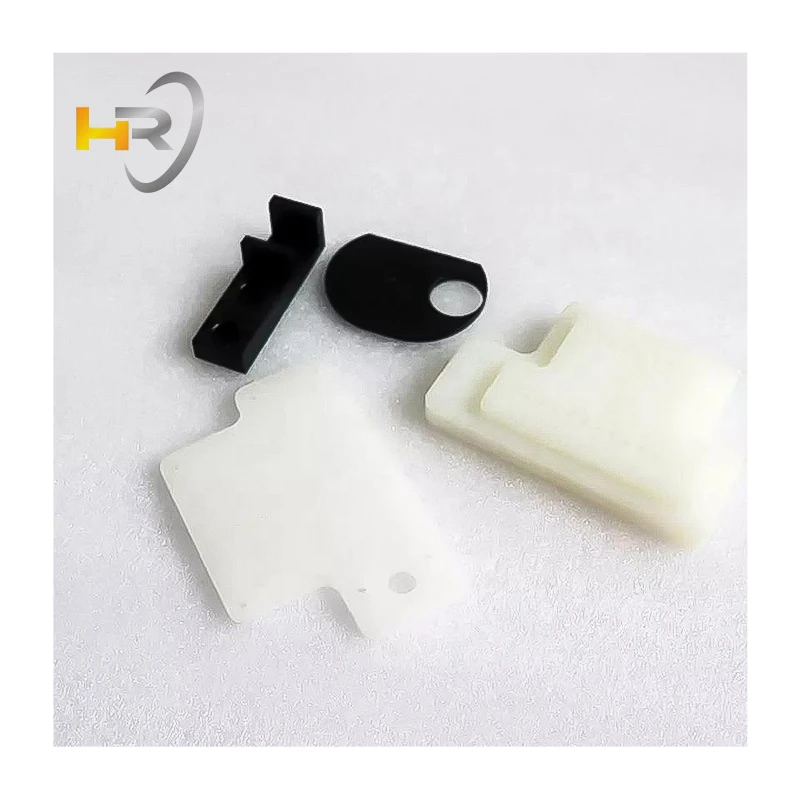

Deep drawn sheet metal manufacturer custom stamping metalnwork stainless steel cut aluminum deep drawing service

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

| Name | custom manufacturing sheet metal fabrication聽 parts service |

| Materials | Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

| Surface Treatment | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

| Tolerance | +/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Testing equipment | CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

| Processing | Stamping ,Sheet metal fabrication |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Our Advantages | 1.) 24 hours online service & Quickly Quote/Delivery. |

| 2.) 100% QC quality inspection before delivery, and can provide quality inspection form. | |

| 3.) To provide production design, production and technical service, mould development and processing, etc |

Product Overview

Product Introduction

As a professional deep drawn sheet metal manufacturer, we specialize in custom stamping metalwork, stainless steel cutting, and aluminum deep drawing services tailored to meet diverse industrial requirements. Our manufacturing solutions support high-performance enclosure products, structural hardware, and functional metal components across sectors such as automotive, electronics, telecommunications, household appliances, industrial machinery, and medical devices.

Each deep drawn product is formed through controlled material flow to achieve seamless geometry, stronger structural characteristics, and improved internal grain continuity. From ultra-thin sheets to medium-thick materials, our processing capabilities ensure exceptional stability and deformation resistance, suitable for high-strength housings, sealed components, and precision mounting structures.

Product Performance Attributes

-

High tensile strength and durability ensured through stainless steel or aerospace-grade aluminum alloys.

-

Smooth surface finish dictated by mold precision, suitable for post-processing methods such as powder coating, anodizing, passivation, or plating.

-

Tight forming tolerances realized by automated stamping systems, ensuring repeat accuracy throughout mass production.

-

Custom geometries such as ribs, flanges, or deep cavities formed without welding, resulting in improved mechanical performance.

-

Corrosion-resistant properties engineered for both indoor and outdoor industrial environments.

Our end-to-end services include engineering consulting, mold development, prototyping, mass production, and quality inspection to ensure the highest performance and product integrity.

Product Advantages

High Material Utilization Through Optimized Nesting

Deep drawing minimizes cutting waste compared with multi-step fabrication processes. By optimizing sheet distribution, we significantly improve the utilization rate of raw materials such as stainless steel and aluminum sheets, allowing cost reduction while supporting sustainable manufacturing. This offers a major advantage for customers with long-term, large-volume supply plans.

Capable of Ultra-Precise, Miniature Component Manufacturing

We support micro-forming applications including miniature shielding clips, micro housings, EMI contacts, and precision functional parts used in electronics and sensor systems. With high-accuracy presses and stable tooling design, tolerance control meets strict assembly requirements, even for extremely compact components where space allowance is limited and precision is essential.

Automation-Ready Production for Scalability

Our stamping lines integrate feeding automation, robotic transfer, inline lubrication control, and continuous monitoring systems. This ensures:

-

Consistent production speed and superior process reliability

-

Adaptability to progressive die stamping for unmanned continuous production

-

Rapid scaling while maintaining process stability and cost efficiency

These capabilities reinforce our position as a preferred deep drawing supplier for mass-market consumer products, structural automotive parts, and industrial-grade enclosures that demand long production lifecycles.

Customization Process

Professional and Transparent Service Workflow

To ensure seamless project delivery and manufacturing efficiency, we provide a structured customization process:

-

Demand Communication and Feasibility Analysis

Customers provide drawings, materials, and functional specifications. Our engineering team reviews manufacturability and offers design improvement suggestions. -

Quotation and Project Confirmation

Pricing is based on tooling complexity, production volume, tolerance requirements, and finishing standards. Lead time estimates are provided upfront for firm scheduling. -

Mold Design and Manufacturing

Tooling is modeled with deformation simulation to address springback control, stress concentration, and wrinkle prevention. -

Trial Production and Dimensional Verification

First-run samples are validated using CMM and visual inspection to confirm structural stability and tolerance compliance. -

Mass Production with Continuous Monitoring

Automated stamping lines maintain consistent quality, while real-time process control ensures efficient cycle time. -

Surface Finishing and Post-Processing

Value-added services include laser cutting, spot welding, CNC machining, deburring, and protective treatments. -

Inspection, Packaging, and Shipment

Final batch inspection reports are provided. Packaging follows international export standards to safeguard products during transportation.

This workflow ensures complete traceability and quality management from concept to final delivery.

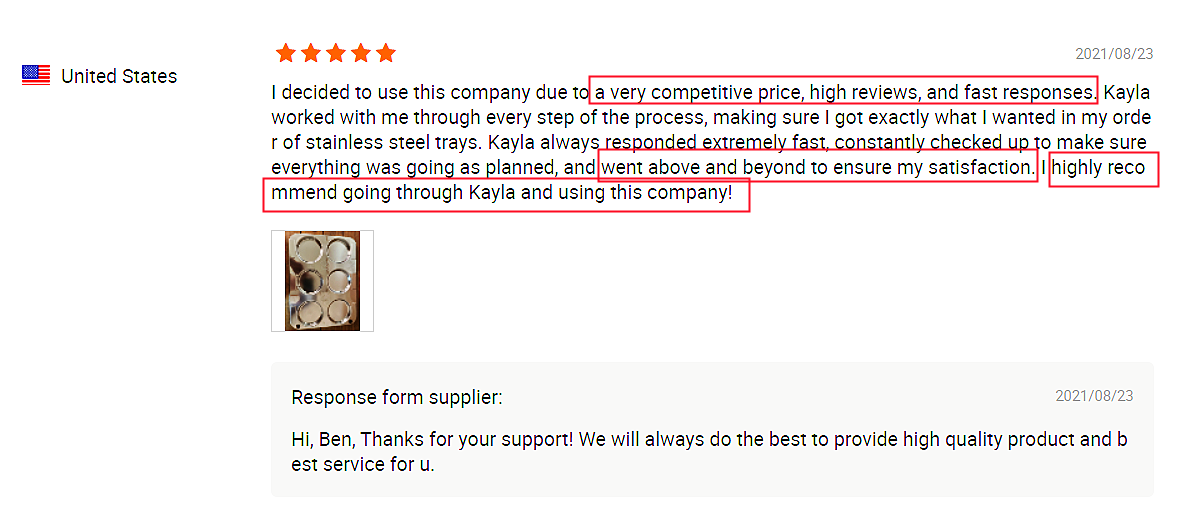

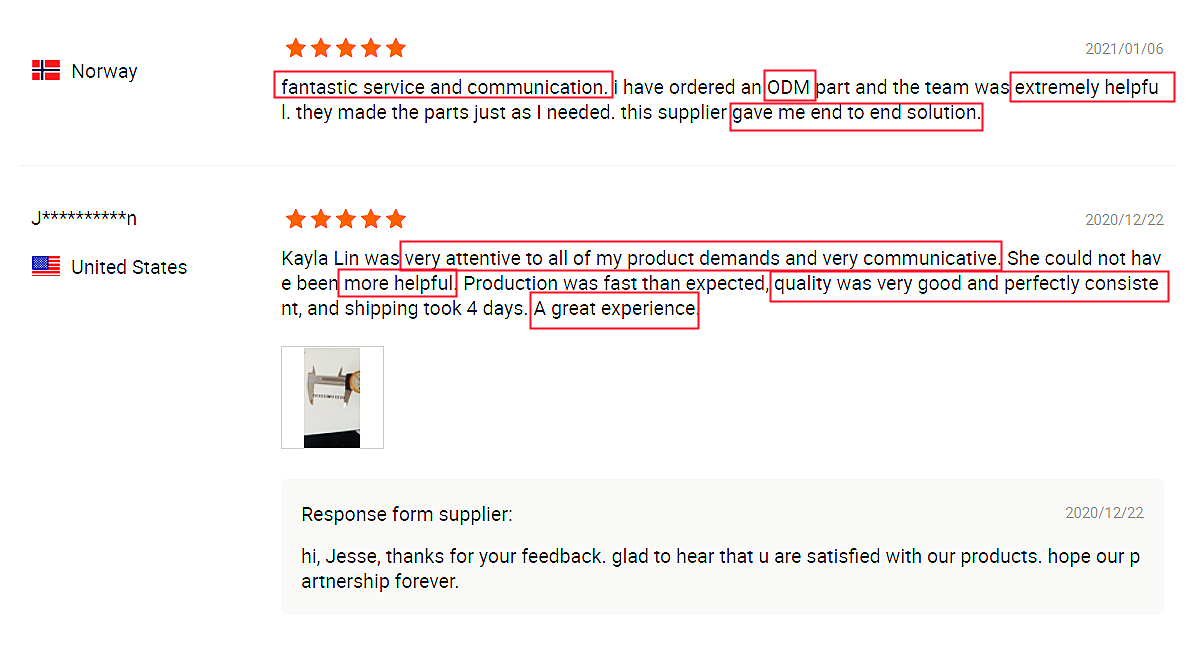

Inquiry Engagement Section

We welcome OEM/ODM customization requests regardless of complexity. To help us deliver exact technical solutions, please share:

-

Engineering drawings (STEP/IGES/PDF)

-

Required material grade and thickness

-

Surface finishing and functional details

-

Estimated annual usage or order quantity

-

Certification standards (RoHS, REACH, IP rating, etc.)

Our technical experts respond promptly with professional suggestions and competitive pricing. Connect with us now to accelerate manufacturing efficiency and secure stable supply support for your industrial products.

Frequently Asked Questions (FAQ)

Q1: What materials can you deep draw and stamp?

We work with stainless steel, carbon steel, aluminum, copper, galvanized sheet, and other ductile metals.

Q2: Can you provide prototyping before investing in full tooling?

Yes. Prototype development is available to confirm design feasibility and assembly requirements.

Q3: How do you ensure the quality of deep drawn components?

We apply SPC, dimensional validation, destructive testing when necessary, and full inspection reports upon request.

Q4: What industries do you mainly serve?

Automotive, electronics, aerospace accessories, industrial power systems, home appliances, medical equipment, and security devices.

Q5: What is the typical mold lead time?

Depending on complexity, mold development generally takes 3 to 6 weeks.

Q6: How do you handle design modifications after stamping begins?

We advise completing all design validation during the sampling stage. Post-tooling design changes may require mold re-engineering, leading to additional cost.

Q7: Do you support global shipping?

Yes. We offer efficient export logistics to support customers worldwide.