Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Product Overview

5 Axis Custom Brass Case Gear for Turning CNC Machining Parts – CNC Lathe Machine Parts

Shenzhen Huarui Century Technology Co., Ltd. is a leading provider of high-precision CNC machining services, specializing in custom brass case gears, 5-axis CNC turning, and lathe machining components. Our company serves industries ranging from automotive and electronics to instrumentation, industrial machinery, and decorative hardware, providing high-quality components that meet the exacting demands of modern engineering applications.

Our custom CNC machined brass gears are manufactured according to client-provided drawings, CAD designs, or 3D models, ensuring precise dimensional accuracy, tight tolerances, and smooth surface finishes. These gears are optimized for high-speed rotational applications, mechanical linkages, and precision assemblies, where performance, durability, and reliability are critical.

Precision Engineering and Capability

Equipped with state-of-the-art 5-axis CNC machines, automated lathes, milling centers, and turning systems, we can produce intricate geometries, internal and external gear profiles, and fine-featured components with exceptional consistency. Our combination of experienced CNC programmers and skilled machinists allows us to maximize machining efficiency while ensuring superior quality and repeatability.

Material Versatility

We offer machining across a broad range of metals, including brass, aluminum, stainless steel, bronze, copper, and steel alloys, allowing for customized size, thread, and surface finish requirements. Optional finishing processes, such as polishing, plating, anodizing, or coating, further enhance corrosion resistance, mechanical durability, and aesthetic appeal.

Quality Assurance

Every component undergoes rigorous 100% inspection, including dimensional verification, surface finish evaluation, thread accuracy, and material composition analysis. This ensures each part meets the highest performance standards, delivering long-term reliability and precise mechanical function.

Product Advantages

Superior Corrosion Resistance

Brass exhibits excellent resistance to water and oxidation, making these custom CNC machined gears suitable for valves, fluid-handling systems, marine equipment, and instrumentation exposed to humid environments. This corrosion resistance ensures extended service life, minimal maintenance, and reliable operation even under challenging conditions.

Exceptional Machinability

Brass is highly machinable, producing short, manageable chips that reduce tool wear and increase production efficiency. Utilizing our advanced 5-axis CNC machining technology, we achieve complex geometries, precise dimensions, and superior surface finishes, ensuring that gears operate with minimal friction and optimal mechanical performance.

Self-Lubricating and Low Friction Properties

Brass is naturally low-friction and self-lubricating, making it ideal for rotational assemblies, precision bearings, and sliding mechanisms. Combined with our CNC precision, these components demonstrate longer service life, stable operation, and superior resistance to wear, even in high-load or continuous-use scenarios.

High Surface Quality and Aesthetic Value

Brass provides a naturally golden appearance and can be polished or plated to enhance both visual and functional quality. Our CNC machining ensures complex geometries and consistent high-quality finishes, making the gears suitable for functional assemblies and decorative applications alike.

Broad Industrial Applications

These custom machined brass gears are widely used in automotive gearboxes, precision instruments, valves, musical instruments, industrial machinery, and decorative hardware. They combine precision, durability, corrosion resistance, and aesthetic appeal, fulfilling the requirements of diverse engineering and commercial applications.

Production Process

Step 1: Design and Technical Review

Clients submit technical drawings, CAD files, or 3D models, which are carefully analyzed by our engineering team for manufacturability, tolerance compliance, and machining optimization. We provide feedback and recommendations to ensure parts can be produced efficiently without compromising quality.

Step 2: Material Selection and Inspection

We source high-grade brass, aluminum, stainless steel, and steel alloys with verified chemical composition, hardness, and surface quality. Incoming materials undergo thorough inspection, including visual checks, hardness testing, and dimensional verification, guaranteeing consistency across production batches.

Step 3: CNC Programming and Tooling

CNC programs are meticulously developed to meet design specifications, tolerance requirements, and surface finish standards. Cutting tools are carefully selected to reduce heat generation, minimize wear, and optimize machining efficiency, ensuring repeatable high-quality results.

Step 4: Precision Machining

Parts are machined using 5-axis CNC turning, milling, drilling, and lathe operations. This process allows for intricate gear teeth, precise bores, threads, and surface finishes to be produced with tight tolerances and high dimensional stability.

Step 5: Surface Treatment and Finishing

Optional finishing processes, including polishing, plating, coating, or anodizing, improve corrosion resistance, wear resistance, and visual appeal. CNC precision ensures uniform treatment across complex geometries and fine features.

Step 6: Quality Control and Verification

All parts undergo 100% inspection, including dimensional checks, thread verification, surface finish evaluation, and material testing. Components meeting strict standards proceed to packaging and shipment, ensuring consistent quality for all customers.

Step 7: Packaging and Delivery

Finished components are carefully packaged and labeled, with logistics options tailored for timely delivery both domestically and internationally. Bulk or customized shipments are handled efficiently, ensuring safe transportation and minimal risk of damage.

Technical Parameters

| Parameter | Specification |

|---|---|

| CNC Machining | Yes |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Stainless Steel, Steel Alloys, Hardened Metals, Precious Metals |

| Place of Origin | Guangdong, China |

| Type | Broaching, Drilling, Etching/Chemical Machining, Laser Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining | Yes |

| Model Number | NO |

| Brand Name | HUARUI |

| Size | Customized |

| Color | Customized |

| Tolerance | Customer’s Drawing Request |

| OEM/ODM | Accepted |

| Quality Control | 100% Inspection |

Inquiry and Contact

Experience high-precision CNC machining of custom brass gears and mechanical components at competitive factory pricing. Submit your drawings, CAD files, or specifications to Shenzhen Huarui Century Technology Co., Ltd., and receive a customized quotation and production plan.

Our engineers provide material recommendations, machining strategies, and surface finish optimizations, ensuring your parts meet strict performance and quality standards.

Request your inquiry today to partner with a reliable OEM manufacturer for high-quality 5-axis CNC turning, lathe, and milling services.

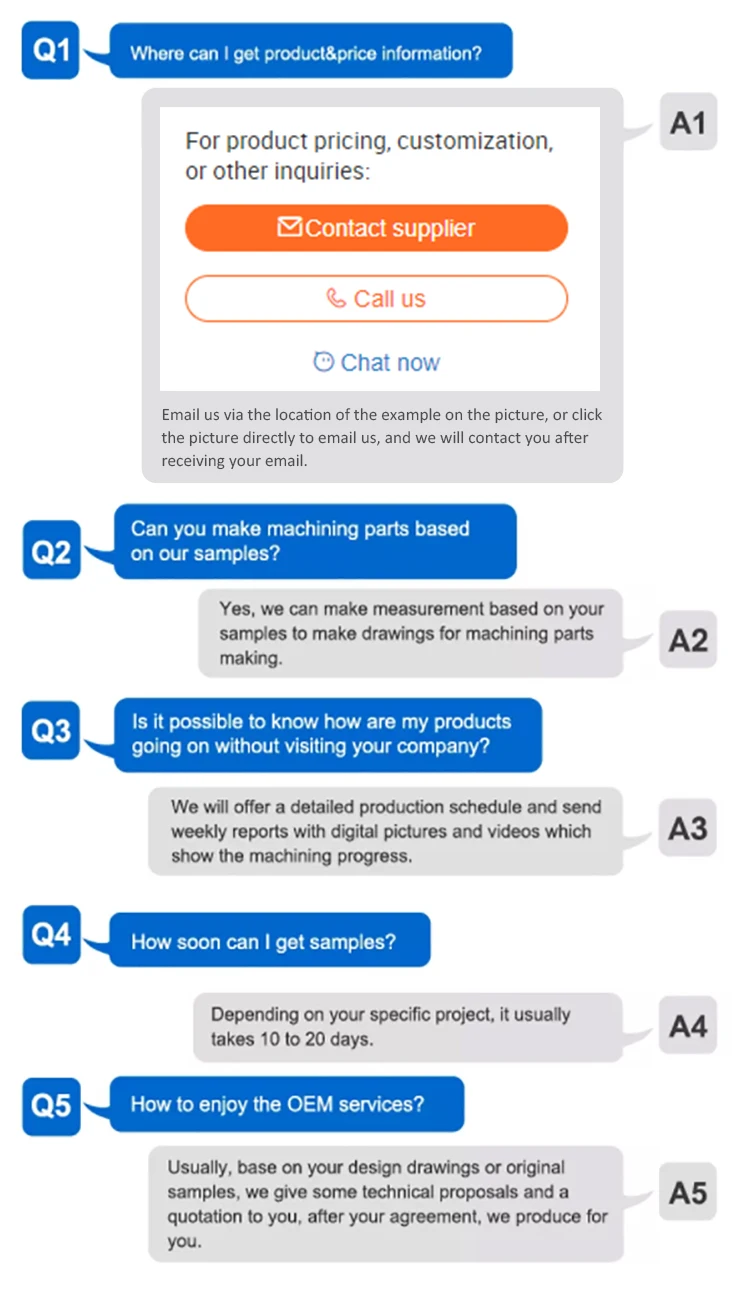

Frequently Asked Questions (FAQ)

Q1: What metals are supported for CNC machining?

A: We machine brass, aluminum, stainless steel, copper, bronze, and steel alloys, including hardened and precious metals.

Q2: Can you produce high-precision small gears?

A: Yes, our 5-axis CNC machines and automated lathes can create intricate gears and components with tight tolerances.

Q3: Do you accept CAD or 3D model files?

A: Absolutely. We use CAD and 3D files for CNC programming to ensure precision machining.

Q4: Are finishing services available?

A: Yes, we offer polishing, plating, coating, and anodizing to enhance durability, aesthetics, and functional properties.

Q5: Can you handle prototypes and low-volume orders?

A: Yes, we support prototyping, small-batch production, and mass production.

Q6: Are OEM/ODM services available?

A: Yes. We offer full customization including material, dimension, surface finish, and packaging options.

Q7: How do you ensure quality consistency?

A: All parts undergo 100% inspection, including dimensional checks, thread accuracy, surface evaluation, and material testing, ensuring consistent quality.