Metal Fabrication Stainless Steel Bending Stamping Sheet Metal Mechanical Parts Custom Small Precision Brass Stamping Parts

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

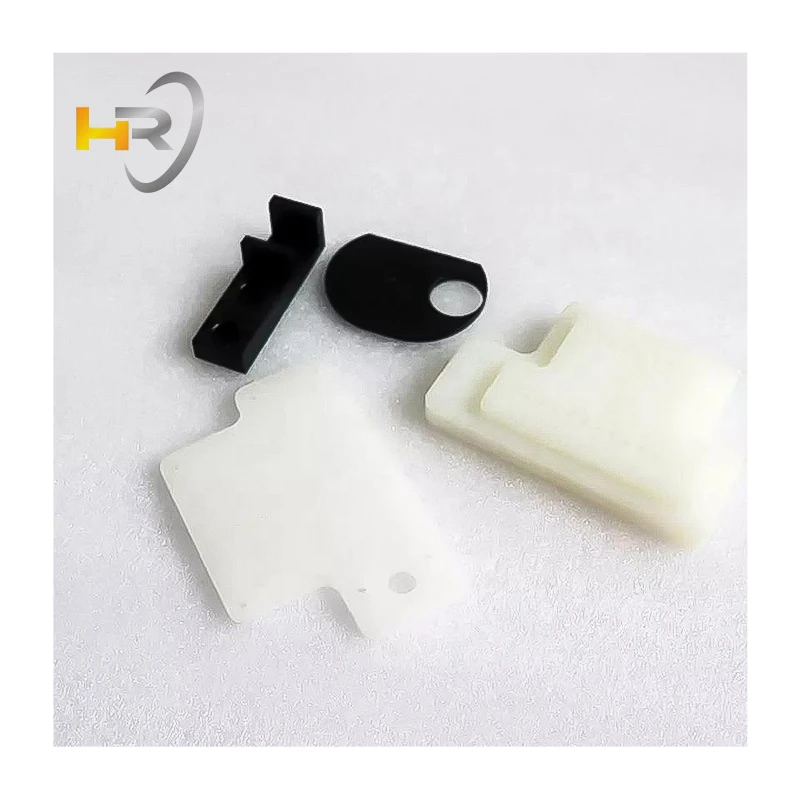

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Name |

custom manufacturing sheet metal fabrication parts service |

Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Processing |

Stamping ,Sheet metal fabrication |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Our Advantages |

1.) 24 hours online service & Quickly Quote/Delivery. 2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) To provide production design, production and technical service, mould development and processing, etc |

You are very welcome to visit us among many suppliers

2.) 24 hours online service & Quickly Quote

3.) We have very rich experience, you are welcome to discuss with us at any time your requirements or products that you need to customize.

4.) 100% QC quality inspection before delivery, and can provide quality inspection form.

5.) Our products and services have been widely praised by customers at home and abroad

6.) ISO certificate Factory

7.)In order to allow you to receive goods more quickly and conveniently, we support sea, land, express and air transportation

Product Overview

Product Introduction

Shenzhen Huarui Century Technology Co., Ltd. specializes in high-quality metal fabrication, providing precision stainless steel bending, stamping, and small brass parts manufacturing for a wide range of industries. Our capabilities cover mechanical components, enclosures, brackets, clips, and functional assemblies that require tight tolerances, high repeatability, and reliable performance.

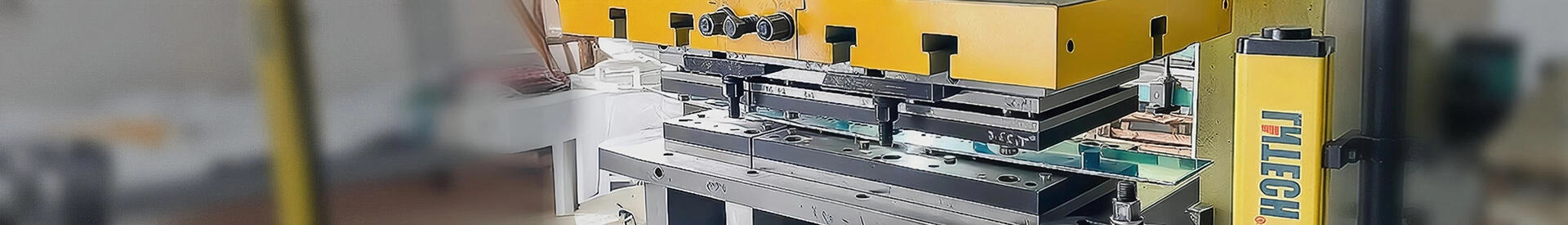

We integrate modern stamping techniques with advanced bending and forming technologies to create precise sheet metal products. Using state-of-the-art CNC presses and high-precision tooling, our production lines handle stainless steel, low-carbon steel, aluminum, and brass sheets, ranging from ultra-thin foils to medium-thickness plates (typically ≤6mm).

Product Performance Attributes

-

High Dimensional Accuracy: Each part is produced with strict control over tolerances, ensuring consistency across large production runs.

-

Superior Mechanical Properties: Deep drawn and stamped components maintain structural integrity, high strength, and optimal internal grain flow, suitable for functional applications in automotive, electronics, and industrial machinery.

-

Customizability: We accommodate complex geometries, including flanges, ribs, hems, and folded edges, without the need for post-welding, enhancing efficiency and reducing assembly costs.

-

Surface Quality and Finishing: Parts retain smooth surfaces determined by mold precision, suitable for subsequent treatments such as polishing, passivation, plating, or coating.

-

Scalability: Our production solutions support prototype validation, small batch customization, and high-volume manufacturing, providing flexible service for diverse customer needs.

Our solutions are widely adopted in industries requiring reliable, repeatable, and high-precision components, from miniature brass parts to stainless steel enclosures, ensuring functional integrity and cost-effective production.

Product Advantages

1. High Production Efficiency with Integrated Operations

Our manufacturing lines integrate stamping, bending, and forming processes into a continuous workflow, achieving high production rates and reduced cycle times. By combining progressive dies with automated feeding systems, we enable mass production with minimal operator intervention. This ensures that large-scale orders are fulfilled quickly, meeting demanding deadlines without compromising quality.

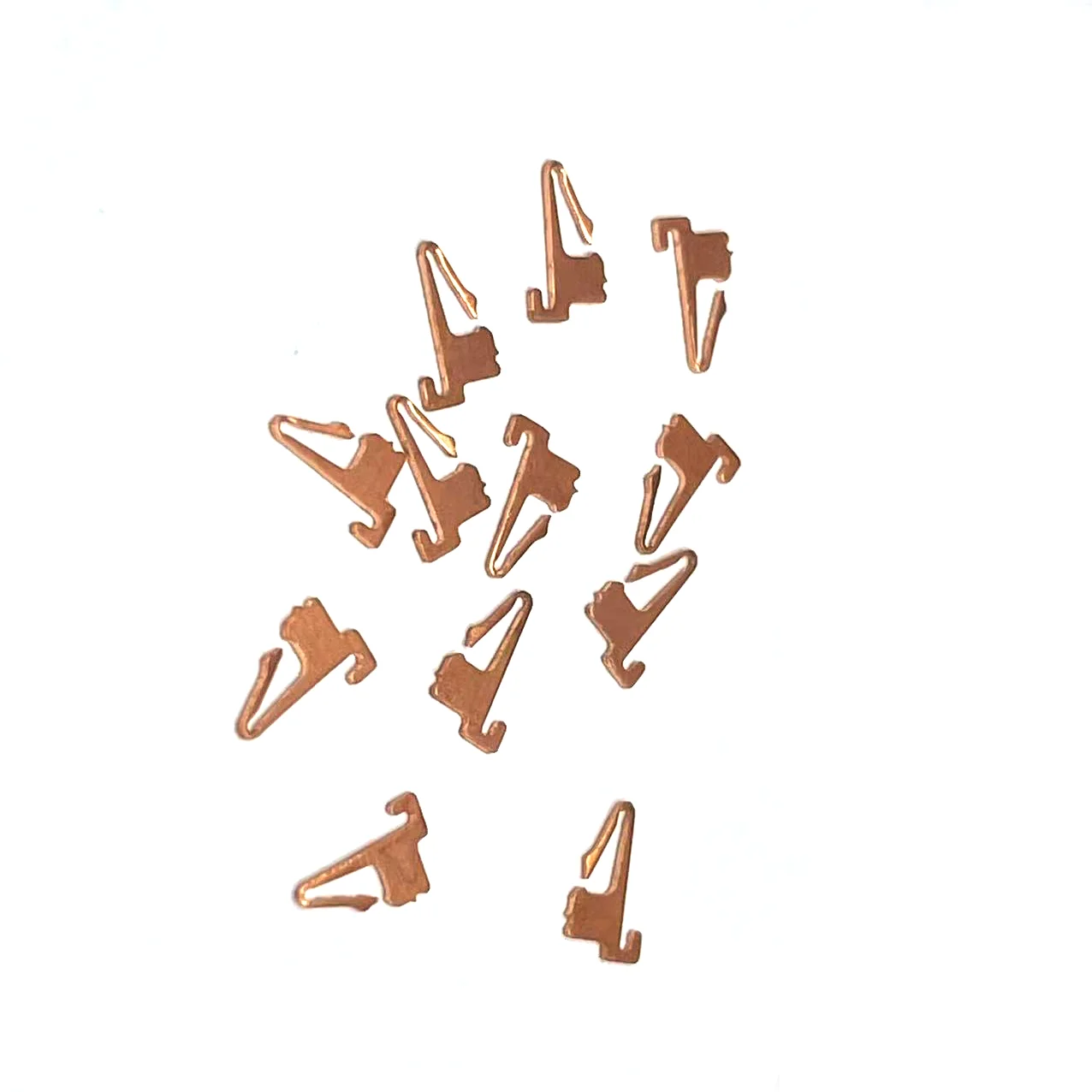

2. Capability to Produce Small and Precision Components

Our equipment supports micro-stamping and precision metal forming, allowing the production of small mechanical parts, brass contacts, and fine sheet metal features with excellent repeatability. This is critical for electronics, connectors, and precision assemblies where dimensional accuracy and functional performance are paramount. Our precision tooling ensures minimal burr formation and consistent tolerances even for miniature geometries.

3. Cost Efficiency and Material Optimization

Through optimized nesting layouts, progressive die usage, and reduced scrap, we maximize raw material utilization, lowering production costs while maintaining high quality. This approach is particularly advantageous for medium to high-volume runs of stainless steel or brass components. Additionally, by minimizing post-processing requirements, we reduce labor and overhead expenses, delivering cost-effective solutions without sacrificing performance.

These advantages make our metal fabrication services suitable for complex industrial components, small precision assemblies, and high-volume manufacturing, offering reliability, consistency, and economic efficiency for our customers.

Production Process

Streamlined Manufacturing Workflow

Our metal stamping and bending operations follow a structured process designed to ensure quality, repeatability, and efficiency:

-

Design Review and Feasibility Analysis

Customers submit technical drawings, material specifications, and functional requirements. Our engineers assess manufacturability and suggest optimizations to improve part performance and reduce production risks. -

Tooling and Mold Development

Custom dies are designed and simulated to ensure minimal springback, accurate dimensional control, and precise feature formation. Mold testing verifies surface finish, strength, and functional geometry. -

Pilot Run and Sample Inspection

Initial production samples are inspected using coordinate measuring machines (CMM) and visual examination. Tolerances, dimensions, and surface quality are verified before full-scale production. -

Mass Production with Automated Lines

Progressive stamping lines, robotic material handling, and inline quality checks allow high-volume production while maintaining consistent performance. Production parameters, including press tonnage, stroke speed, and lubrication, are continuously monitored. -

Finishing and Post-Processing

Value-added services such as deburring, polishing, passivation, plating, and assembly integration are available. Each step is optimized to preserve material properties and enhance component performance. -

Final Inspection, Packaging, and Shipping

Every batch undergoes rigorous quality verification to ensure compliance with customer specifications. Packaging adheres to international standards to prevent damage during transport.

This workflow ensures full traceability, high-quality output, and consistent delivery performance for small precision brass components and stainless steel sheet metal parts.

Buyer Inquiry Instructions

To help us provide precise solutions tailored to your needs, please submit:

-

CAD or technical drawings (STEP, IGES, PDF)

-

Material type and thickness

-

Required surface finish or post-processing

-

Functional requirements or tolerance specifications

-

Estimated order volume and production frequency

Our technical team will review your request promptly, providing professional recommendations, competitive quotations, and guidance on design adjustments for manufacturability and cost efficiency. Contact us today to secure high-quality metal fabrication services tailored to your exact specifications.

Frequently Asked Questions (FAQ)

Q1: What materials can you process for stamping and bending?

We work with stainless steel, brass, aluminum, low-carbon steel, copper, and coated or plated sheets.

Q2: Can you handle complex three-dimensional shapes?

Yes. Our tooling and progressive die systems enable forming of flanges, ribs, hems, and deep-drawn features with high precision.

Q3: What is the minimum feature size achievable for small precision parts?

Our micro-stamping capabilities allow features as small as 0.5 mm, depending on material thickness and type.

Q4: How do you ensure repeatability in high-volume production?

We utilize automated stamping lines, inline inspection, and precise die maintenance schedules to maintain tight tolerances throughout long production runs.

Q5: Can you provide prototypes before full-scale production?

Absolutely. Prototyping ensures design feasibility, functional verification, and assembly fit before committing to tooling investment.

Q6: Do you offer surface finishing options?

Yes. Options include polishing, passivation, plating, powder coating, anodizing, and other treatments tailored to application requirements.

Q7: Are you able to support international shipping?

Yes. We provide reliable global logistics and export-ready packaging to ensure safe delivery of your components worldwide.

Q8: What is the typical lead time for production?

Lead time depends on tooling complexity and order volume. Standard small-to-medium batch production generally ranges from 3 to 6 weeks.

Q9: Can you handle design modifications after production starts?

Design changes after tooling production may require die modification, potentially increasing costs. We recommend confirming final designs during prototype validation.