Oem laser cutting stainless steel metal products customized sheet metal stamping bending bracket parts

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

| Name | custom manufacturing sheet metal fabrication聽 parts service |

| Materials | Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

| Surface Treatment | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

| Tolerance | +/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Testing equipment | CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

| Processing | Stamping ,Sheet metal fabrication |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Our Advantages | 1.) 24 hours online service & Quickly Quote/Delivery. |

| 2.) 100% QC quality inspection before delivery, and can provide quality inspection form. | |

| 3.) To provide production design, production and technical service, mould development and processing, etc |

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. provides high-precision laser cutting and sheet metal fabrication services for a wide range of industrial applications. Our expertise is focused on producing custom stainless steel, aluminum, and steel components, including brackets, panels, mounting plates, and enclosures, through laser cutting, stamping, and bending processes.

-

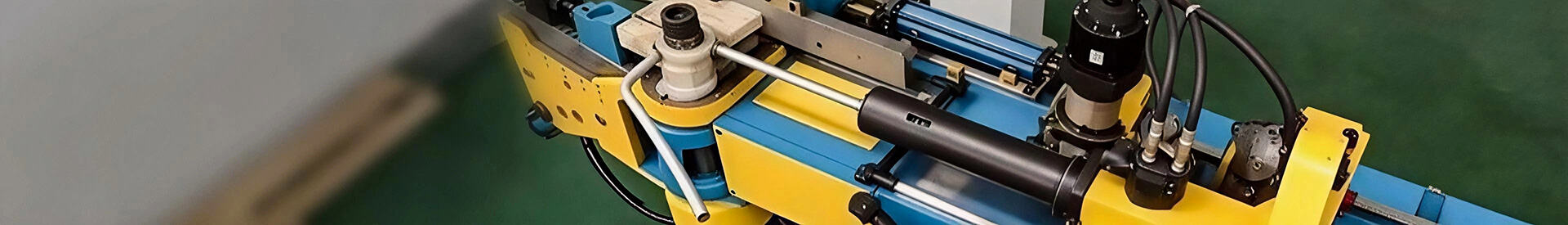

Precision Laser Cutting: Utilizing advanced CNC laser systems, we achieve smooth edges, high dimensional accuracy, and intricate cut patterns on stainless steel, aluminum, and other metal sheets. This ensures components fit precisely in assemblies and reduces post-processing needs.

-

Custom Sheet Metal Stamping: We transform flat sheets into three-dimensional structures with structural rigidity, enabling the production of brackets, supports, and housings designed for industrial machinery, electronics, and automotive systems.

-

CNC Bending & Forming: Our CNC press brakes and bending systems perform multi-angle bends, progressive bends, Z/U shapes, and complex forms, ensuring the final components conform exactly to client specifications while maintaining material strength.

-

Flexible Material Capability: We work with stainless steel, aluminum, pre-coated, and pre-treated metal sheets, accommodating diverse project requirements for corrosion resistance, mechanical strength, and lightweight design.

-

Rapid Prototyping & Mass Production: Shenzhen Huarui supports both small prototype batches and large-scale production runs, guaranteeing repeatable quality, fast turnaround times, and reliable supply.

-

Quality Assurance: All parts are subjected to 100% inspection, including dimensional verification, bend angle accuracy, and surface evaluation, ensuring high-quality results that meet industrial standards.

Our services cater to clients in electrical enclosures, ventilation systems, industrial machinery, furniture components, and decorative metalwork, providing precision, efficiency, and durability.

Product Advantages

1. Transforming Flat Sheets into Three-Dimensional Components

Through precision laser cutting and CNC bending, our service converts flat metal sheets into structurally robust three-dimensional parts. This process enables the creation of mounting brackets, enclosure panels, and support structures while optimizing weight and mechanical strength. Complex geometries, including Z-forms and U-forms, are achieved with high dimensional fidelity, essential for assembly-intensive applications.

2. High Repeatability and Production Efficiency

Shenzhen Huarui employs CNC-controlled bending and stamping equipment, which ensures consistent angles, uniform dimensions, and repeatable results across multiple production runs. This capability reduces material waste, minimizes post-production errors, and guarantees that even large-scale batches meet exacting specifications, providing clients with reliable parts ready for assembly.

3. Multi-Step and Complex Bending Capabilities

Our bending technology supports progressive bending sequences, hinge-style bends, and precise multi-step folds, enabling the production of components with intricate structural and aesthetic requirements. Each bending step is programmed to minimize interference, compensate for springback, and maintain surface integrity, ensuring both functionality and visual appeal.

Production Process

Shenzhen Huarui Century Technology Co., Ltd. follows a systematic production workflow to ensure precision, quality, and timely delivery of custom sheet metal components:

-

Design Evaluation & File Preparation: Clients provide CAD drawings, DXF files, or technical specifications. Our engineers review the design and propose optimal material choices, thicknesses, and bending sequences to enhance structural performance and manufacturability.

-

Material Procurement & Inspection: High-quality sheets of stainless steel, aluminum, or coated metals are sourced and inspected for flatness, surface quality, and dimensional consistency, ensuring optimal results in subsequent cutting and bending processes.

-

Laser Cutting: Using high-precision CNC laser machines, sheets are cut to specifications. This step produces clean, burr-free edges and enables intricate cutouts that facilitate assembly and reduce manual labor.

-

Stamping & Forming: Flat metal components are transformed through stamping and press operations. CNC-controlled presses ensure uniform bends, accurate flanges, and consistent structural features.

-

Bending & Progressive Folding: Components undergo multi-step bending, Z/U-shaping, or progressive bends according to the programmed sequence. Each bend is monitored for angle accuracy and surface quality, minimizing deformation and maintaining material strength.

-

Surface Treatment & Quality Checks: Depending on client requirements, components may undergo polishing, coating, or protective film application. Each part is inspected for dimensional accuracy, bend precision, and surface integrity, ensuring conformity with technical specifications.

-

Packaging & Delivery: Finished parts are packaged with protective padding or films to prevent scratches or damage during transit. Secure packaging ensures components reach clients in perfect condition, ready for assembly.

This structured production process ensures that Shenzhen Huarui delivers high-quality, consistent, and precisely engineered sheet metal parts for industrial and commercial applications.

Request a Quote for Custom Parts

Shenzhen Huarui Century Technology Co., Ltd. specializes in precision sheet metal fabrication services, offering:

-

Laser cutting, stamping, and bending of stainless steel, aluminum, and coated metals.

-

High repeatability, accuracy, and dimensional consistency across production batches.

-

Custom designs for brackets, enclosures, panels, and industrial components.

-

Flexible production volumes, from prototype runs to large-scale manufacturing.

Submit your design drawings, material preferences, and specifications to receive a personalized quotation. Partner with Shenzhen Huarui for reliable, high-quality, and precision-engineered metal components.

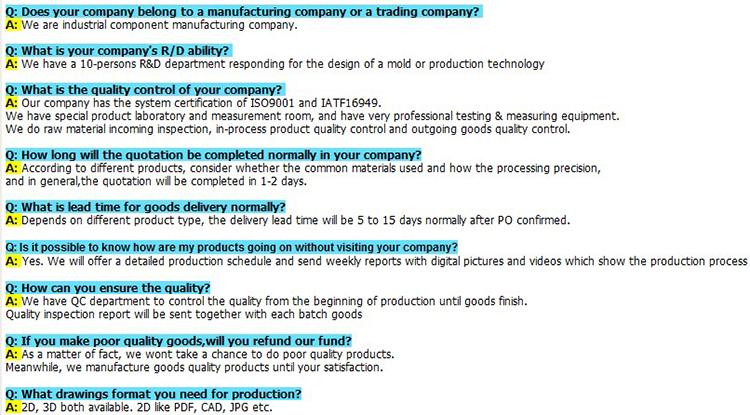

Frequently Asked Questions (FAQ)

Q1: What materials can you process?

A1: We process stainless steel, aluminum, steel, and coated sheet metals of various thicknesses.

Q2: Can you handle both prototypes and large production runs?

A2: Yes, we support small prototype batches as well as high-volume manufacturing, ensuring consistent quality.

Q3: What is the maximum bending angle achievable?

A3: Our CNC bending machines can achieve 0° to 180° bends with springback compensation.

Q4: Can you produce complex multi-step bends?

A4: Absolutely. We handle Z-shaped, U-shaped, progressive, and hinge-style bends according to design specifications.

Q5: Are surface treatments available?

A5: Yes, including polishing, anodizing, protective coating, and film application.

Q6: How is quality ensured?

A6: Every part undergoes 100% inspection, including dimensional verification, bend angle checks, and surface evaluation.

Q7: Do you support OEM and ODM manufacturing?

A7: Yes, we offer custom manufacturing solutions to meet specific client design and production requirements.

Q8: Can laser cutting and bending be integrated into a single workflow?

A8: Yes, our production process seamlessly combines laser cutting, stamping, and bending, delivering high-precision parts efficiently.