Huarui

Looking for a dependable and OEM/ODM aluminum CNC parts Stainless-steel aluminum brass bent stamping parts? Search no further thanthis brand.

Our business focuses primarily on creating and manufacturing a myriad of top-quality steel components, including metal stainless aluminum, metal, bent stamping components, plus much more. Our items are designed out from the materials standard greatest and usually are manufactured to endure.

If you want custom CNC components for your needs, we now have a skilled group of developers who is able to work with you to produce an ideal solution to your requirements. As a result of our contemporary production technology and gear, we are able to manage big and tiny tasks with simplicity, offering you quick turnaround times and solution great.

We recognize that every task is different, so in retrospect an assortment can be expected by you comprehensive of CNC components. We're able to produce a solution custom fits your preferences and spending plan whether you will require Bit, intricate components or bigger, more technical designs.

In addition to our CNC components, we offer a selection of stainless, aluminum, metal, bent components being stamping suit a true number of companies. From automotive and aerospace to products medical electronic devices, our items are trusted by organizations around the world.

Our items are proudly manufactured in the USA and they are usually designed to meet the greatest criteria of quality and durability. With over 10 years of expertise on the market, we've got built a track record of quality as they are focused on exemplary supplying towards the clients and solution.

In addition to our brand standard additionally provide customized design services for many who desire a remedy unique their tasks. Our experienced selection of developers and designers will work closely to you to develop an item exclusive satisfies your unique needs and requirements.

At Huarui, we're specialized in delivering the item quality things greatest and answers to the clients. We now have confidence in building strong and relationships enduring our clients, so in retrospect you may expect exceptional support and assessment solutions. Contact us to learn more about our products and services or even to request an estimate for the task today.

Material |

Iron, Zn Alloy, Aluminum Alloy, Stainless steel, Aluminum |

Process precision |

Die casting, lathe, spring, cnc, stamping |

OEM |

Available |

MOQ |

1Pcs |

Mass lead time |

15-20 days |

Sample time |

3-7 days |

Payment terms |

T/T, L/C, Money Gram, PayPal, Crash, Western Union |

Country of origin |

Shenzhen, China |

Product Introduction

Product Overview

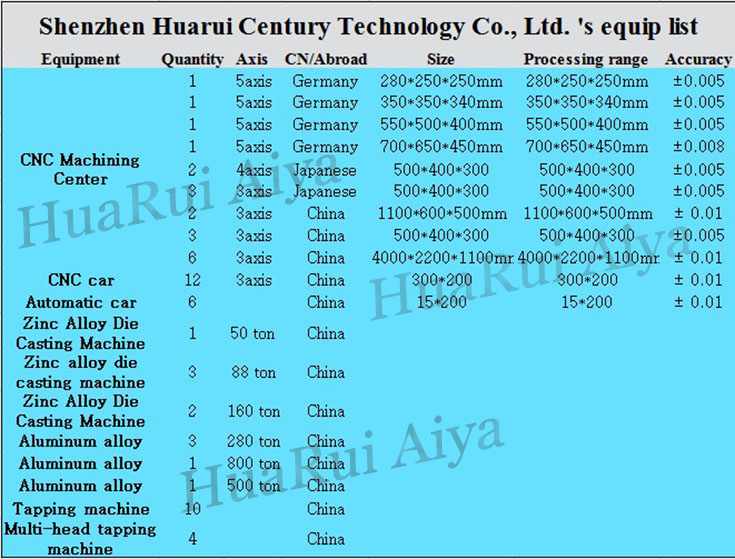

Shenzhen Huarui Century Technology Co., Ltd. specializes in delivering high-precision OEM/ODM aluminum CNC parts, stainless steel machining parts, and brass bent stamping components for global industrial customers. With advanced multi-axis CNC machining centers, stamping presses, and bending equipment, we support complex geometries, tight-tolerance features, and diverse application scenarios. Whether it is lightweight design for electronics or high-strength structural parts in machinery, we offer tailored fabrication with reliable and repeatable production quality.

Product Performance

Our aluminum CNC parts and stamping components are engineered to deliver high dimensional accuracy, stable mechanical properties, and excellent surface finishing compatibility. Performance advantages include:

• Tight tolerances up to ±0.01 mm for precision assemblies

• Consistent shaping and forming quality for thin-wall and complex structures

• High wear resistance, corrosion stability, and deformation control

• Custom finishing options: anodizing, sandblasting, electroplating, brushing, mirror polishing

• Reliable long-term performance under vibration, load, and environmental stress

These components are widely used in automotive, medical, consumer electronics, aerospace, industrial equipment, IoT devices, and communication solutions. Shenzhen Huarui ensures professional project management from prototype design to large-volume delivery.

Product Advantages

Lightweight and High Strength

Aluminum offers an exceptional strength-to-weight ratio, enabling significant structural optimization in automotive frames, UAV parts, and handheld products. Its stability under cyclic loads enhances long-term fatigue resistance. Through advanced cutting strategies, we minimize machining stress and ensure dimensional stability during assembly.

Excellent Thermal and Electrical Conductivity

Aluminum dissipates heat efficiently, making it ideal for heat sinks, LED housings, and power system modules. Superior electrical conductivity supports grounding, shielding, and contact applications in communication devices. We can integrate fins, channels, and precision mating surfaces to enhance performance in thermal and electrical systems.

High Compatibility With CNC and Surface Processing

Aluminum supports multi-axis milling, precision turning, and stamping technologies. It enables accurate manufacturing of intricate contours, deep cavities, and thin features. Using our optimized toolpaths, efficient chips removal, and strict machine tuning, we maintain consistent cutting results. Anodizing, coating, and polishing further enhance corrosion protection, visual appeal, and friction control.

These features make OEM/ODM aluminum CNC parts cost-efficient, functional, and adaptable across modern engineering demands.

Production Process

Step-by-Step Manufacturing Flow

To ensure outstanding quality for aluminum CNC parts, stainless steel components, and brass bent stamping parts, we implement a rigorous and fully traceable production system:

-

Engineering Consultation & DFM Analysis

Evaluation of drawings, tolerance requirements, mechanical functions, and cost optimization. -

Raw Material Selection & Incoming Inspection

Certified aluminum alloys, stainless steels, and brass materials undergo strict verification and traceability review. -

Precision CNC Machining & Metal Stamping Shaping

Utilizing 3/4/5-axis machining centers, CNC lathes, bending presses, and progressive stamping dies to achieve accuracy and efficiency. -

Surface Treatment & Functional Enhancement

Options include anodizing, anodic sealing, sandblasting, brushing, electroplating, powder coating, and laser marking. -

Final Inspection & Quality Reporting

Quality is verified using 3D CMM, height gauges, microscopes, and mechanical property tests before shipment. -

Packaging & On-Time Shipping

Customized industrial packaging protects parts from abrasion and corrosion. Flexible delivery supports global logistics and JIT supply.

This refined workflow ensures product performance and consistency across prototypes and mass-production orders.

Get a Fast Quote and Professional Support

How to Start Your Custom Project

We welcome new OEM/ODM cooperation and purchasing requests. Please send your 2D/3D files or samples, and we will provide:

• Fast quotation within 24 hours

• Professional engineering support and feasibility suggestions

• Rapid prototypes for design verification

• Cost-competitive mass-production capability

Our sales and technical service teams ensure high-efficiency communication and long-term supply stability.

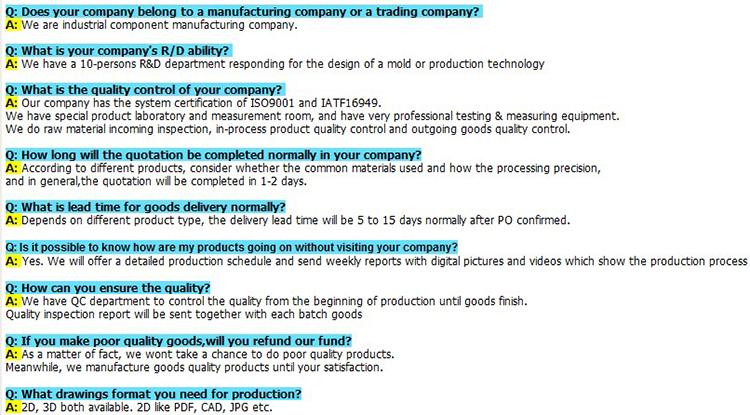

FAQ

Common Questions from Buyers

Q1: Which file formats do you accept?

STEP, STP, IGES, DWG, DXF, PDF, SolidWorks files, etc.

Q2: What is your MOQ for CNC machining or stamping?

No strict MOQ. We support prototypes to mass production.

Q3: Available surface finishing methods?

Anodizing, electroplating, sandblasting, brushing, polishing, powder coating, and laser etching.

Q4: Which industries do you mainly serve?

Automotive, aerospace, medical, electronics, robotics, telecommunications, and consumer products.

Q5: How do you ensure product quality?

Strict inspection standards, process monitoring, and traceable records throughout production.