Professional Custom Sand Casting & Die Casting Services for Stainless Steel and Iron Parts

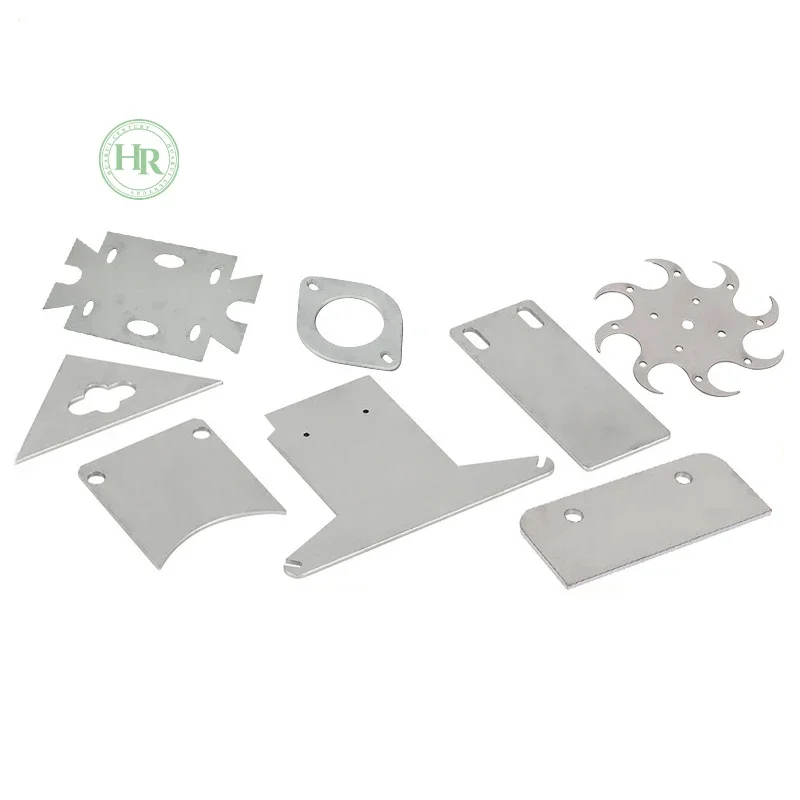

Meet your most demanding manufacturing needs with our comprehensive custom casting solutions. We specialize in both high-volume die casting for precision components and versatile sand casting for large, complex parts, utilizing materials ranging from stainless steel and iron to various aluminum, zinc, and magnesium alloys. Supported by in-house deep processing (CNC, milling, drilling) and surface finishing, we provide end-to-end OEM manufacturing for industrial fittings, construction, furniture, and decorative applications. Partner with us for reliable, high-quality cast parts delivered through a transparent and collaborative process.

Craft name |

Die casting parts service |

Mold Material |

Aluminum,SKD61,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Material |

Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . Zinc: ZA3#, ZA5#, ZA8# or customized . Magnesium: AZ91D, AM60B or customized . |

Surface Treatment |

Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Deep Processing |

CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

Application |

furniture,Industry fittings and Construction and Decoration,etc. |

Q1:What is the specific production process? |

Die designing→Die making→Smelting&alloying→QC→Die casting→remove burrs→QC→Surface treatment→QC→Packing→QC→Shipping→After Sale Service. |

Q2: How soon can I get samples? |

Depending on your specific project, it usually takes 10 to 20 days. |

Q4:Can you make machining parts based on our samples? |

Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Engineer Your Vision with Precision Casting Solutions

In the competitive landscape of industrial manufacturing, the foundation of a superior product often lies in the quality and capability of its core metal components. When standard parts fall short, a custom casting service becomes not just an option, but a strategic necessity. For engineers, procurement specialists, and business owners seeking durable, complex, and reliable metal parts, the choice of a manufacturing partner is paramount. Our dedicated custom casting service is engineered to transform your designs into robust reality, offering a dual-process approach that covers the vast spectrum of industrial needs. We stand as more than a supplier; we are your integrated manufacturing ally, committed to delivering cast parts that endure and perform.

Two Processes, One Goal: Matching Method to Mission

Understanding the distinct advantages of each casting technique is key to optimal part design and cost-efficiency. We master two foundational processes to ensure your project is built the right way from the start.

High-Pressure Die Casting: Precision at Scale

When your project demands high-volume production of components with intricate details, thin walls, and exceptional dimensional consistency, our die casting service delivers unmatched efficiency. This process forces molten metal under intense pressure into precision steel molds, producing parts with excellent surface finish and minimal need for secondary machining. It is the go-to method for creating strong, lightweight, and complex parts essential for high-cycle applications. From delicate hardware for furniture to robust housings for industrial equipment, our die casting capability ensures repeatable quality and cost-effectiveness for large production runs, making it a cornerstone of modern manufacturing.

Versatile Sand Casting: The Art of Complexity and Size

For larger components, lower volume batches, or parts with complex internal geometries that other processes cannot achieve, our sand casting service offers unparalleled flexibility. This method utilizes a custom-formed sand mold for each casting, allowing for incredible design freedom without the high cost of permanent tooling. It is the ideal solution for producing heavy-duty machine bases, large architectural components for construction and decoration, and unique prototypes. The sand casting process accommodates a wider range of ferrous metals, including various grades of iron and steel, providing the structural integrity required for the most demanding industrial environments.

The Element of Strength: Our Material Expertise

The performance of any cast part is fundamentally linked to its material composition. Our expertise spans a comprehensive selection of alloys, allowing us to recommend the perfect material to meet your functional, environmental, and budgetary requirements.

- Stainless Steel & Iron: For applications requiring superior strength, corrosion resistance, and longevity, our stainless steel and iron castings are indispensable. These materials are essential for parts exposed to harsh weather in construction, demanding loads in industrial machinery, or requiring specific aesthetic finishes in decorative applications.

- Aluminum Alloys (e.g., A360, A380): We offer various aluminum alloys prized for their excellent strength-to-weight ratio, good corrosion resistance, and thermal conductivity. These are widely used in applications where reducing weight is crucial without sacrificing durability.

- Zinc Alloys: Known for high strength, hardness, and exceptional dimensional stability, zinc alloys are perfect for thin-wall castings and intricate components that require precision, such as fittings and decorative hardware.

- Magnesium Alloys (e.g., AZ91D): As the lightest structural metal, magnesium offers an outstanding strength-to-weight ratio, ideal for applications where weight reduction is a critical factor.

Our technical team collaborates with you to select the optimal alloy, ensuring your custom casting delivers the required mechanical properties and performance.

Beyond the Cast: Integrated Manufacturing for Finished Parts

Our service commitment extends far beyond the initial casting. We operate as a vertically integrated manufacturer to deliver parts that are ready for assembly. Following the casting process, our comprehensive in-house deep processing capabilities take center stage. Our workshops are equipped for CNC machining, precision milling, drilling, and tapping. This allows us to add critical threads, precise bores, and finished surfaces directly to your casting, guaranteeing final dimensional accuracy and significantly reducing lead times by eliminating the need for multiple suppliers.

Quality assurance is integrated into every step. We maintain rigorous inspection protocols, from verifying raw material certifications to performing dimensional checks with calibrated instruments and conducting visual inspections on finished parts. As a professional manufacturer based in China, we understand the importance of transparency in global partnerships. We keep you informed throughout the production journey, providing updates to ensure you have complete confidence without needing to visit the facility.

Casting Success Across Industries: Your Applications

The components we produce are engineered to excel where reliability is non-negotiable. In the industrial fittings and machinery sector, our castings form the robust frames, gears, and durable housings that keep operations running smoothly. Within construction and decoration, we provide the structural strength and intricate detail for architectural hardware, custom facades, and heavy-duty support elements that blend durability with design. For the furniture industry, particularly for high-end commercial or outdoor settings, we supply solid and reliable cast parts for joints, bases, and mechanisms that combine aesthetic appeal with long-lasting performance.

This wide applicability is a direct result of our ability to tailor both the casting process and material science to the specific challenge. By choosing our custom casting service, you gain access to application-specific engineering support, ensuring the final component is a perfect fit for its intended role.

Initiating Your Custom Casting Project

Starting a project with us is a streamlined and collaborative process designed for clarity and efficiency. It begins with your design, which we accept in all major industry-standard drawing formats (IGES, STEP, Solidworks, DWG, etc.). Our engineering team then conducts a thorough design-for-manufacturability review, offering insights that can optimize your part for casting, potentially saving time and reducing costs.

We are a reliable manufacturing partner dedicated to building long-term relationships. Our sales and engineering teams are focused on understanding your precise needs and delivering high-quality, dependable casting solutions. We invite you to experience the advantage of working with a focused and capable foundry partner. Contact us today to discuss your specific requirements for stainless steel castings, iron parts, or any custom metal component, and let us provide you with a detailed quote for your high-quality parts.