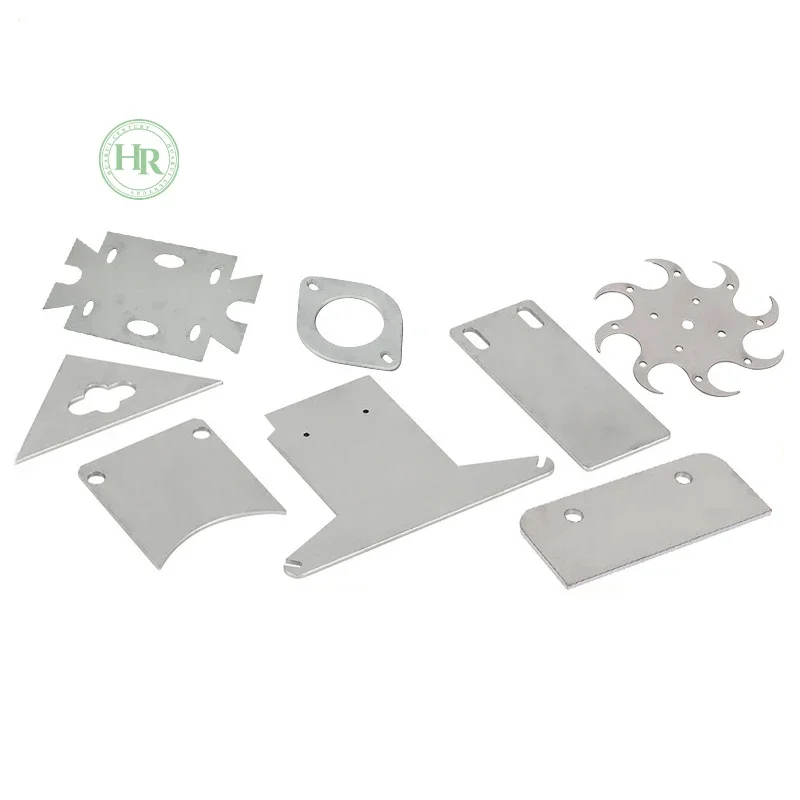

Custom OEM Multi-Material Sand Casting: Aluminum, Iron, Steel, Brass Parts

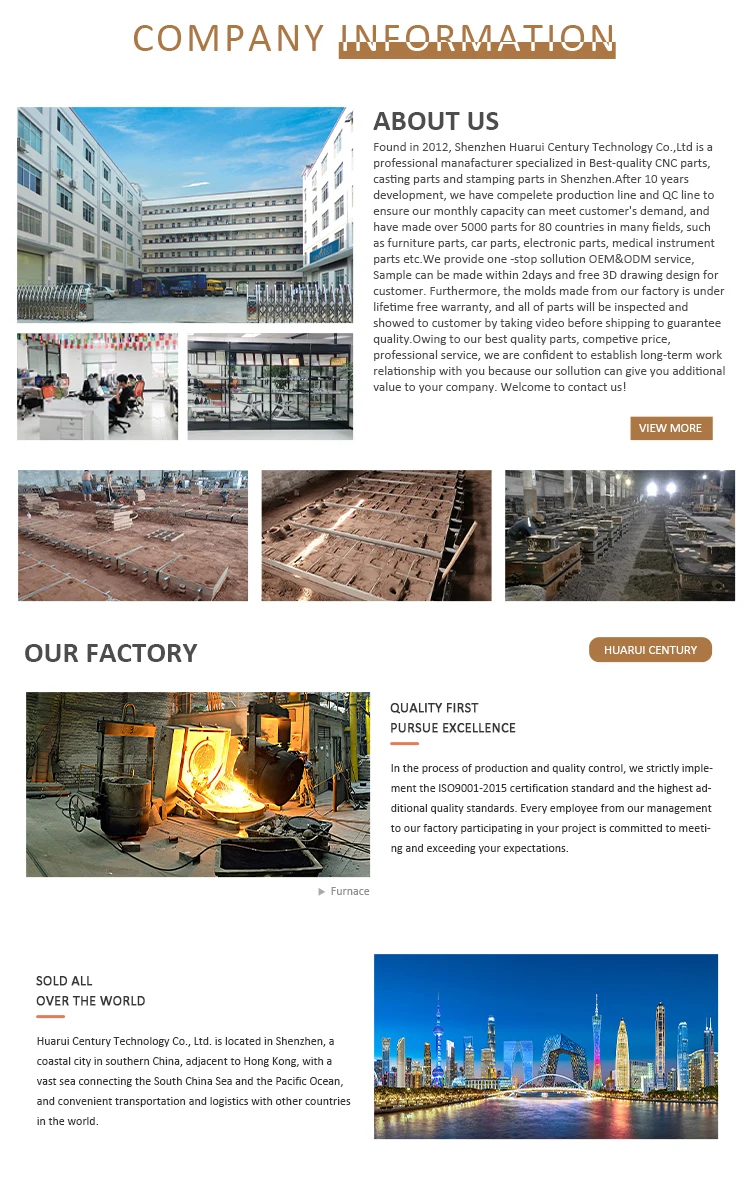

Simplify your supply chain with our comprehensive, one-stop sand casting service for a wide spectrum of high-performance metals. We specialize in custom manufacturing of precision parts using aluminum alloys, strong and ductile iron, corrosion-resistant stainless steel, and decorative brass or bronze. Our integrated process supports full customization from prototype to production, including expert finishing like anodizing, plating, and powder coating. Certified to ISO 9001, ISO 14001, and compliant with RoHS/REACH, we are a reliable manufacturer delivering quality cast parts for automotive, industrial, marine, medical, and architectural applications worldwide.

Product Description |

Oem sand casting parts |

Material |

Grey Iron, Ductile Iron, Steel, Stainless Steel, Aluminum, Brass, Bronze. |

Surface Treatment |

Polishing, sand blasting, heat treatment, painting, powder coating, anodizing,electroplating, Chrome plating, mirror polishing. |

Standard |

ISO9001,epr,lso14001,RoHS,REACH,etc. |

Size |

1.According to your 2D, 3D Drawing. 2.As per the customer’s samples. |

Payment terms |

T/T, L/C, Money Gram, PayPal, Crash, Western Union. |

application |

All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on. |

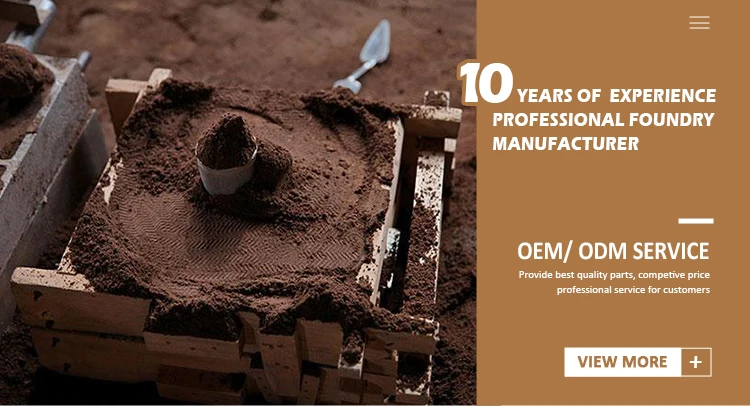

One Foundry, Endless Possibilities: Your Multi-Material Sand Casting Partner

Navigating the complexities of sourcing metal components often means dealing with multiple suppliers for different materials—a process that is time-consuming and fraught with logistical challenges. In today's competitive manufacturing landscape, efficiency and reliability are paramount. This is the core problem our integrated multi-material sand casting service solves. We are not just a foundry; we are your single-source manufacturing partner, equipped to expertly handle aluminum, ductile iron, stainless steel, brass, and more under one roof. Our mission is to provide a seamless, reliable, and high-quality casting solution that empowers your designs, streamlines your production, and delivers durable components tailored for their specific application, from heavy-duty industrial use to aesthetic architectural details.

The Power of Choice: Selecting the Perfect Material for Your Application

The foundation of a superior component lies in selecting the optimal material. Our diverse capabilities allow us to guide you to the best choice, balancing performance, cost, and design requirements.

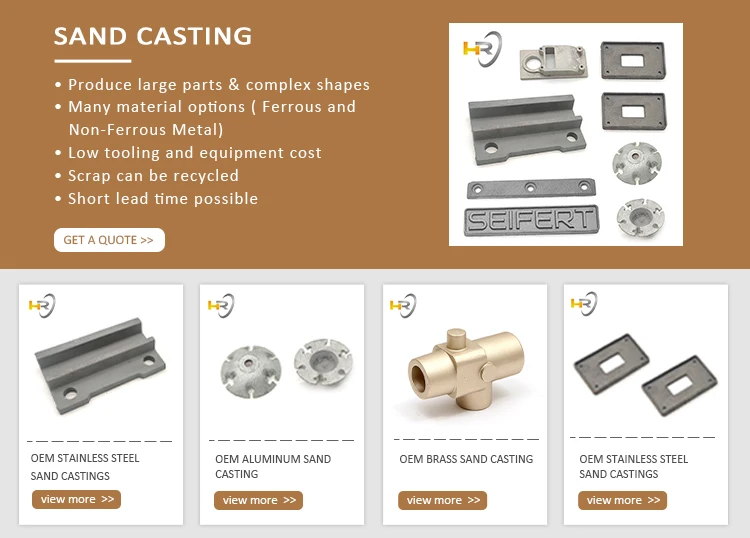

Aluminum Castings: The Leader in Lightweight Strength

Aluminum sand casting is a cornerstone of modern manufacturing, prized for its exceptional strength-to-weight ratio. Parts produced through this process offer excellent corrosion resistance and good thermal conductivity, making them ideal for automotive components, aerospace fittings, marine hardware, and complex lighting fixtures. The sand casting method allows for the creation of large, structurally sound aluminum parts that are both lightweight and durable.

Ductile Iron Castings: Unmatched Durability for Demanding Environments

When your application requires supreme strength, toughness, and excellent wear resistance, ductile iron (also known as nodular iron) is the material of choice. Its unique microstructure gives it mechanical properties superior to standard grey iron, including significant elongation and impact resistance. This makes ductile iron sand casting perfect for high-stress components such as heavy-duty pump housings, valve bodies, hydraulic parts, and large machine tool bases that must withstand immense pressure and shock loads.

Stainless Steel Castings: Superior Resistance Meets Strength

For parts that must perform in corrosive, high-temperature, or hygienically critical environments, our stainless steel sand casting service delivers. Stainless steel offers excellent resistance to rust, oxidation, and a wide range of chemicals. This, combined with its inherent strength, makes it indispensable for medical equipment parts, food processing machinery, chemical plant components, marine fittings, and architectural elements exposed to harsh weather.

Brass and Bronze Castings: Where Function Meets Elegance

Brass and bronze alloys are selected for their excellent machinability, natural corrosion resistance, distinctive appearance, and good bearing properties. Brass sand casting produces parts with a warm, golden hue, ideal for decorative hardware, architectural accents, musical instrument components, and marine fittings. Bronze castings are often used for bushings, gears, and statuary due to their wear resistance and classic aesthetic.

The Sand Casting Advantage: Flexibility for Complex and Custom Designs

The sand casting process is uniquely capable of bringing your diverse material choices to life with remarkable flexibility. Unlike other high-volume processes, sand casting is exceptionally well-suited for low to medium production runs, very large part sizes, and components with intricate internal geometries or complex cores. We create a custom sand mold for each casting, which allows for significant design freedom and cost-effective prototyping without the need for expensive permanent tooling. This makes our sand casting service the ideal choice for custom projects, specialized machinery parts, and large architectural elements where other methods are impractical or too costly.

Beyond the Mold: Integrated Finishing and Machining for Ready-to-Use Parts

We deliver more than just raw castings; we provide finished components. Our vertical integration extends to a complete suite of secondary services that add critical value. Our in-house machine shop handles precision CNC machining, drilling, tapping, and milling to achieve exact dimensional tolerances and ready-to-assemble features. Furthermore, our extensive surface treatment department offers everything from basic sand blasting and polishing to advanced anodizing for aluminum, electroplating (including chrome), and durable powder coating in any color. This end-to-end capability ensures your sand casting parts arrive fully finished, saving you time, cost, and the complexity of managing multiple vendors.

A Foundation of Quality: Certifications and Process You Can Trust

Every component we produce is backed by a rigorous, systemized approach to quality. Our operations are certified under the ISO 9001 quality management standard, ensuring consistent processes and continuous improvement. We are also compliant with international environmental and safety directives, including RoHS and REACH, which is crucial for products entering global markets like the European Union. Our quality control begins at the material certification stage and continues through every step of the sand casting process, including meticulous pattern inspection, mold quality checks, and final dimensional verification. This commitment provides you with the assurance that you are partnering with a professional manufacturer dedicated to delivering reliable, high-quality castings.

Engineered for Industry: Proven Applications Across Sectors

The versatility of our service is demonstrated by its wide-ranging applications. In the automotive and railroad sectors, we produce durable engine brackets, suspension components, and brake system parts from ductile iron and aluminum. For marine and medical industries, we manufacture corrosion-resistant stainless steel and aluminum fittings, housings, and equipment parts. The architectural and furniture fields utilize our ability to create both structural aluminum elements and decorative brass or bronze hardware. Additionally, we serve the industrial and lighting sectors with complex pump bodies, valve castings, and heat-sink-friendly aluminum light fixtures. No matter your industry, our multi-material expertise ensures we can meet your specific technical and aesthetic requirements.

Your Partner from Concept to Delivery

Initiating a project with us is designed for clarity and collaboration. We accept your design input in all standard 2D and 3D formats (DWG, STEP, IGES, Solidworks) or can work from a physical sample. Our engineering team provides constructive design-for-manufacturability feedback to optimize your part for the sand casting process, enhancing quality and potentially reducing cost. We believe in transparent pricing and timelines, providing detailed quotations to inform your decision.

As an experienced manufacturer based in China, we are committed to building lasting partnerships through reliable communication, on-time delivery, and consistent quality. We understand the needs of global buyers and are equipped to support your supply chain with flexible solutions. We invite you to consolidate your casting needs with a single, capable partner. Contact us today to discuss your multi-material project, request a quote for your sand casting parts, and discover how our integrated service can contribute to the success of your next product.