Custom wholesale CNC metal machine parts casting cnc machining parts metal stamping kit

Navigate the complexities of metal part manufacturing with our integrated solution. We provide expert guidance and execution across CNC machining, die casting, and metal stamping, tailoring the optimal process to your part's geometry, volume, and material—be it aluminum, steel, or stainless steel. From low-volume precision prototypes via CNC to high-efficiency mass production through casting or stamping, Our one-stop service ensures seamless transition, stringent quality control (±0.01mm capable), and significant cost optimization. Partner with us for a strategic, single-source approach to custom metal components that simplifies your supply chain and accelerates time-to-market.

Huarui

The Custom wholesale CNC metal machine parts casting cnc machining parts metal stamping kit provides quality and durability for all your metalworking requirements. Utilizing materials which are high-grade stainless, metal, aluminum, and copper, these personalized items are made to withstand probably the most challenging conditions.

With accuracy engineering and technology advanced Huarui's steel device components are manufactured to requirements that are precise. These components offer exact performance, time and time again whether you shall need customized CNC machining, die casting, or steel stamping.

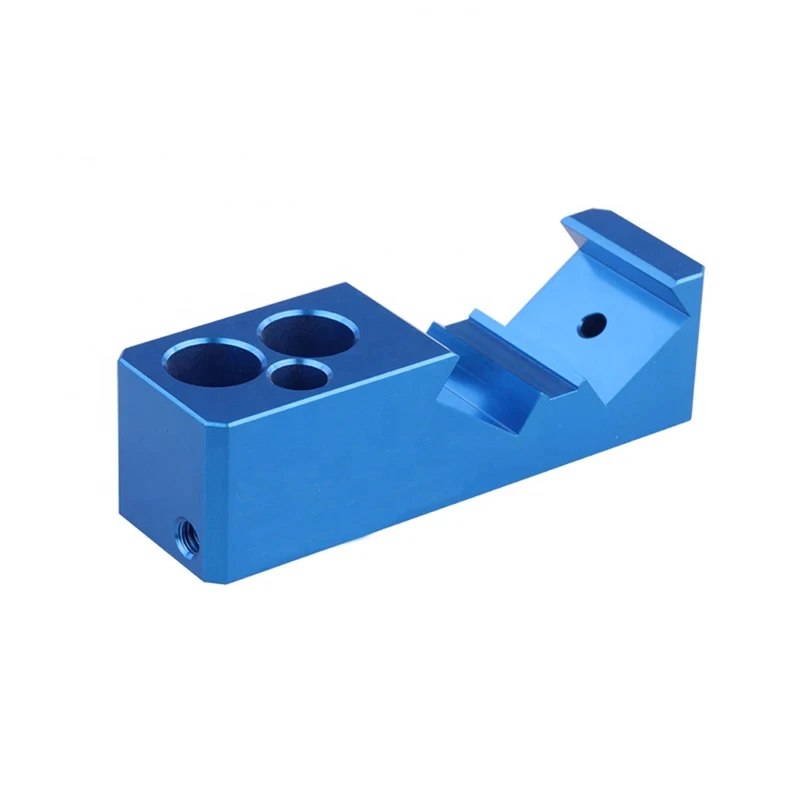

The machining that is CNC ensures that each component is crafted utilizing the level greatest of accuracy and precision feasible. Specialized pc software programming guarantees precision and persistence in each piece produced. This process can quickly manage complex forms and structures and provide completing that is exemplary possibly the tiniest details.

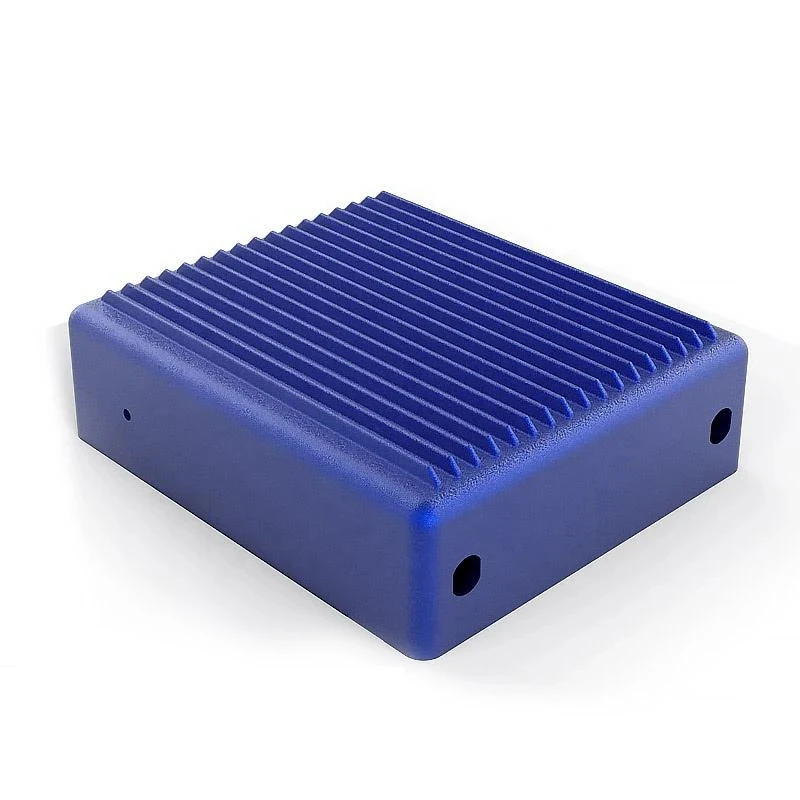

Die casting enables the creation of intricate, complex components which have both durability and strength. Huarui's die casting process uses advanced methods and cutting-edge gear to make accuracy components with tight tolerances, well suited for clients whom need more solutions which can be advanced.

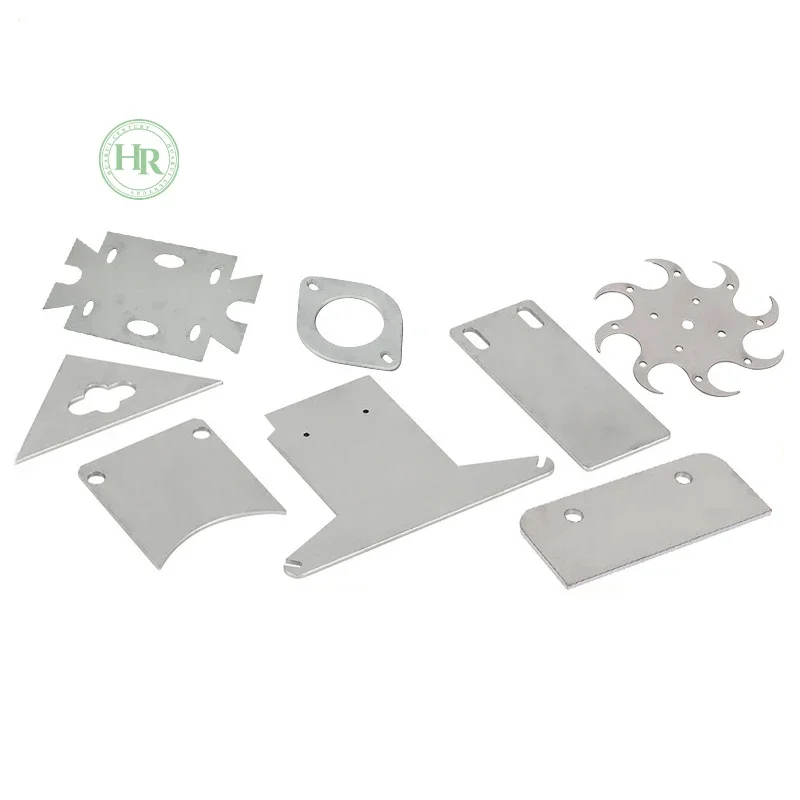

Huarui's steel stamping kit produces parts with less waste through the use of economical metal materials. Numerous actions are done making usage of device modern to produce accurate size and shapes. The employment of high accuracy stamping equipment enhances these technologies which will make an operation that 's almost perfect.

Made for maximum effectiveness and efficiency, Huarui's customized CNC that is wholesale steel components are an easy task to purchase and today have a turnaround time that is quick. The goods could be tailor-made to generally meet your specs being unique such as the types of steel, size, form, and application. Huarui is merely a brand that is trusted with a long period of experience creating quality products which will allow you to cut your manufacturing expenses down.

item |

value |

We are based in Guangdong, China, start from 2013, sell to Mid East(28.00%), North America(25.00%), Western Europe(20.00%), South America(10.00%), Northern Europe(7.00%), Oceania(5.00%), Southern Europe(5.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us?

Stamping Part Products, Lathe Part Products, Die Casting Products, Aluminum Profile, Spring

4. why should you buy from us not from other suppliers?

Our company was in hardware parts more than 10 years, provide high-qualified products and competitive price, more than 10 technicians on casting, stamping, lathe and other metals parts, we have compeletely production line and quality-checking line.

5. what services can we provide?

Accepted Delivery Terms: FOB, CIF, EXW;

Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, CNY;

Accepted Payment Type: T/T, L/C, PayPal, Western Union;

Language Spoken: English, Chinese

Selecting the right manufacturing process for a custom metal part is often a critical but complex decision, with implications for cost, lead time, and part performance. Relying on a supplier who masters only one technology can lead to suboptimal outcomes. Our service is built on a different principle: integrated manufacturing expertise. As a comprehensive custom metal parts manufacturer, we offer and expertly advise on CNC machining, die casting, and metal stamping. This empowers us to act as your unbiased manufacturing consultant, recommending and executing the most efficient and cost-effective path for your specific project, whether you need ten precision prototypes or ten thousand production units. Choosing us means choosing a partner focused on your total project success, not just filling a machine’s schedule.

The Manufacturing Toolkit: Decoding CNC Machining, Die Casting, and Stamping

Understanding the core strengths of each technology is the first step to optimization. CNC machining is the champion of flexibility and precision. It creates parts by subtracting material from a solid block, allowing for complex 3D geometries, rapid design changes, and exceptional tolerances as tight as ±0.01mm. It is ideal for prototypes, low to medium volumes, and parts requiring the highest accuracy. Die casting is a high-pressure process where molten metal is forced into a reusable mold. It excels at producing high volumes of complex, net-shape parts with excellent surface finish and dimensional consistency, making it perfect for aluminum or zinc alloy housings and components. Metal stamping utilizes dies and presses to form or cut sheet metal into specific shapes at tremendous speed and low per-part cost, ideal for creating brackets, contacts, and enclosures in massive quantities from steel or stainless steel.

From Blueprint to Best Path: Our Consultative Process Selection

How do we determine the right path for your part? It begins with a collaborative analysis. We examine your design, material preferences, required quantity, budget, and performance criteria. For a complex, low-volume stainless steel component, CNC machining is likely the clear choice. For a high-volume aluminum enclosure with thin walls and intricate details, die casting offers the best economics. For a simple, flat steel bracket needed in the hundreds of thousands, metal stamping provides unbeatable efficiency. Our engineers provide a clear, data-backed recommendation, often including Design for Manufacturability (DFM) feedback to optimize your part for the selected process, reducing cost and improving reliability. This consultative approach ensures you invest in the right technology from the start.

Seamless Scaling: Bridging Prototype Development and Volume Production

Many innovative products face a critical valley between prototype validation and full-scale manufacturing. Our integrated capabilities uniquely position us to bridge this gap. A part can be initially prototyped and refined using our high-precision CNC machining services, allowing for fast iterations and functional testing. Once the design is frozen and volumes justify it, we can seamlessly transition the project to our die casting or stamping division for production. This continuity eliminates the friction, requalification costs, and communication gaps typically encountered when switching suppliers. We manage the entire tooling design and fabrication process in-house, ensuring the production parts faithfully reflect the proven prototype. This makes us an invaluable partner for startups and established companies alike.

Uncompromised Quality Across All Processes

Regardless of the chosen manufacturing process, our commitment to quality remains unwavering. Our operations are underpinned by a rigorous ISO-certified quality management system. For CNC machined parts, we employ CMMs and advanced metrology to verify micron-level precision. For die cast and stamped parts, we implement Statistical Process Control (SPC) and perform first-article and in-process inspections to ensure consistency across thousands of cycles. We uphold a strict 100% quality inspection before delivery policy for critical dimensions and provide comprehensive inspection reports. This systemic approach to quality guarantees that every component leaving our facility, whether a one-off custom piece or a batch from a production run, meets the highest standards of excellence and reliability.

Driving Value Across Industries: Application-Specific Solutions

Our multi-process expertise delivers tangible value across diverse sectors. In the consumer electronics industry, we might CNC machine a prototype aluminum chassis, then die cast the final version for mass production. For the automotive sector, we produce precision CNC machined sensor housings and high-volume stamped brackets or electrical contacts. Industrial equipment manufacturers rely on us for robust stamped steel frames, die cast gearbox housings, and CNC machined high-wear components. This breadth of experience means we not only understand manufacturing processes but also the specific performance, regulatory, and supply chain demands of your industry, allowing us to deliver truly fit-for-purpose metal parts.

The Tangible Benefits of a Single-Source Manufacturing Partner

Consolidating your custom metal parts supply with a single, integrated partner like us yields significant strategic advantages. It reduces administrative overhead by eliminating the need to manage multiple suppliers. It minimizes project risk through expert-guided process selection and seamless phase transitions. It often lowers total cost by optimizing the design for the most economical process and avoiding costly missteps. Furthermore, it accelerates time-to-market through streamlined communication and coordinated project management. In essence, we become an extension of your engineering and operations teams, dedicated to the efficient realization of your product vision.

Initiating Your Integrated Manufacturing Project

Beginning a partnership is a straightforward, collaborative process. Share your part drawings, samples, or concepts with our team. We will schedule a technical consultation to discuss your needs in detail. Following this, you will receive a comprehensive proposal that includes our recommended manufacturing process, material analysis, a transparent cost breakdown, and a projected timeline. Upon your approval, a dedicated project manager will guide your order through every stage, from tooling design to final delivery, keeping you informed with regular updates. We are committed to providing not just parts, but a smarter, more reliable, and more efficient way to bring your metal components to life.