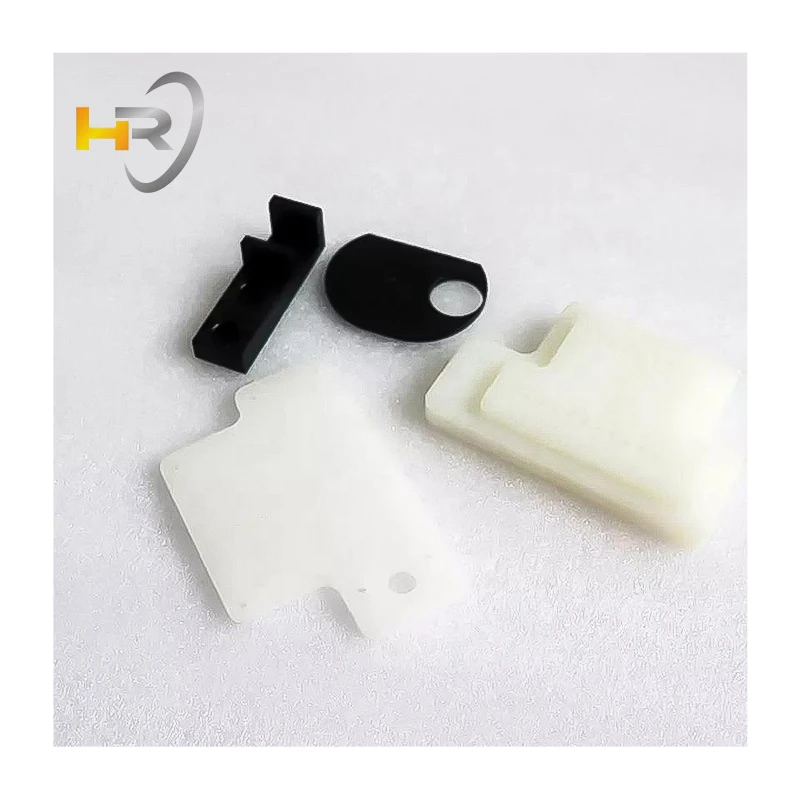

Custom metal fabrication deep drawn sheet metal precision stainless steel stamping enclosure parts

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

| Material: | Iron,Zn Alloy,Aluminum Alloy,Stainless steel,Aluminum | |||||||

| Process: | Die casting,lathe,spring,cnc,stamping | |||||||

| OEM: | Available | |||||||

| MOQ: | 1Pcs | |||||||

| Mass lead time: | 15-20Days | |||||||

| Sample time: | 3-7Days | |||||||

| Payment terms: | T/T, L/C, Money Gram, PayPal, Crash, Western Union | |||||||

| Country of origin: | Shenzhen, China | |||||||

Product Overview

Comprehensive Introduction

Our custom metal fabrication deep drawn sheet metal precision stainless steel stamping enclosure parts are engineered for demanding industrial applications where accuracy, structural integrity, and consistency are essential. Manufactured using advanced deep drawing and high-precision stamping technologies, these enclosure components deliver high mechanical strength without compromising on dimensional precision. They are widely used in electronics housings, automotive structural parts, medical devices, industrial control enclosures, communication modules, and many other sectors that require durable and lightweight protective solutions.

Product Performance

-

High structural rigidity achieved through continuous material flow during deep drawing.

-

Excellent corrosion resistance with stainless steel grades such as SS304, SS316, and optional plated coatings.

-

Tight dimensional tolerance and repeatability ensured by high-precision molds and automated production lines.

-

Smooth surface quality determined by mold profile, supporting post-finishing such as polishing, powder coating, and plating.

-

Lightweight design with enhanced deformation resistance, suitable for portable or space-constrained equipment.

Our facility supports prototyping to mass production, ensuring every stamped enclosure part meets strict international quality standards, while fulfilling diverse customization requirements.

Product Advantages

Enhanced Dimensional Stability via Mold-Based Processing

The stamping molds are designed with advanced surface simulation and high-precision tooling manufacturing technologies. Once the mold enters stable production, each part maintains identical dimensions and mechanical performance. This inherent consistency reduces product variation, improves assembly efficiency, and ensures perfect interchangeability of mass-produced enclosure parts.

One-Time Forming for Complex Geometries

Deep drawing allows complex three-dimensional shapes such as cylindrical bodies, stepped structures, ribs, flanges, and reinforced corners to be formed in a single cycle. It eliminates multiple welding and bending operations common in traditional sheet fabrication, reducing part count and cumulative tolerances. This capability is particularly beneficial for waterproof sealed enclosures, automotive housings, and precision mechanical assemblies requiring superior structural continuity.

Ultra-Fast Cycle Time for Large-Scale Manufacturing

High-speed stamping presses support efficient automated production, enabling extremely short forming cycles per enclosure part. This results in:

-

Reduced per-piece cost in large batch orders

-

Higher throughput to meet time-critical delivery needs

-

Scalable production capacity from tens of thousands up to millions of units annually

The process is highly competitive for products with long life cycles and high-volume market demand, such as consumer electronics and household appliances.

Production Process

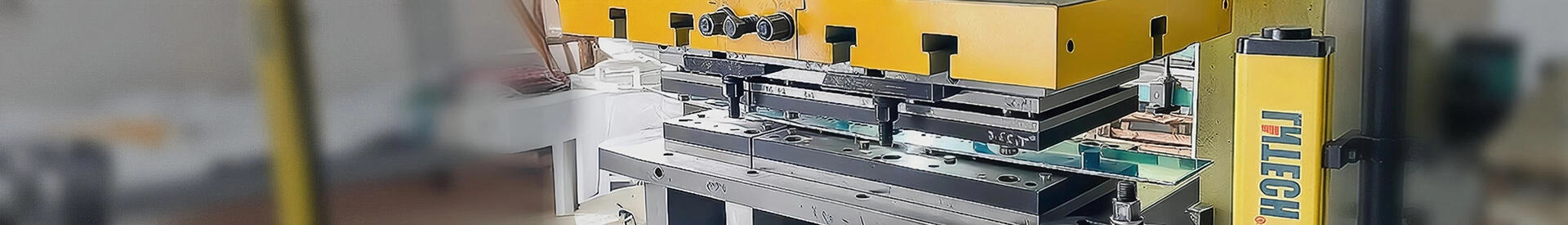

Fully Controlled, Automated Manufacturing Workflow

We adopt a robust and traceable production process to ensure quality, efficiency, and stability at every step:

-

Material Selection

-

Stainless steel, aluminum, carbon steel, copper, and plated sheet options

-

Thickness from ultra-thin foils to 6 mm sheets depending on enclosure structure requirements

-

-

Mold Design and Engineering Simulation

-

CAE forming analysis to minimize springback, wrinkling, and cracking risks

-

Surface texture and tooling geometry optimized for precise enclosure contours

-

-

Stamping and Deep Drawing Operations

-

Combined forming process including punching, blanking, bending, flanging, rib forming, and precision deep drawing

-

Automated feeding and monitoring for stable production rhythms

-

-

Secondary Functional Processing

-

Laser cutting, CNC machining, spot welding, riveting, tapping, and inserts installation when required

-

-

Surface Treatment

-

Optional finishing: brushing, anodizing, powder coating, passivation, or EMI shielding coating

-

-

Quality Control and Inspection

-

In-process SPC, CMM measurement, burr-free assurance, visual inspection, and performance validation

-

-

Protective Packaging and Global Shipment

-

International compliant export packaging for safe long-distance transport

-

This process ensures world-class product integrity from raw material to finished enclosure parts.

Inquiry Contact Encouragement

We welcome OEM/ODM projects of any complexity.

To receive a precise quotation, kindly share:

-

Technical drawings (STEP, IGES, PDF)

-

Material and thickness requirements

-

Surface finishing requirements

-

Estimated annual production volume

-

Functional requirements such as IP rating or EMI shielding

Our engineering and sales teams will provide cost-effective solutions, mold design recommendations, and rapid manufacturability feedback within 24 hours.

Contact us now to accelerate your product launch and maintain a competitive manufacturing advantage.

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity for stamped enclosure parts?

A: We support flexible MOQ depending on material and tooling requirements. Prototype batches are available before mass production.

Q2: Can you assist in product optimization before mold development?

A: Yes. We offer DFM analysis, structural optimization, and cost-down advice based on stamping feasibility studies.

Q3: What quality standards do you follow?

A: Our production adheres to ISO 9001 quality systems, full inspection records, and traceability throughout manufacturing.

Q4: How long does mold manufacturing take?

A: Standard deep drawing molds typically require 3–6 weeks depending on complexity and number of forming stations.

Q5: Do you provide material certifications and test reports?

A: Yes. Material composition, RoHS/REACH compliance, and mechanical test reports can be supplied upon request.

Q6: What industries do you mainly serve?

A: Automotive, drones, electronics, 5G communications, lithium-battery systems, household appliances, medical devices, and industrial automation.