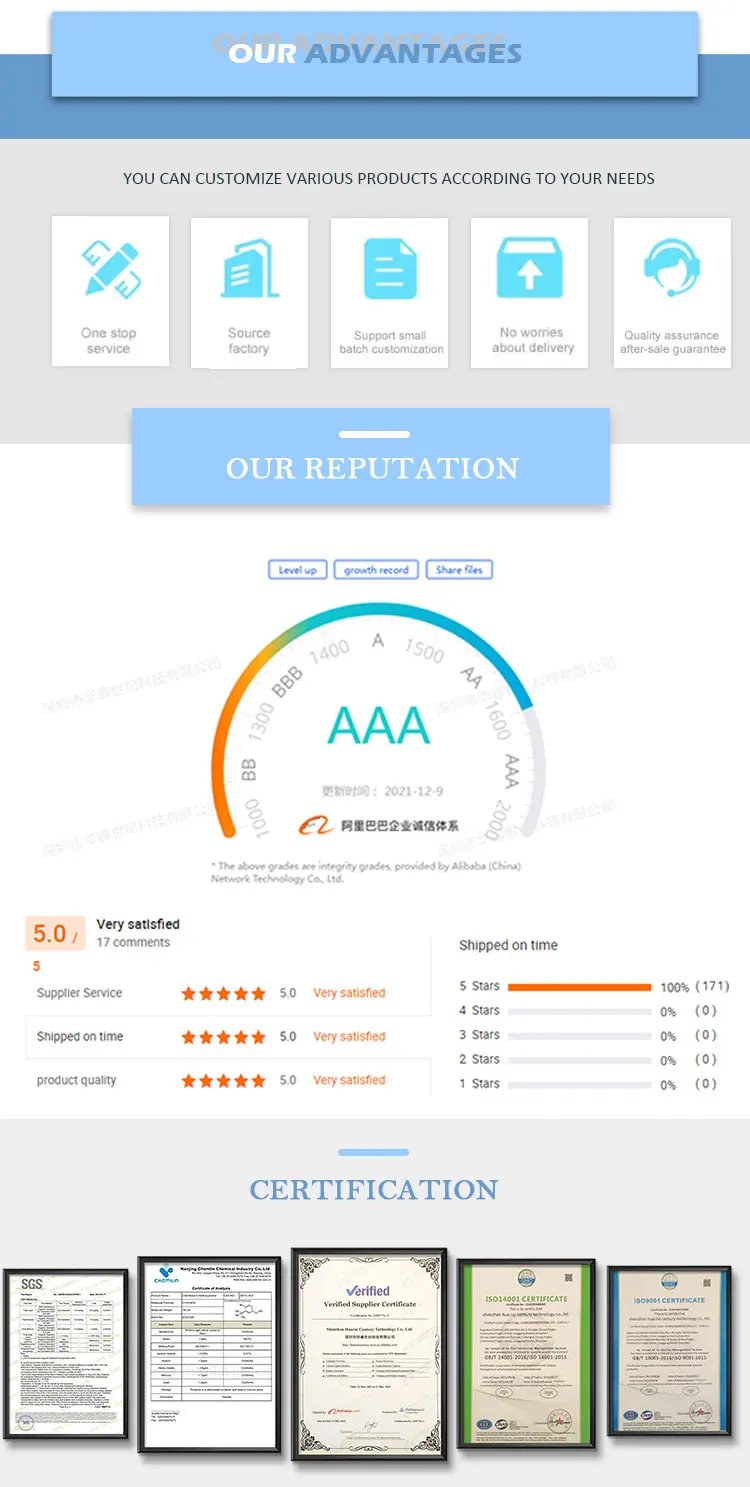

A Covenant of Quality and Reliability:

Our commitment is underpinned by an ISO 9001-certified quality management system. Every batch of precision aluminum die casting parts undergoes rigorous inspection, ensuring they not only meet but exceed your expectations. We view our role as an extension of your production floor, dedicated to becoming your most dependable source for high-quality aluminum die casting components.

Transforming Industries: The Versatility of Die Cast Parts

The inherent benefits of aluminum die casting—strength, lightness, and design flexibility—make it indispensable across various applications. In furniture manufacturing, it creates sturdy, ornate hinges, locks, and structural brackets that combine aesthetics with longevity. For industrial fittings, it produces consistent, reliable housings, levers, and connectors that withstand operational stresses. In the realm of construction and decoration, it enables the production of complex, weather-resistant architectural hardware and decorative elements with fine detail. This aluminum die casting service is the engine behind innovative, durable products in these dynamic markets.

Begin Your Project: A Streamlined Path to Production

Initiating your custom aluminum die casting project is a straightforward, collaborative process designed for clarity and efficiency. It begins with you sharing your concepts or technical drawings with our engineering team. We then engage in a consultative review, providing insights and a formal quotation. Upon approval, we proceed to precision mold fabrication and initial sample casting for your validation. Once the samples receive your confirmation, we mobilize for full-scale production, integrating any specified deep processing and surface treatments, culminating in careful packaging and on-time delivery to your facility.