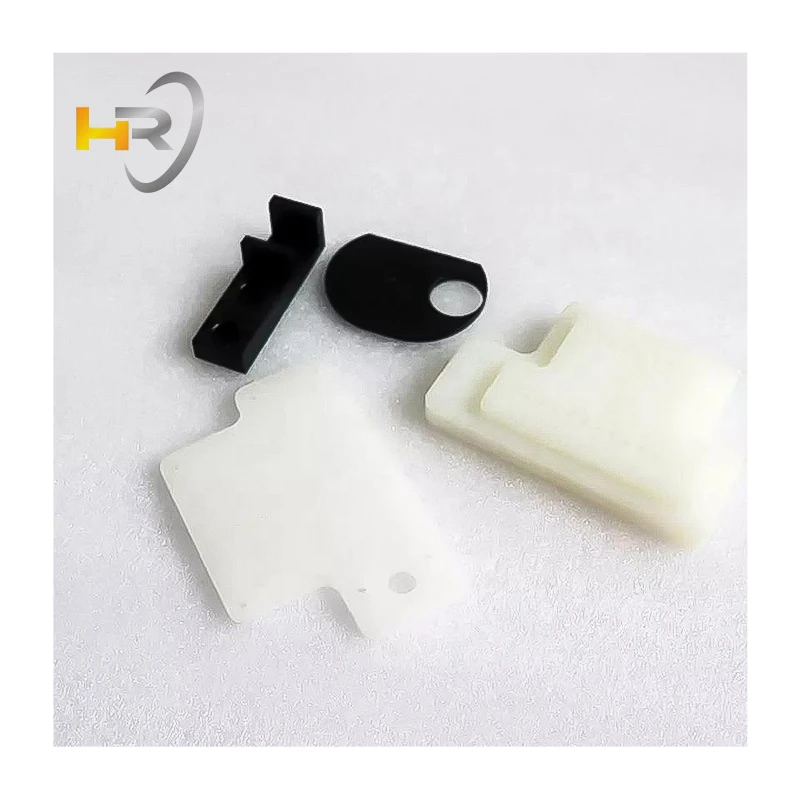

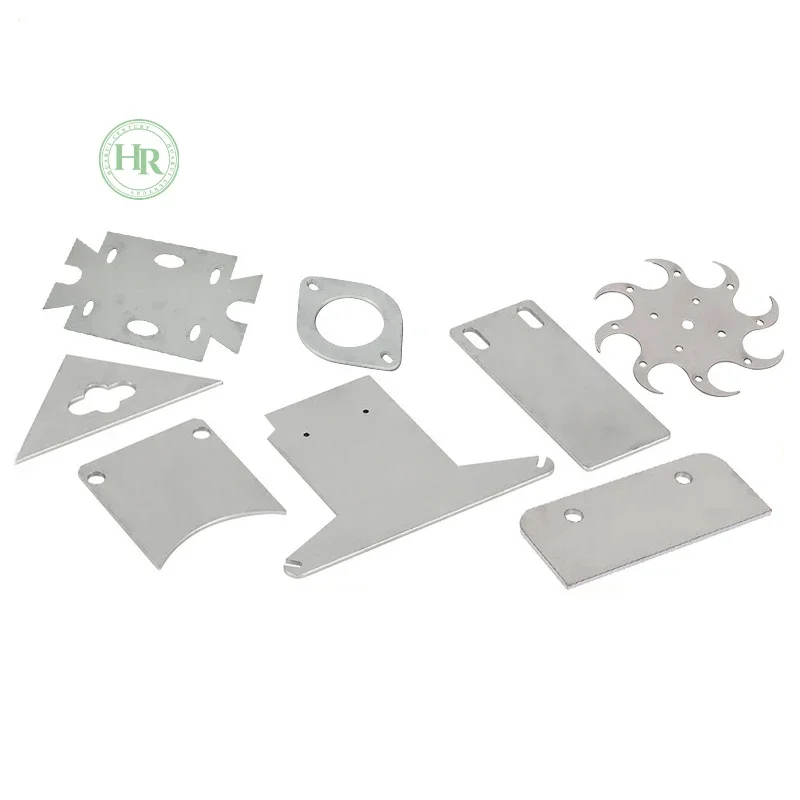

Custom aluminum stainless steel laser cutting bending welding sheet metal fabrication parts service

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Professional engaged in the research, development, sale and service of stamping parts lathe products , die casting products, mould products, and spring parts. We are located in Pinghu, Long Gang District, shenzhen ctiy, Guang dong province, China with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In addition, we have obtained IS O9 0 0 1 certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as North and South America Europe, Middle East. Asia , Africa and so on. and Our products gain wide praises at home and abroad. At the same time, We also welcome OE M and O D M orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements,we sure that we can satisfy your request and provide best quality and service. We warmly welcome customers from at home and abroad to establish cooperation and create a bright future with us together

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. is a professional OEM sheet metal fabrication supplier specializing in custom aluminum and stainless steel laser cutting, CNC bending, precision welding, and complete metal fabrication services. We deliver high-accuracy components suitable for industrial equipment, automation systems, electronics enclosures, machinery parts, transportation structures, medical device housings, and more.

Our sheet metal solutions are designed to meet strict dimensional tolerances and surface quality requirements. With advanced laser cutting automation lines and state-of-the-art bending and welding equipment, we ensure exceptional consistency, fast turnaround, and competitive production costs.

Key performance attributes:

-

Superior Cutting Precision: Capable of maintaining tolerance up to ±0.1 mm, ensuring tight fits and accurate geometries for complex metal components.

-

High Production Efficiency: Laser cutting enables rapid processing speeds, optimized nesting, and reduced material waste for cost-effective production.

-

High Compatibility with Multiple Alloys: Aluminum, stainless steel, carbon steel, galvanized steel, copper, and coated materials are all processed with equal reliability.

-

Minimal Thermal Distortion: Laser technology creates a small heat-affected zone, maintaining the original mechanical properties of the material and ensuring a clean, smooth finish.

-

Scalable Manufacturing: From rapid prototype engineering to high-volume fabrication orders, we support flexible batch sizes without mold investment.

Through a combination of precision cutting, intelligent programming, and full-process fabrication, Huarui Century delivers ready-to-assemble metal parts that meet international quality standards across diversified industries.

Product Advantages

1. High-Precision Cutting with Excellent Edge Quality

Our laser cutting process produces smooth edges, ultra-narrow kerfs, and accurate geometries without the need for additional machining. This ensures that fabricated parts maintain aesthetic appearance and dimensional reliability even for delicate structural designs such as micro-holes, fine slots, and dense perforations. The contact-free cutting method eliminates tooling wear, resulting in consistent accuracy and superior repeatability for mass production.

2. Flexible Manufacturing, Short Lead Time, Lower Tooling Costs

Laser-based sheet metal production enables quick conversion from design to finished parts, making it highly suitable for customized orders and frequent design iterations. The absence of specialized tooling significantly reduces cost burdens on prototype development and low-volume production. We support fast CAD/CAM programming and rapid switching between product types, aligning with modern agile and on-demand manufacturing models.

3. High Material Utilization and Design Freedom

Our cutting layout optimization improves material nesting efficiency, reducing metal scrap and cost consumption. Combined with bending, welding, and optional engraving operations, we can deliver parts with complex 3D shapes, sharp internal corners, and decorative structural features. This flexibility enables customers to achieve structurally optimized, lightweight, and aesthetically refined components without compromise.

Application Scenarios

Shenzhen Huarui Century provides full-process sheet metal fabrication services, covering various sectors that demand structural strength, corrosion resistance, and premium cosmetic appearance. Typical applications include:

-

Electrical and Electronics Industry

Control cabinets, instrument housings, racks, server chassis, power distribution enclosures -

Industrial Machinery & Automation Equipment

Machine frames, conveyor brackets, safety guards, robotics mounting plates -

Automotive & Mobility Components

Stainless steel exhaust systems, protective panels, vehicle interior structural supports -

HVAC and Ventilation System Parts

Ducting elements, louvers, air filter frames for commercial and industrial facilities -

Retail Display and Architectural Hardware

Decorative sheet metal walls, signage structures, metal furniture components -

Energy and Telecommunications

Battery enclosures, inverter mounting plates, telecom equipment casings

Each part is engineered with precision fitment, functional stability, and long-life performance, fulfilling the requirements of modern industrial standards.

Request a Quote

Shenzhen Huarui Century Technology Co., Ltd. offers one-stop custom aluminum stainless steel laser cutting, bending, and welding sheet metal fabrication services with:

-

Advanced production technology for complex geometries and precise tolerance control

-

Full support for small batch prototypes and mass production orders

-

Material sourcing, surface finishing, and assembly-ready delivery

-

Strict QA inspection and traceable process data

Send us your drawings (PDF, DWG, DXF, STEP, or STP) and specifications today to receive a fast quotation tailored to your project. We ensure cost-effective solutions, dependable delivery schedules, and technical support throughout the project lifecycle.

Your components. Our expertise. Perfect results.

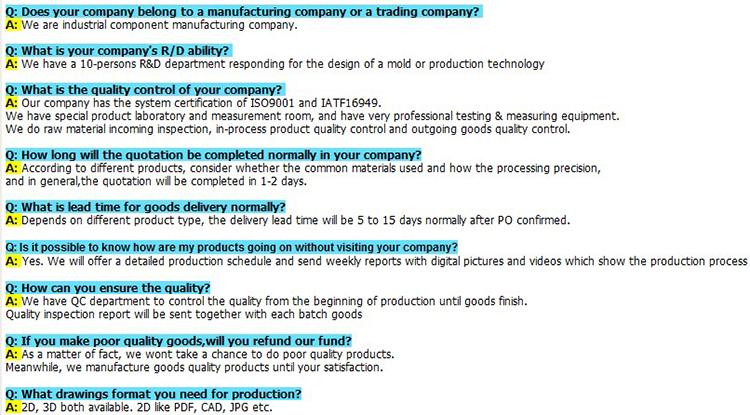

Frequently Asked Questions (FAQ)

Q1: What metals can you fabricate?

A1: We process stainless steel, aluminum alloys, galvanized steel, carbon steel, and copper with thicknesses commonly from 0.5–20 mm.

Q2: What file formats do you accept?

A2: We support STEP, STP, IGES, DWG, DXF, PDF, and other standard CAD formats.

Q3: Do you provide finishing services?

A3: Yes, including powder coating, anodizing, polishing, brushing, sandblasting, screen printing, and more.

Q4: Can you assist with design improvement?

A4: Our engineering team provides DFM support, helping optimize manufacturability and reduce costs.

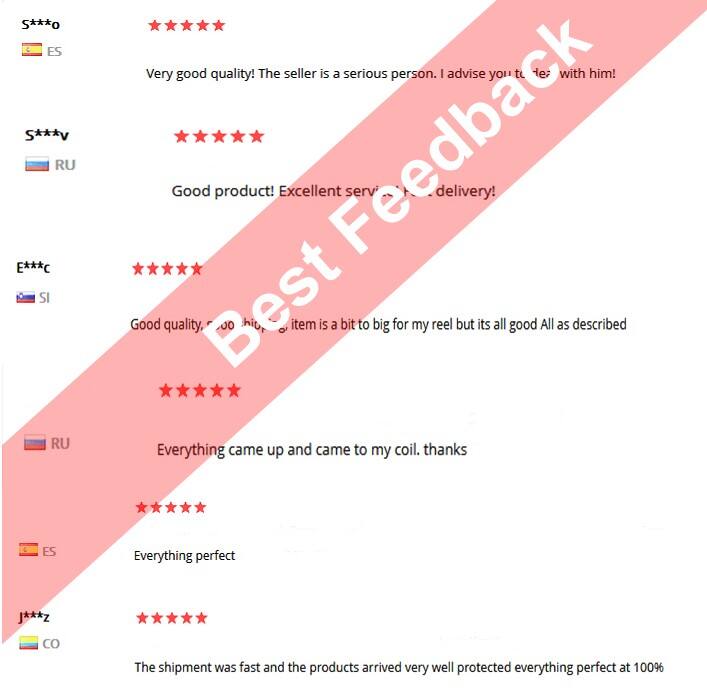

Q5: How do you guarantee quality?

A5: We conduct CMM dimensional inspection, visual surface checks, and weld penetration testing, complying with industry standards.

Q6: What is the typical lead time?

A6: Based on complexity, prototype parts can be delivered within 5–10 working days, and mass production timelines are confirmed upon review.

Q7: Do you support assembly and packaging services?

A7: Yes, we offer customized assembly and secure export packaging to ensure components arrive in perfect condition.