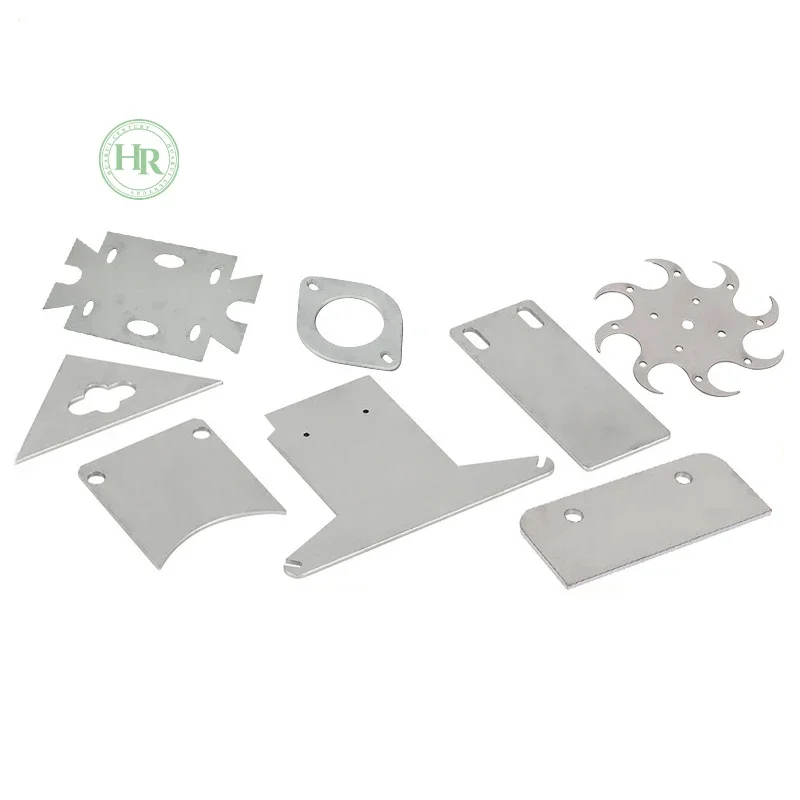

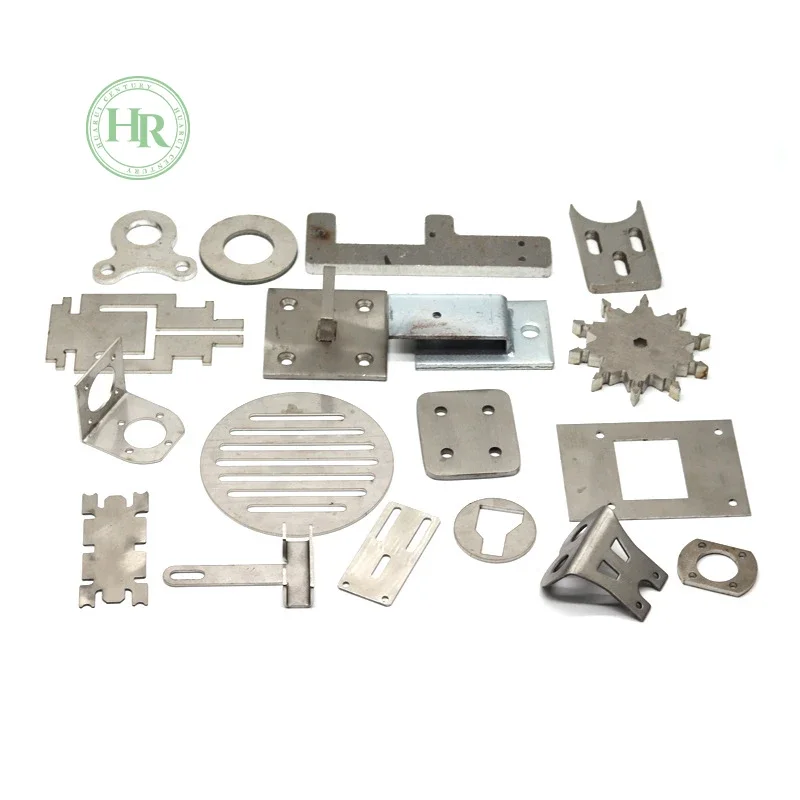

Custom Sheet Metal Part Fabrication Aluminum Stainless Steel metal laser cutting bending parts laser cutting service

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

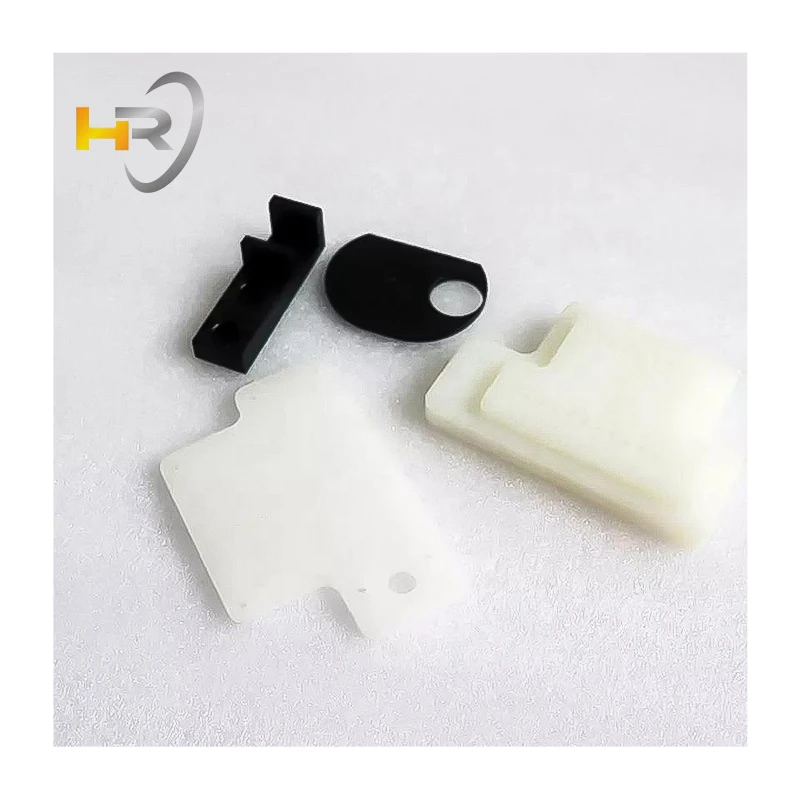

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Name |

custom manufacturing sheet metal fabrication parts service |

Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Processing |

Stamping ,Sheet metal fabrication |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Our Advantages |

1.) 24 hours online service & Quickly Quote/Delivery. 2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) To provide production design, production and technical service, mould development and processing, etc |

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. provides professional Custom Sheet Metal Part Fabrication Aluminum Stainless Steel metal laser cutting bending parts laser cutting service for global industrial customers seeking high-performance metal components and rapid customization capabilities. Our integrated fabrication solutions include laser cutting, CNC bending, and precision forming, delivering exceptional accuracy and structural reliability across all types of sheet metal designs.

Our production is supported by advanced digital manufacturing systems, allowing us to process a wide range of materials including stainless steel, aluminum, carbon steel, copper, and coated metals. With highly automated workshop management and rigorous inspection standards, we ensure exact dimensional control and consistent quality from prototype to mass production.

Key performance features include:

-

Smooth and precise cutting for complex engineering profiles

-

Excellent edge quality for subsequent welding or finishing

-

High material strength retention due to low thermal impact

-

Efficient deformation control during bending and forming

-

Strong durability suitable for industrial loading and impact conditions

-

Fast production cycles enabling on-demand delivery

Our parts are widely used in machinery equipment, communication cabinets, consumer product housings, automotive structures, medical devices, robotics frames, and other high-accuracy assemblies requiring excellent stability and long service life.

Core Advantages

Excellent Repeatable Accuracy for Precision Components

Our laser cutting system maintains extremely tight part tolerances, ensuring stable geometric precision even in repeated high-volume production. The dimensional consistency supports fast installation and reduces assembly alignment challenges. This is especially valuable when producing complex brackets, mounting plates, and mechanical connection parts.

Flexible Processing for Multi-Material Fabrication

We support cutting and bending operations for multiple material types without requiring specialized tooling or mold investments. This reduces overall development costs and accelerates production timelines. Engineers can modify product configurations quickly, making this fabrication service highly suitable for customized product upgrades, small-batch manufacturing, and transition from prototype to commercialization.

High-Efficiency Production with Advanced Automation

Digital nesting software maximizes sheet utilization while minimizing material waste. Automated cutting and bending equipment enables continuous operation, shorter production cycles, and lower unit costs. With remote programming and CAD/CAM integration, design files can be updated instantly and transferred directly into manufacturing execution systems. Buyers benefit from both faster lead times and reduced overall cost of ownership.

Application Scenarios

Telecommunications and Electrical Installations

Our sheet metal fabrication service supports enclosure systems, cable trays, control panels, heat-ventilation covers, and structural internal components requiring precise perforations and rigid support.

Automotive and Transportation Industries

Used for interior metal brackets, chassis reinforcement, charging device covers, and lightweight safety structures that demand both flexibility of design and long-term durability.

Industrial Machinery and Production Lines

Widely applied to machine frames, mounting fixtures, conveyor system components, sensor protection covers, and other high-strength metal infrastructure parts.

These application areas demonstrate the strong adaptability of our Custom Sheet Metal Part Fabrication Aluminum Stainless Steel metal laser cutting bending parts laser cutting service to various mechanical environments and engineering standards.

Customization Process

Step-by-Step Workflow

To ensure highly reliable manufacturing performance and efficient order execution, Shenzhen Huarui Century Technology Co., Ltd. follows a standardized custom development management process:

-

Technical Consultation and Requirement Confirmation

-

Review drawings, materials, tolerances, and surface finishing requirements

-

Engineering feasibility evaluation provided to optimize manufacturability

-

-

Project Quotation and Schedule Planning

-

Detailed pricing based on processing complexity and batch size

-

Production scheduling established to meet the delivery timeline

-

-

Prototype Fabrication and Dimensional Assessment

-

First-article sample created for customer evaluation

-

Dimensional validation and design refinement based on testing feedback

-

-

Batch Production with Real-Time Quality Control

-

Digital traceability applied throughout cutting, bending, stamping, and welding

-

In-process inspection ensures stable conformity to specifications

-

-

Finishing, Packaging, and Shipment

-

Optional powder coating, anodizing, plating, and polishing

-

Custom packaging to ensure safe international logistics

-

This workflow supports both rapid prototyping cycles and long-term supply chain cooperation with global OEM clients.

Contact Us for Your Custom Project

We welcome business buyers, product design teams, and equipment manufacturers to partner with us for precision sheet metal fabrication. For an accurate quotation, please include:

-

Engineering drawings (STEP, STP, DXF, DWG, or PDF)

-

Required materials, thickness, and tolerances

-

Surface finishing and special functional needs

-

Estimated quantity and delivery expectation

Our technical specialists will provide expert support with optimized production solutions designed to elevate product quality and reduce cost.

FAQ

Q1: What is the minimum order quantity?

We support any quantity from prototypes to mass-produced orders.

Q2: Can you process parts with highly complex patterns?

Yes, our laser cutting equipment is designed for precise detailing including micro-holes, fine mesh, and multi-geometry contours.

Q3: What drawings can you work with?

We accept industry-standard CAD files such as DXF, DWG, STP, STEP, and PDF.

Q4: Do you offer welding and surface finishing services?

Yes, we provide TIG/MIG welding, spot welding, powder coating, anodizing, plating, and brushed finishing.

Q5: How do you ensure quality?

We conduct material inspection, dimensional measurement, structural testing, and full traceability throughout the production process.

Q6: Do you ship worldwide?

Yes, we have established export experience in multiple regions including Europe, North America, and Southeast Asia.