Micro Porous Titanium Parts Non-Standard Small CNC Passivation Service

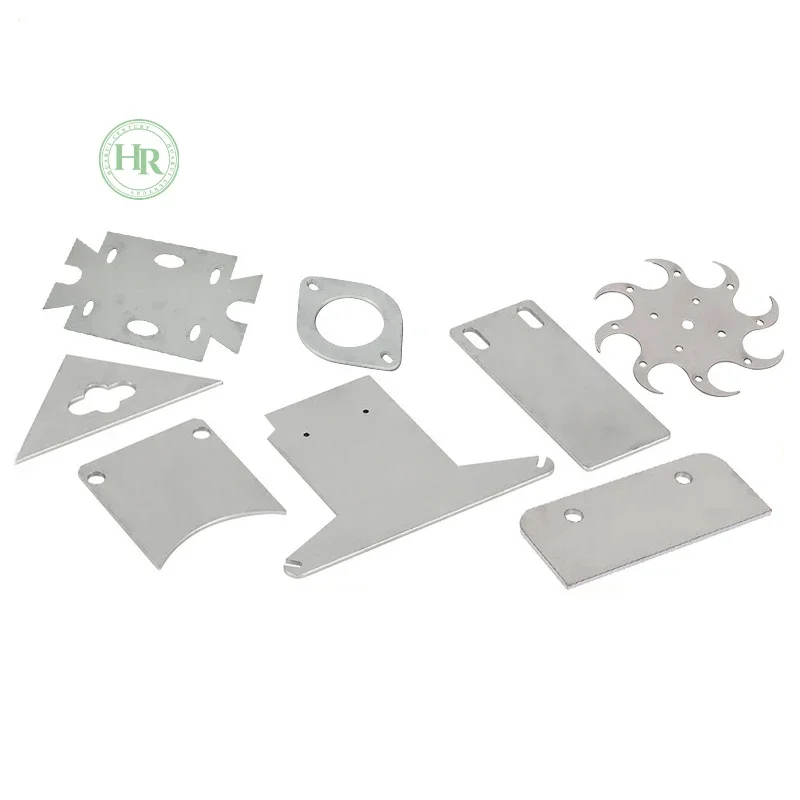

Specializing in the precision manufacturing of non-standard, porous, and miniature titanium and stainless steel components. Our service masters the challenges of micro-CNC machining to create complex small parts with high-density pore structures, channels, or fine features. We integrate critical biocompatible surface treatments like passivation and electropolishing to meet medical and high-tech industry standards. To validate our quality and capability, we provide functional samples for your testing and approval. Ideal for medical implants, filtration systems, and advanced instrumentation where precision, material integrity, and surface compatibility are non-negotiable.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

In domains where innovation is measured in microns and performance hinges on microscopic structures, conventional manufacturing reaches its limits. The creation of non-standard, porous, and exceptionally small titanium and stainless steel parts represents one of the most demanding challenges in precision engineering. Our dedicated service exists to meet this challenge head-on. We are specialists in micro-CNC machining and advanced processing, focused on producing components where features are miniaturized, geometries are intrinsically porous, and applications demand the material excellence of titanium or the corrosion-resistant reliability of stainless steel. When your project involves such critical small CNC parts, partnering with a specialist is not a luxury—it is a necessity for success.

Engineering at the Micro Scale: The Art and Science of Small Parts Machining

Machining parts deemed "small" or "miniature" requires a fundamental shift in approach. When features approach or fall below one millimeter, forces like tool deflection, vibration, and heat management become exponentially more critical. Our expertise in small CNC parts machining is built on a foundation of specialized technology and refined technique. We utilize high-precision, high-speed CNC machining centers equipped with micro-tooling capable of creating intricate details with exceptional accuracy. The process involves meticulously calculated cutting parameters, often employing advanced cooling strategies to protect the delicate tools and the workpiece integrity of materials like grade 5 titanium or 316L stainless steel. This command over the micro-scale ensures we can hold tight tolerances, even on the most diminutive non-standard porous titanium parts, transforming complex digital designs into flawless physical realities.

The Architecture of Porosity: Designing and Manufacturing Controlled Porous Structures

Porosity is not a flaw; it is a designed-in engineering feature with profound functional benefits, from bone ingrowth in implants to fluid distribution in filters. Manufacturing these controlled porous structures, especially in hard metals like titanium, is a core competency. We employ sophisticated CNC machining strategies to create precise patterns of pores, channels, and lattice networks. This can involve meticulous micro-drilling arrays, intricate milling of interconnected channels, or the use of specialized techniques for stochastic porosity. For non-standard porous small titanium parts, every aspect—pore size, shape, distribution, and interconnectivity—is executed according to your specifications. This capability allows for the engineering of specific permeability, surface area, and mechanical properties directly into the component, enabling breakthroughs in lightweight design and biological integration.

Beyond Machining: The Critical Role of Surface Finishing and Passivation

For components destined for medical, aerospace, or high-purity applications, machining is only part of the journey. The surface condition is paramount. This is where our passivation service becomes indispensable. For stainless steel parts, passivation is a controlled chemical process that removes free iron contaminants and enhances the natural chromium oxide layer, dramatically improving corrosion resistance. For titanium parts, a similar process ensures a uniform, inert, and bio-inert surface. We also offer electropolishing for a superior, ultra-clean finish that further minimizes adhesion and improves cleanability. These are not mere aesthetic steps; they are functional treatments that ensure the long-term performance, safety, and compliance of your non-standard parts in critical environments. Our in-house control over these processes guarantees consistency and quality from bulk material to finished component.

From Concept to Confidence: Our Sample-Driven Validation Process

We understand that adopting a new supplier for critical, non-standard components involves significant technical and financial risk. This is why we emphasize our ability to send samples. Our "Can Send Samples" policy is a cornerstone of our partnership approach. It allows you to physically evaluate the precision of our small CNC parts, test the functionality of a porous structure, and verify the quality of our passivation service before committing to full-scale production. The sample you receive is a testament to our entire process—from design review and micro-machining to final cleaning and packaging. It serves as tangible proof of our capability, enabling you to make an informed decision with confidence. This commitment to transparency and verification is what builds lasting trust in high-stakes manufacturing partnerships.

Applications Where the Minute Details Matter Most

Our capabilities serve the most demanding sectors where miniature scale and complex functionality intersect. In the medical and dental fields, we manufacture porous titanium structures for orthopedic and dental implants that promote osseointegration, and precise stainless steel components for surgical instruments. For filtration and separation technology, we create intricate porous titanium and stainless steel meshes, frits, and distributor plates. The aerospace and semiconductor industries rely on us for miniature, lightweight titanium fittings and ultra-clean, passivated stainless steel fluidic components. In each case, our role is to provide not just a part, but a fully realized, application-ready solution that meets stringent regulatory and performance standards.

Why Choose a Specialist for Your Most Demanding Component Needs

Selecting a general machine shop for non-standard porous or micro-scale parts often leads to compromised designs, failed prototypes, and project delays. As specialists, we offer distinct advantages. Our entire workflow, from quoting to inspection, is tailored for complexity and scale. Our engineers speak the language of micro-design and bio-materials. Our quality control utilizes high-magnification optical inspection and specialized measurement tools to verify features invisible to the naked eye. We provide comprehensive documentation, including material certifications and surface treatment reports. By consolidating your project with us, you gain a partner with the focused expertise, appropriate technology, and rigorous processes to navigate the complexities of advanced small parts manufacturing successfully.

Begin with a Sample: Your Pathway to a Trusted Partnership

Initiating a project is designed to be a collaborative and low-risk exploration. We invite you to share your most challenging design for a non-standard porous small titanium part or a precision stainless steel component. Our technical team will conduct a thorough feasibility analysis and engage with you on optimizations for manufacturability. Based on this, we can propose a sample production run to deliver physical parts for your evaluation. This initial step allows us to align on expectations, demonstrate our expertise, and build the foundation for a reliable supply chain for your most critical components. Contact us today to discuss how our mastery of micro-scale and porous manufacturing can bring your advanced concepts to life.