| Material: | Iron,Zn Alloy,Aluminum Alloy,Stainless steel,Aluminum | |||||||

| Process: | Die casting,lathe,spring,cnc,stamping | |||||||

| OEM: | Available | |||||||

| MOQ: | 1Pcs | |||||||

| Mass lead time: | 15-20Days | |||||||

| Sample time: | 3-7Days | |||||||

| Payment terms: | T/T, L/C, Money Gram, PayPal, Crash, Western Union | |||||||

| Country of origin: | Shenzhen, China | |||||||

FAQ

Q: Does your company belong to a manufacturing company or a trading company?

A: We are industrial component manufacturing company.

Q: What is your company's R / D ability?

A: We have a 10-persons R&D department responding for the design of a mold or production technology

Q: What is the quality control of your company?

A: Our company has the system certification of ISO9001 and IATF16949. We have special product laboratory and measurement room, and have very professional testing & measuring equipment. We do raw material incoming inspection, in-process product quality control and outgoing goods quality control.

Q: How long will the quotation be completed normally in your company?

A: According to different products, consider whether the common materials used and how the processing precision, and in general,the quotation will be completed in 1-2 days.

Q: What is lead time for goods delivery normally?

A: Depends on different product type, the delivery lead time will be 5 to 15 days normally after PO confirmed.

Product Overview

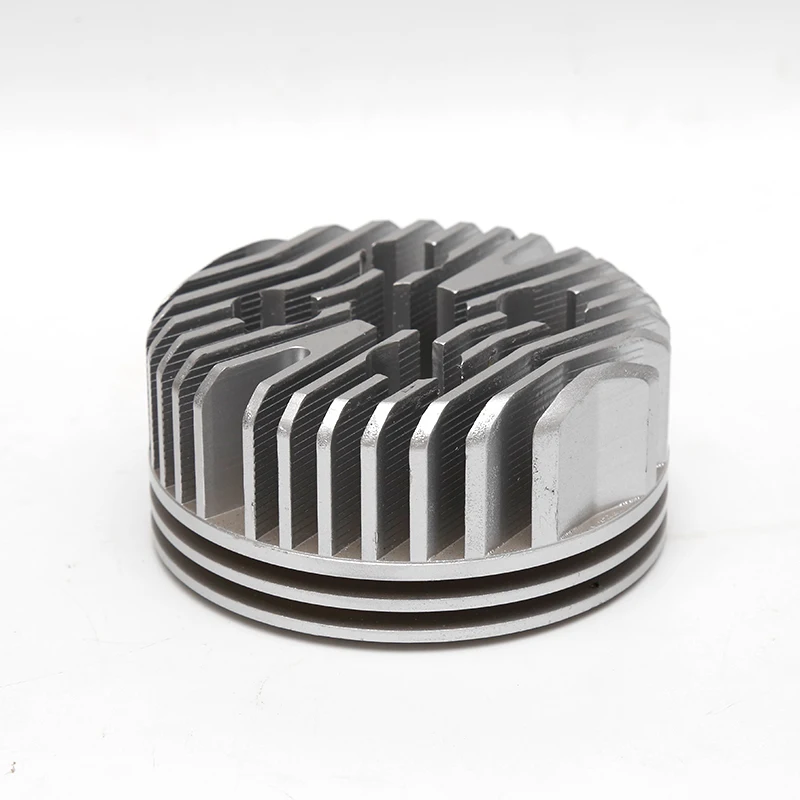

Shenzhen Huarui Century Technology Co., Ltd. is a leading manufacturer specializing in high-precision aluminum die casting parts. Our factory provides free sample services and OEM solutions tailored to meet the diverse needs of industrial, automotive, and consumer electronics sectors. With decades of experience in die casting, sand casting, and investment casting, we deliver reliable, durable, and complex components that meet strict quality standards.

-

Precision Manufacturing: We utilize advanced die casting machines and processes to produce parts with excellent dimensional accuracy and consistent performance. Complex 3D geometries, including threads, ribs, grooves, and integrated inserts, are accurately reproduced in each casting.

-

High-Quality Surface Finish: Our aluminum die castings achieve a surface roughness from Ra1.6 to Ra3.2μm. Additional finishing such as polishing, plating, or anodizing is available according to customer requirements.

-

Versatile Applications: Our parts are widely used in automotive components such as engine and transmission housings, industrial machinery, hydraulic pumps, marine hardware, and consumer electronics, including housings and heat-dissipating structures.

-

Customizable OEM Services: We support fully customized manufacturing based on customer-provided 3D drawings or CAD files. Every casting can be tailored for surface treatment, weight, size, and structural requirements to meet specific industrial applications.

Through a combination of advanced casting technology, rigorous quality control, and OEM flexibility, we deliver cost-effective, high-performance aluminum die cast components suitable for both prototypes and large-scale production.

Product Advantages

Shenzhen Huarui Century Technology Co., Ltd. leverages innovative die casting technology to provide three key advantages for aluminum components:

High Efficiency with Advanced Automation

Our factory employs fully automated die casting production lines that allow for rapid, large-volume manufacturing. Automated operations reduce labor costs and human error while maintaining consistent quality for each batch. High-speed injection and precision temperature control ensure that even complex parts are produced efficiently and within tight tolerances.

Thin-Wall Precision and Structural Integration

We specialize in producing thin-wall aluminum components, with wall thicknesses reaching as low as 1.2mm. This capability allows for lightweight yet structurally robust parts, ideal for automotive and electronics applications. The process also enables the integration of complex features such as threads, ribs, grooves, and inserts, reducing the need for secondary assembly and improving overall product functionality.

Superior Mechanical Strength and Fine Surface Detail

Aluminum die castings produced at Huarui possess dense internal structures with high mechanical strength. Rapid solidification and high-pressure injection prevent porosity while maintaining dimensional stability. Our process allows for high-detail reproduction, including logos, surface textures, and heat-dissipating features, suitable for both functional and aesthetic applications.

Production Process

The production of our high-quality aluminum die cast parts follows a structured and meticulous workflow:

-

Design & Engineering: Customer 3D drawings or CAD files are analyzed to optimize mold design. Modern simulation software is used to evaluate metal flow, cooling rates, and venting, minimizing defects and ensuring high precision.

-

Mold Fabrication: High-precision steel molds are manufactured using CNC machining, EDM, and finishing processes. Molds are designed for high durability, capable of producing tens of thousands of cycles for large-scale production.

-

Casting: Molten aluminum is injected into molds under high pressure, using either cold-chamber or hot-chamber die casting depending on alloy selection. The process ensures accurate replication of complex geometries.

-

Post-Processing: After casting, parts are trimmed, deburred, and subjected to surface treatments including polishing, anodizing, plating, or sandblasting, meeting specific functional and aesthetic requirements.

-

Quality Control: Each part undergoes strict inspection including chemical composition analysis, CMM measurement, X-ray radiography, and visual examination to ensure compliance with customer specifications.

-

Packaging & Delivery: Finished parts are carefully packaged to prevent damage and shipped according to customer logistics requirements, ensuring safe and timely delivery.

This workflow guarantees high-quality, dimensionally accurate, and cost-effective production suitable for both prototype and mass-production projects.

Product Parameters

| Parameter | Specification / Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HUARUI |

| Model Number | HR |

| Product Name | Die Casting Part, Sand Casting, Investment Casting |

| Process | Casting, Deburring, Drilling, Threading |

| Certification | ISO9001, TS16949 |

| Service | Customized OEM, Free Sample |

| Size | According to Customer's 3D Drawing |

| Surface Treatment | Customized; Heat Treatment, Polishing, Plating, Machining, Shot/Sand Blasting, Zinc Plating, E-Coating |

| Tolerance | Customer Drawing Request |

| Standard | Client Specification, ISO, DIN, AISI, ASTM, BS, JIS |

| Color | Customized |

| Quality Control | 100% Strict Inspection |

| Surface Finish | Ra1.6 – Ra3.2 μm |

| Maximum Size | ≤1200mm × 800mm × 400mm |

| Weight Range | 0.1 – 120 kg |

| Materials | Aluminum Alloy, Stainless Steel, Carbon Steel, Alloy Steel, Brass, Aluminum Bronze |

| Applications | Automotive, Industrial Machinery, Valves, Pumps, Electronics, Marine Hardware, Construction, Consumer Devices |

| Inspection Methods | Spectrum Analysis, Magnetic Particle Inspection, Cleanliness Inspection, X-Ray Radiography, CMM Measurement |

Buyer Engagement Guidance

Shenzhen Huarui Century Technology Co., Ltd. invites businesses and engineers to request free samples and personalized quotations for high-quality aluminum die cast parts. Submit your 3D drawings or specifications to explore our OEM solutions, competitive pricing, and fast production schedules. Our team ensures responsive communication and tailored manufacturing support for your precise project requirements.

Contact us today to experience our reliable, efficient, and cost-effective die casting services.

FAQ

Q1: What materials do you provide for die casting?

A1: We cast aluminum alloys, brass, aluminum bronze, stainless steel, carbon steel, and other alloys depending on project requirements.

Q2: What is the maximum size of a casting?

A2: Maximum casting dimensions are 1200mm × 800mm × 400mm.

Q3: Can you produce thin-wall components?

A3: Yes, aluminum components can be cast with a minimum wall thickness of 1.2mm.

Q4: What surface finishes are available?

A4: Surface finishes range from Ra1.6 to Ra3.2 μm. Additional treatments include polishing, plating, anodizing, sandblasting, and e-coating.

Q5: Do you support OEM and free sample requests?

A5: Yes. We provide customized OEM production and free samples to support testing and validation before mass production.

Q6: How do you ensure quality control?

A6: All parts are subject to strict inspection, including chemical analysis, CMM measurement, X-ray radiography, and visual checks for dimensional accuracy and defect detection.