Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. offers Hot Sale Factory Direct Live Tooling Lathe CNC Full Functional CNC Lathe Parts, designed to meet the highest precision and performance standards for industrial and high-tech applications. With years of experience in CNC machining, we specialize in delivering customized solutions that cover a wide range of materials, including stainless steel, aluminum, and titanium.

-

Advanced Live Tooling Capability: Our CNC lathes are equipped with live tooling systems, enabling complex operations such as milling, drilling, and threading directly on the lathe spindle without removing the workpiece. This reduces setup times and ensures superior precision and consistency.

-

High-Precision Machining: Using both 4-axis and 5-axis CNC capabilities, we can produce components with intricate geometries and tight tolerances, suitable for aerospace, automotive, medical, and high-performance sporting applications.

-

Material Flexibility: We handle a diverse range of metals and alloys, including titanium, stainless steel, aluminum, brass, bronze, and copper, allowing clients to select materials that meet specific mechanical, thermal, or corrosion resistance requirements.

-

Micro and Standard Machining: Our machining services accommodate both delicate micro components and larger industrial parts, ensuring versatile solutions for small-scale prototypes or full production batches.

-

OEM/ODM Support: From concept to full-scale production, our team supports OEM and ODM orders, offering private-label manufacturing and complete customization tailored to client specifications.

Every component is rigorously inspected to ensure compliance with stringent quality standards, providing clients with durable, high-performance lathe parts optimized for demanding industrial environments.

Key Product Advantages

Titanium Parts: Exceptional Strength-to-Weight Ratio

Titanium parts produced in our live tooling lathes offer an outstanding strength-to-weight ratio, making them ideal for applications where reducing mass without compromising durability is critical. This property is particularly valuable in aerospace structural components, high-performance engines, and premium cycling frames. By minimizing weight while maintaining structural integrity, titanium components enhance overall system efficiency and reliability.

Superior Corrosion Resistance in Harsh Environments

Our CNC-machined titanium and stainless steel parts are engineered for excellent corrosion resistance, especially in chloride-rich or acidic conditions such as marine or chemical applications. The combination of precise machining and optional surface treatments ensures long-term stability, minimal maintenance, and resistance to oxidation, even under extreme conditions.

High Fatigue Resistance for Repetitive Loads

Components produced via our CNC lathes demonstrate superior fatigue resistance, making them ideal for parts subjected to repeated mechanical stress, such as shafts, fasteners, and structural assemblies. This ensures long-term durability, reduces failure rates, and enhances safety in critical applications including medical implants, aerospace assemblies, and high-performance automotive parts.

Customization Workflow

We provide a structured customization workflow that ensures parts meet client specifications while maintaining high production efficiency.

-

Requirement Analysis: Our engineering team collaborates with clients to capture all project specifications, including dimensions, tolerances, material selection, and surface finish requirements.

-

Feasibility Assessment: Each project undergoes a detailed evaluation to identify the most suitable machining strategy, cutting tools, and production methods to ensure efficiency and accuracy.

-

Prototype Development: For complex or critical components, we provide small-batch prototyping for review and approval, allowing clients to verify dimensions, tolerances, and functional performance before mass production.

-

Precision CNC Machining: Using 4-axis and 5-axis live tooling lathes, we execute precise cutting, turning, and milling operations, producing parts with tight tolerances and consistent surface finishes.

-

Surface Finishing & Treatment: Optional finishing processes such as anodizing, polishing, passivation, or PVD coating can be applied to enhance corrosion resistance, aesthetics, and functional performance.

-

Quality Assurance: Every part undergoes 100% inspection, including dimensional verification, material testing, and surface evaluation, ensuring that only fully compliant products are delivered.

-

Packaging & Delivery: Parts are securely packaged for shipment, with expedited options available to meet project timelines.

This workflow guarantees seamless integration from client inquiry to final delivery, ensuring products meet both technical and aesthetic requirements.

Product Specifications

| Feature | Details |

|---|---|

| CNC Machining | 4-Axis / 5-Axis Live Tooling CNC Lathe |

| Material Capabilities | Titanium, Stainless Steel, Aluminum, Brass, Bronze, Copper, Steel Alloys |

| Micro Machining | Yes |

| Size | Customized per client drawing |

| Color | Customized |

| Tolerance | As per customer request |

| Type of Machining | Turning, Milling, Drilling, Broaching, Etching, Laser, Wire EDM |

| Place of Origin | Guangdong, China |

| OEM/ODM | Accepted |

| Quality Control | 100% Inspection |

Request Your Tailored Quote

Secure Your High-Precision CNC Lathe Parts Today

Shenzhen Huarui Century Technology Co., Ltd. provides factory-direct access to fully functional CNC lathe parts with live tooling, engineered for precision, durability, and high-performance applications. Submit your design specifications, drawings, and material requirements to receive a customized quote including pricing, lead time, and optional finishing processes.

Act now to optimize your manufacturing workflow with precision-engineered CNC lathe parts designed to exact specifications.

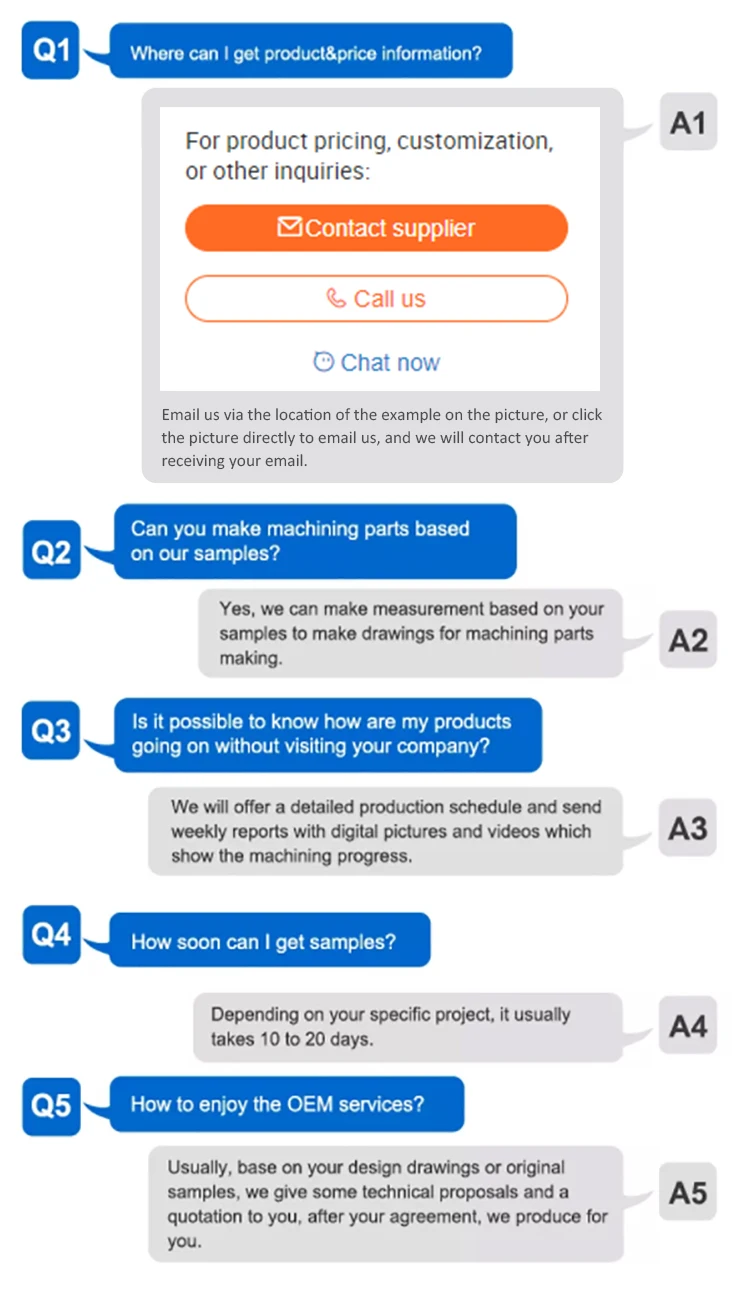

Frequently Asked Questions (FAQ)

Q1: What materials are available for live tooling lathe parts?

A1: We can machine titanium, stainless steel, aluminum, brass, bronze, copper, and other steel alloys. Custom materials are accepted upon request.

Q2: Do you provide both prototypes and mass production?

A2: Yes. We offer small-batch prototyping for evaluation as well as full-scale production.

Q3: What tolerances can be achieved?

A3: Depending on geometry and material, we can achieve tolerances as tight as ±0.01 mm.

Q4: Can you provide surface finishes?

A4: Yes, including anodizing, polishing, mirror finish, passivation, and PVD coatings tailored to your application.

Q5: How is quality controlled?

A5: Each part undergoes 100% inspection including dimensional verification, material testing, and visual assessment to ensure full compliance with client specifications.

Q6: Are OEM and ODM orders supported?

A6: Absolutely. We provide flexible OEM and ODM services for both private-label and customized product development.

Q7: What is the typical lead time?

A7: Prototypes typically ship within 7–15 days, while mass production timelines depend on part complexity and order quantity.