Precision CNC Milling And Turning Parts Service For Aluminum And Stainless Steel

As an experienced manufacturer, Shenzhen Huarui Century Technology provides professional CNC milling and turning services, specializing in aluminum and stainless steel components. We deliver custom OEM parts with high precision up to +/-0.01mm tolerance, supported by comprehensive in-house capabilities from machining to surface treatment. Our rigorous quality control, utilizing advanced equipment like CMM, ensures every order meets exact specifications for applications across automotive, industrial machinery, and electronics.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

In today's competitive manufacturing landscape, the ability to source reliable, high-precision components is paramount for product performance and time-to-market. At Shenzhen Huarui Century Technology, we provide foundational manufacturing excellence through our dedicated CNC milling and turning service. This core offering encompasses the essential processes needed to create a vast array of CNC turning machining parts and complex milled geometries. Whether your project requires the lightweight properties of aluminum or the robust strength of stainless steel, our expertise ensures that every custom CNC milling part is produced to the highest standards of accuracy and quality, supporting your vision from prototype to production.

The Core of Manufacturing: Mastering Milling and Turning Processes

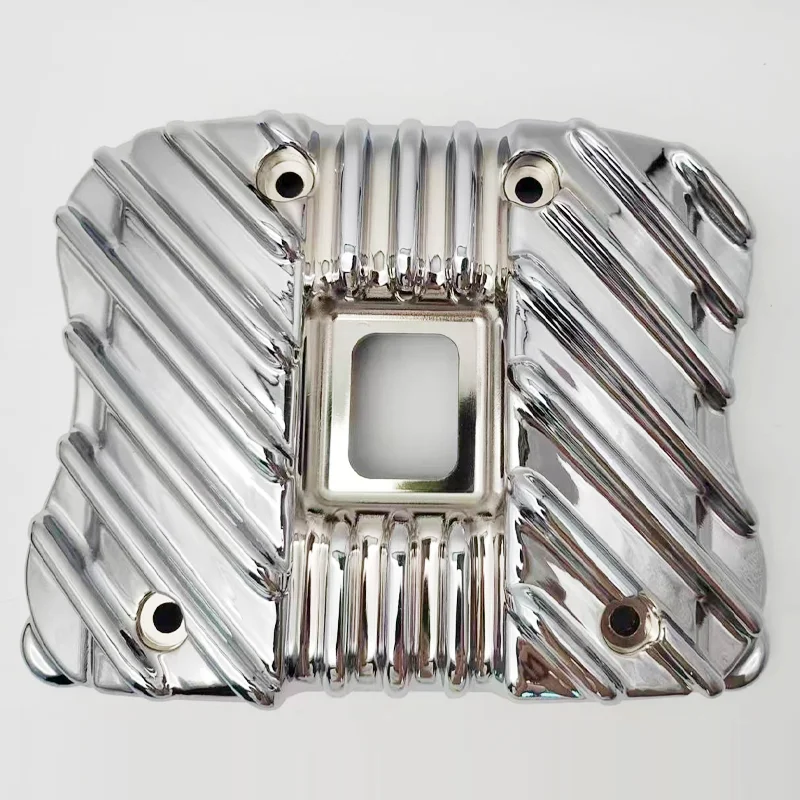

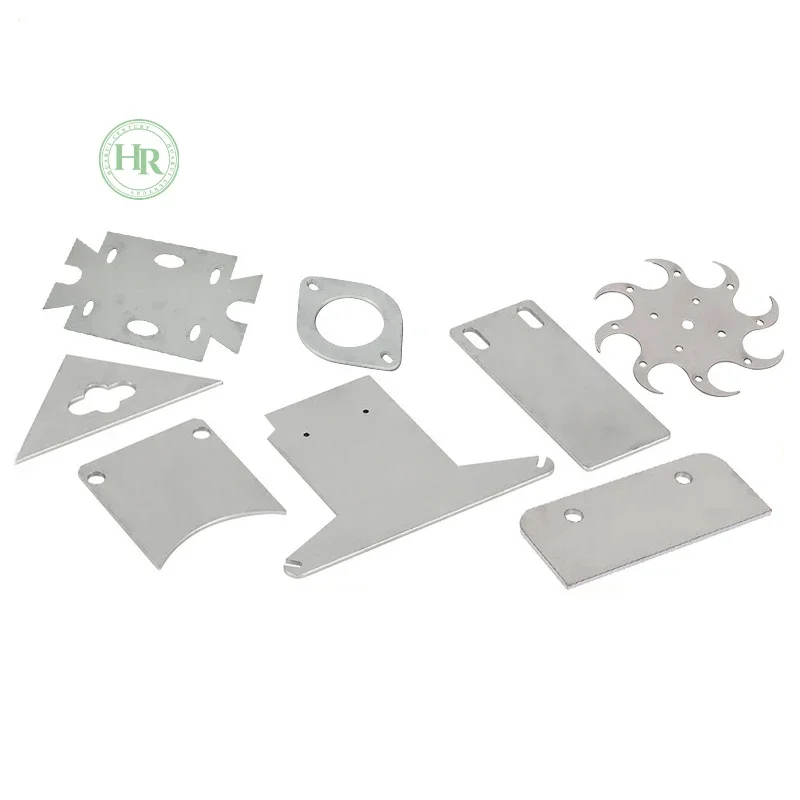

Understanding the distinct advantages of each machining process is key to optimal component design. Our CNC milling service utilizes multi-axis machines to expertly remove material from a stationary workpiece, creating intricate features, pockets, slots, and complex three-dimensional contours essential for housings, frames, and brackets. Conversely, our CNC turning service is specialized for producing axis-symmetric parts. By rotating the workpiece against a stationary cutting tool, we efficiently manufacture precise shafts, pins, bushings, and connectors. This dual-process mastery allows us to recommend the most efficient and cost-effective method for your custom CNC milling parts and CNC turning machining parts, ensuring optimal results for every unique design.

Material Expertise: Optimizing Performance with Aluminum and Stainless Steel

The selection of material directly influences the functionality, durability, and cost of a component. Our CNC milling and turning service is finely tuned to handle the specific machining characteristics of the industry's most demanded metals. For aluminum CNC turning and milling projects, we leverage its excellent machinability to deliver parts with superb finishes and tight tolerances, ideal for applications where weight reduction and heat dissipation are critical. For components demanding superior strength, corrosion resistance, and durability, our stainless steel CNC machining service employs appropriate tooling and techniques to overcome work-hardening challenges, producing clean, burr-free parts that stand up to harsh environments. This focused expertise in both aluminum and stainless steel ensures your parts are not just made, but engineered for performance.

From Digital Design to Finished Part: Our Seamless Workflow

We pride ourselves on being more than just a machine shop; we are a comprehensive manufacturing partner. Our one-stop processing capability begins with your design. Our engineering team seamlessly works with all major drawing formats to conduct a thorough review for manufacturability. The journey then moves to our production floor, where your CNC turning machining parts and custom CNC milling parts are fabricated. We integrate ancillary processes like drilling, grinding, and EDM wire cutting in-house to complete complex features. Finally, we offer a variety of surface treatment options to enhance aesthetics, corrosion resistance, or wear properties. This vertical integration translates to faster turnaround times, reduced logistical complexity, and single-point accountability for your entire project, a hallmark of a reliable production partner.

The Science of Accuracy: How We Guarantee +/-0.01mm Tolerance

Precision is a promise we back with rigorous science. Our commitment to achieving and verifying tolerances as tight as +/-0.01mm is embedded in our quality assurance ecosystem. Before machining begins, processes are meticulously planned and simulated. During production, skilled machinists monitor operations. The final and most critical step involves our arsenal of testing equipment. Every batch of CNC turning machining parts and custom CNC milling parts is subjected to 100% inspection. We utilize Coordinate Measuring Machines (CMM) for definitive dimensional analysis, toolmaker's microscopes for detailed feature inspection, and surface roughness testers. This data is compiled into a quality inspection form that accompanies your shipment, providing transparent, documented proof of conformity and giving you complete confidence in the components you receive.

Empowering Diverse Industries with Precision Components

The versatility of our CNC milling and turning service makes it a cornerstone for innovation across multiple sectors. In the automotive and transportation industry, we produce durable engine components, sensor mounts, and transmission parts from both aluminum and stainless steel. Manufacturers of industrial machinery rely on us for high-strength, wear-resistant CNC turning machining parts like rollers, gears, and hydraulic fittings. The electronics sector utilizes our precision for creating enclosures, heat sinks, and connectors that require the excellent conductivity of aluminum CNC turning and milling. From prototypes that test a new concept to high-volume production runs, our scalable and precise manufacturing services help bring robust and reliable products to the global market.

Partner with a Manufacturer Committed to Your Success

Starting a project with us is straightforward and designed to minimize your risk. We understand the need for validation, which is why we support low-volume and prototype orders. Our team is ready to provide expert feedback on your designs to optimize for manufacturability and cost. As a manufacturer with ISO 9001 certification and years of experience, we blend technical proficiency with attentive customer service. If you are looking for a dependable source for high-quality custom CNC milling parts or CNC turning machining parts in aluminum or stainless steel, contact our sales team today. Submit your drawings for a prompt and competitive quotation, and discover how our manufacturing precision in China can become a key advantage for your supply chain.