Precision Aluminum Hardware Parts CNC Drilling Milling Components Custom OEM

Engineer your devices with reliability from the ground up. We specialize in manufacturing high-precision aluminum hardware parts and components through expert CNC drilling and milling processes. Our parts, including brackets, enclosures, panels, and fixtures, are machined to exacting tolerances of ±0.01mm, ensuring seamless assembly and long-term performance in automation, instrumentation, and machinery. Backed by rigorous quality control, consistent batch-to-batch repeatability, and in-house surface finishing like anodizing, we provide a dependable source for custom OEM components that form the critical backbone of your products.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

You are very welcome to visit us among many suppliers

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Behind every smooth-operating machine, every reliable piece of test equipment, and every robust electronic assembly lies a network of critical, often overlooked components: the hardware. Brackets, mounting plates, housings, and connectors—these parts form the essential skeleton that holds everything together. At our core, we are specialists in this fundamental domain. Our CNC machining service is dedicated to producing high precision aluminum hardware parts that are far from commodities; they are engineered components where accuracy, consistency, and durability are non-negotiable. By focusing on the unique demands of hardware tools and assembly components, we deliver the reliability that your end products demand, making us a trusted partner for OEM manufacturers worldwide.

Why Aluminum Reigns Supreme for Modern Hardware Components

The choice of aluminum for hardware is a strategic engineering decision. Its exceptional strength-to-weight ratio allows for the creation of sturdy, load-bearing parts like brackets and frames without adding unnecessary mass—a key advantage in portable equipment and automated systems. Aluminum's natural corrosion resistance ensures longevity in diverse environments, while its excellent machinability allows for the complex CNC drilling and milling required for intricate features, tight-tolerance holes, and smooth finishes. Furthermore, it serves as an effective thermal conductor for heat dissipation and provides a superb substrate for functional surface treatments like anodizing. When you choose our aluminum hardware parts, you select a material whose properties are perfectly aligned with the demands of high-performance, durable hardware.

Mastering the Craft: The Critical Symbiosis of Drilling and Milling

Creating flawless hardware components requires a deep understanding of integrated processes. CNC drilling is not merely making holes; it is about achieving precise hole location, perfect diameter control, and ideal surface finish for subsequent operations like tapping or press-fitting bearings. Our expertise ensures burr-free, straight, and round holes that are critical for smooth assembly. Complementary to this, CNC milling defines the part's external geometry, creates flat mounting surfaces with exacting flatness, and machines complex pockets and slots. The true value emerges when these processes are executed in a coordinated sequence, often within a single setup on our advanced machining centers. This “done-in-one” approach guarantees perfect alignment between drilled holes and milled surfaces, eliminating cumulative error and ensuring your hardware parts fit together precisely as designed, every time.

Precision as a Promise: The Cornerstone of Flawless Assembly

In hardware, precision is the currency of efficiency. A bracket with misaligned mounting holes or a panel with uneven surfaces can bring an assembly line to a halt. Our commitment to high precision CNC machining is absolute, with standard tolerances held within ±0.01mm. This capability is vital for components like spacer plates that define critical gaps, or fixture plates that locate other parts during assembly. We achieve this not only through advanced equipment but through meticulous process design, including the use of specialized tooling for aluminum and controlled machining parameters that prevent deflection and heat-induced distortion. The result is aluminum components that enable rapid, effortless assembly, reduce labor costs for fitting and adjustment, and contribute directly to a higher-quality final product with improved performance and reliability.

Beyond the Blueprint: Ensuring Consistency Across Every Batch

For OEMs and equipment manufacturers, part consistency is as important as initial accuracy. Variations between batches can disrupt production schedules and compromise product quality. Our manufacturing philosophy is built on delivering repeatable results. We employ statistical process control (SPC) principles to monitor key dimensions during production runs, ensuring stability. Every batch of CNC machining parts undergoes our stringent 100% quality inspection protocol, utilizing tools like Coordinate Measuring Machines (CMM) to verify critical features against your master drawing. Detailed inspection reports are available with every shipment, providing full traceability and peace of mind. This unwavering focus on consistency makes us more than a shop; we become a reliable extension of your production floor, delivering parts you can install with confidence, from the first prototype to the thousandth production unit.

Application in Action: Hardware Engineered for Specific Challenges

Our components serve as the building blocks across a vast landscape of industries. In industrial automation, we machine precise linear guide brackets, robust sensor mounts, and intricate actuator housings that withstand constant motion and vibration. The test, measurement, and instrumentation sector relies on our flat, stable optical breadboards, precision-machined enclosure panels for sensitive electronics, and custom fixture plates for calibration equipment. For communications and data hardware, we produce RF enclosures with EMI shielding considerations, heat sink mounts, and server rack components. Even in general machinery and product design, our custom brackets, handles, and structural frames provide lightweight yet durable solutions. This diverse experience equips us to understand the functional context of your hardware needs from the first consultation.

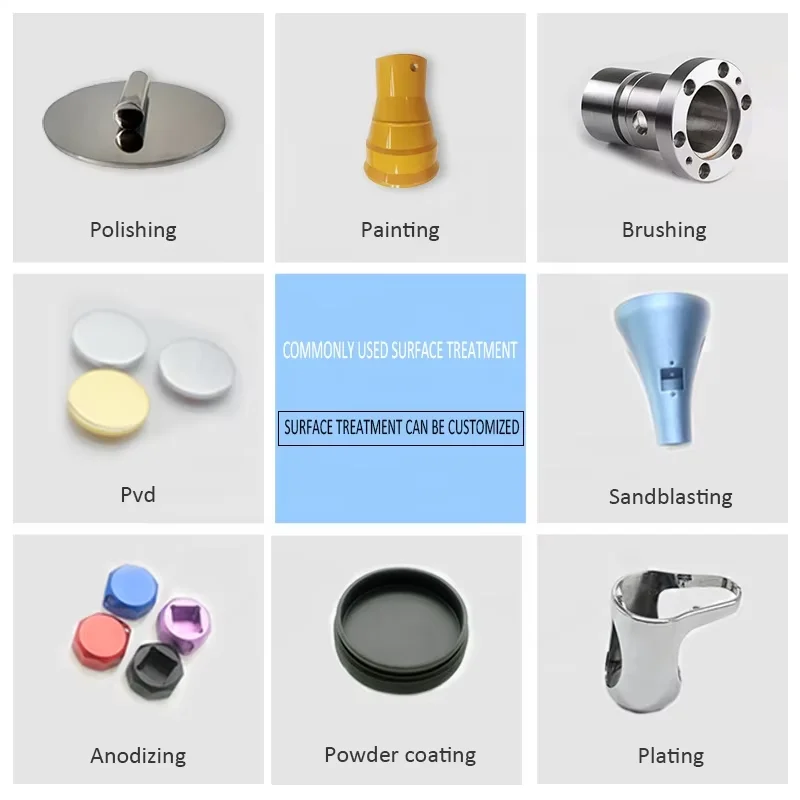

The Finish That Fortifies: Surface Treatments for Enhanced Performance

The journey of a hardware part is not complete at machining. The right surface treatment enhances its properties and prepares it for its working life. We offer a complete range of surface treatments tailored for aluminum hardware. Anodizing is the most common, providing a hard, wear-resistant, and corrosion-resistant layer that can be dyed in various colors for branding or identification. For parts requiring electrical conductivity or a specific aesthetic, we offer chemical film conversion coatings. We also provide bead blasting for a uniform matte finish and brushing for a distinctive linear grain. By managing these processes in-house, we ensure a seamless workflow, consistent quality, and a single point of responsibility for the entire component, from raw material to a finished, protected part ready for your assembly line.

Partnering for Success: A Streamlined Path from Design to Delivery

Initiating a partnership for your critical hardware components should be straightforward. Our process is designed for clarity and collaboration. Share your part drawings or 3D CAD files with our engineering team. We will conduct a complimentary Design for Manufacturability (DFM) review, offering practical suggestions to optimize your design for cost-effective CNC drilling and milling without compromising integrity. You will then receive a transparent, competitive quotation. Upon project approval, a dedicated project manager oversees all aspects of production and logistics, keeping you informed. Supported by our 24-hour online service and global shipping options, we ensure a reliable and responsive supply chain. As your manufacturing partner, we are committed to delivering the high-quality, dependable aluminum hardware parts that form the reliable foundation of your innovative products.