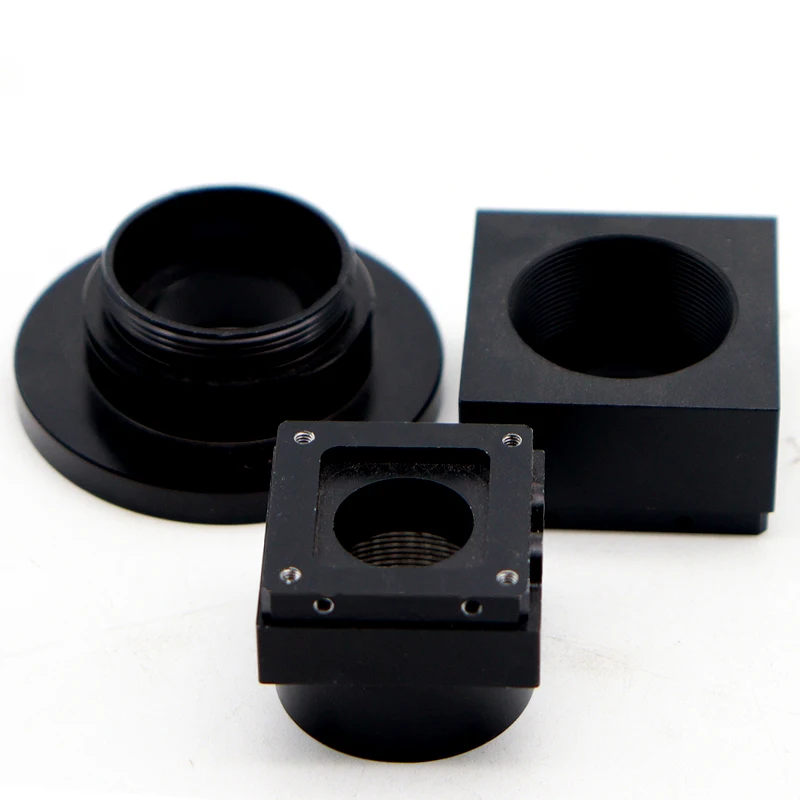

Precision Aluminum CNC Machining Parts Lightweight Fabrication High-Speed Milling

Unlock the full potential of aluminum for your next project with our dedicated CNC machining service. We specialize in high-speed precision milling and fabrication of complex, lightweight aluminum parts, from intricate heat sinks and robust structural frames to high-visibility consumer electronics enclosures. Our process leverages aluminum’s excellent machinability to deliver superior surface finishes and hold tight tolerances within ±0.01mm, all supported by comprehensive in-house anodizing and surface treatment. Ideal for applications demanding weight reduction, thermal management, and aesthetic quality in industries like aerospace, automotive, and electronics. Partner with us for a seamless blend of material science and advanced manufacturing.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

You are very welcome to visit us among many suppliers

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

In an era defined by efficiency and performance, aluminum stands as a cornerstone of modern engineering. Its unique combination of light weight, high strength-to-weight ratio, excellent thermal conductivity, and natural corrosion resistance makes it indispensable across countless advanced applications. However, truly capitalizing on these properties requires more than basic machining; it demands a manufacturing partner who understands how to transform this versatile metal into optimized, high-performance components. Our precision aluminum CNC machining service is engineered for this exact purpose. We combine advanced high-speed milling technology with deep material expertise to produce aluminum fabrication parts that are not just made, but engineered—for weight savings, for heat dissipation, for structural integrity, and for market-leading aesthetics.

Material Mastery: Selecting the Right Aluminum Alloy for Peak Performance

Not all aluminum is created equal. The choice of alloy—from the common 6061-T6 to the high-strength 7075 or the machining-friendly 5083—directly impacts the final part’s performance. Our role begins with expert consultation to guide this critical selection. Do you need the weldability and general-purpose strength of 6061 for a structural bracket? The extreme strength of 7075, akin to many steels, for an aerospace fitting? Or the superb finishing characteristics of 5052 for an anodized consumer product faceplate? We understand the nuances of temper designations and how they influence machinability and final part behavior. This foundational knowledge ensures your CNC machining project starts on the right foot, aligning material properties with your functional and budgetary goals for the most effective outcome.

High-Speed Precision Milling: Where Efficiency Meets Exceptional Finish

The phrase “easy to machine” belies the skill required to machine aluminum exceptionally well. Our specialty lies in high-speed CNC milling strategies tailored specifically for aluminum. By utilizing high spindle speeds, specialized tool geometries, and optimized feed rates, we achieve remarkably fast material removal while simultaneously producing surface finishes so smooth they often require minimal secondary polishing. This efficiency translates directly into shorter lead times and cost-effective production, especially for complex aluminum parts. Furthermore, we excel at managing the challenges of machining delicate features. Our programmers employ sophisticated toolpath strategies and custom fixturing to successfully machine thin walls, deep pockets, and fine details without distortion or tool deflection, ensuring your design’s integrity is preserved in the final component.

From Raw Block to Refined Product: Our Integrated Fabrication Workflow

True aluminum fabrication extends beyond milling a single face. Complex parts often require a symphony of processes. Our one-stop processing capability allows us to orchestrate this seamlessly. A single component might progress from multi-axis CNC milling for its primary shape to precision CNC turning for concentric diameters, then to drilling and tapping for fastener holes, and finally to EDM wire cutting for intricate internal features—all under one roof and often in a single setup. This integrated approach eliminates the errors and delays inherent in multi-vendor production, ensures perfect alignment between features, and gives you a single point of accountability for the entire manufacturing process, from the initial billet to the final machined form.

Finishing Touches: Enhancing Function and Form with Advanced Surface Treatments

The journey of an aluminum part is not complete after machining. Surface treatment is critical for enhancing its properties and application readiness. We provide a comprehensive suite of surface treatments in-house. Anodizing is our most requested finish, available in a spectrum of colors; it dramatically improves corrosion and wear resistance while providing electrical insulation. For parts requiring maximum durability, we offer hard coat anodizing. We also perform chemical film conversion coatings for corrosion protection without changing dimensions, and mechanical finishes like precision polishing, bead blasting, and brushing to achieve specific aesthetic textures, from a mirror shine to a uniform matte appearance. This vertical control over finishing guarantees consistent, high-quality results that meet both engineering and visual specifications.

Industry Applications: Powering Innovation Where Performance is Critical

Our aluminum CNC machining expertise fuels progress in sectors where performance margins are thin. In aerospace and automotive, we machine lightweight structural components, drone frames, and engine parts where every gram saved translates to increased range or efficiency. The electronics and telecommunications industries rely on us for precisely machined heat sinks that manage processor temperatures, and for robust, EMI-shielding enclosures for sensitive equipment. In consumer products and industrial design, we produce the high-quality housings, faceplates, and mechanical assemblies where aesthetic appeal and precision are equally important. This broad experience means we don’t just understand machining; we understand the end-use environment your part must thrive in, allowing us to proactively recommend solutions for longevity and reliability.

The Foundation of Trust: Precision Measured and Quality Assured

Even with a “forgiving” material like aluminum, we enforce an uncompromising quality standard. Our commitment to high-quality output is rooted in our ISO-certified quality management system. For every batch of precision aluminum parts, our promise is validated by data. We use Coordinate Measuring Machines (CMM) to perform full 3D inspections, verifying complex geometries against your CAD model to ensure adherence to our ±0.01mm tolerance capability. Surface roughness is measured with precision instruments to confirm finish specifications. We believe in transparent partnership: detailed inspection reports accompany each delivery, and we offer virtual factory tours so you can witness our processes and controls firsthand. This rigorous, evidence-based approach builds the trust necessary for you to integrate our components into your products with absolute confidence.

Your Partner from Concept to Completion: A Streamlined Collaboration

Initiating a project with a specialist in aluminum fabrication is designed to be straightforward and collaborative. The process begins when you share your design files and requirements. Our engineering team promptly conducts a complimentary Design for Manufacturability (DFM) review, providing expert feedback to optimize your part for performance, cost, and manufacturability. You will then receive a clear, comprehensive, and competitive quotation. Upon project approval, a dedicated project manager becomes your single point of contact, overseeing production and providing regular updates. Supported by our 24-hour online service and global logistics network, we ensure a smooth path from prototype to production run. As your manufacturer, we aim to be a true extension of your team, delivering the lightweight, high-performance aluminum CNC machining parts that help bring your most innovative ideas to life.