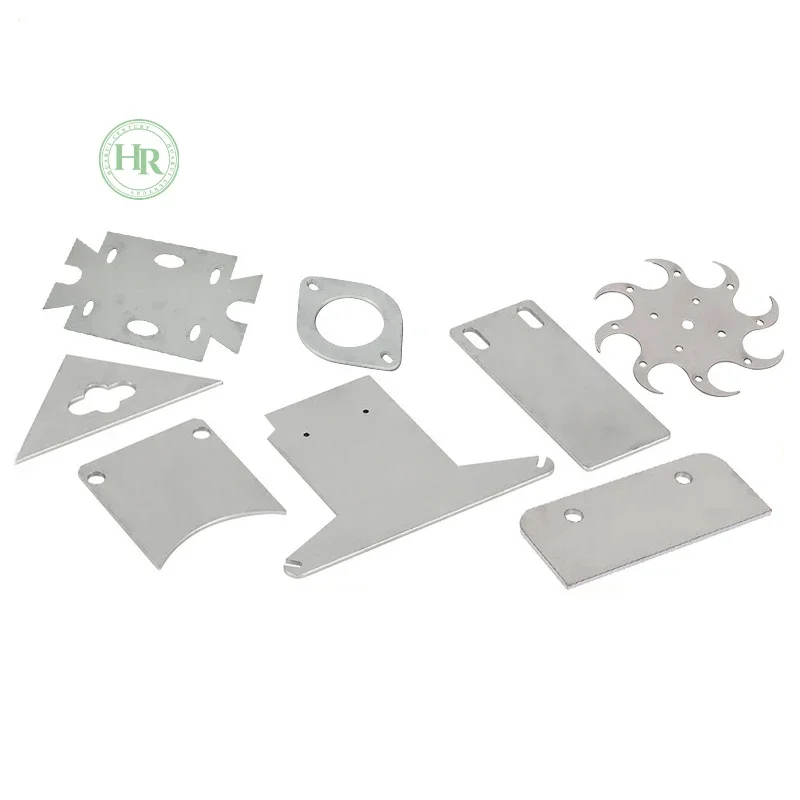

Custom OEM Alloy Steel & Grey Iron Sand Casting Service for Industrial Parts

Unlock the strength and versatility of custom alloy steel and grey iron components through our professional sand casting service. We specialize in producing durable, high-integrity castings tailored for demanding applications in industrial machinery, construction, furniture fittings, and heavy-duty equipment. From prototype to production, we support full customization with comprehensive in-house capabilities including pattern making, casting, CNC machining, and surface finishing. Partner with us for a reliable, transparent manufacturing process focused on quality, precision, and meeting your specific project timelines and requirements.

Process introduction

Craft name |

Die casting parts service |

Mold Material |

Aluminum,SKD61,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Material |

Aluminum:ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized . Zinc: ZA3#, ZA5#, ZA8# or customized . Magnesium: AZ91D, AM60B or customized . |

Surface Treatment |

Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Deep Processing |

CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

Application |

furniture,Industry fittings and Construction and Decoration,etc. |

You are very welcome to visit us among many suppliers

We have very strict quality control process

Q1:What is the specific production process? |

Die designing→Die making→Smelting&alloying→QC→Die casting→remove burrs→QC→Surface treatment→QC→Packing→QC→Shipping→After Sale Service. |

Q2: How soon can I get samples? |

Depending on your specific project, it usually takes 10 to 20 days. |

Q4:Can you make machining parts based on our samples? |

Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

Forging the Backbone of Industry: Your Premier Sand Casting Solution

In the world of heavy industry and robust machinery, the integrity of each component is non-negotiable. Where standard parts fall short, custom-engineered solutions become critical. This is the domain of precision sand casting, a foundational manufacturing process that brings complex, large-scale, and exceptionally strong metal parts to life. For manufacturers, engineers, and buyers sourcing reliable casting partners, finding a foundry that combines traditional craftsmanship with modern quality assurance is key. Our dedicated sand casting service is designed to be that partner, offering unparalleled expertise in transforming alloy steel and grey iron into the durable backbone of your products. We are not just a supplier; we are an extension of your manufacturing team, committed to delivering castings that meet the highest standards of performance and reliability.

Understanding the Sand Casting Advantage: Flexibility Meets Strength

What sets the sand casting process apart in the landscape of metal fabrication? It is fundamentally about versatility and capability. Unlike other methods constrained by mold costs or size limitations, sand casting utilizes a consumable sand mold to create the desired part shape. This approach offers extraordinary flexibility, making it the ideal choice for producing large parts, complex geometries, low to medium volume runs, and prototype development. The economic advantage is clear: lower initial tooling costs allow for greater design freedom and cost-effective production, especially for heavier components. Whether you need a single prototype of a massive gear housing or a batch of intricate brackets for construction equipment, this process provides a reliable and adaptable pathway from concept to solid metal. Our mastery of this foundational technique ensures that your vision for a strong, custom metal part is realized with precision and efficiency.

The Science of Strength: Alloy Steel and Grey Iron Castings

The true potential of any casting is unlocked by the material from which it is made. Our sand casting service specializes in two powerhouse materials renowned for their durability: alloy steel and grey iron.

Alloy Steel Castings:

When your application demands superior strength, toughness, and wear resistance, alloy steel is the definitive choice. By introducing elements like chromium, nickel, and molybdenum, we enhance the base properties of steel to create castings capable of withstanding extreme stress, impact, and abrasive environments. These components are essential in the most demanding sectors, forming the critical parts of mining machinery, heavy vehicle suspensions, and high-stress industrial gears. Our process ensures the metallurgical integrity of each alloy steel casting, providing you with a component built for longevity under pressure.

Grey Iron Castings:

Celebrated for its excellent castability, machinability, and inherent damping properties, grey iron is a cornerstone material for countless industrial applications. The graphite flakes within its microstructure give grey iron exceptional vibration absorption, making it perfect for bases, frames, and housings where stability is crucial, such as in machine tools or compressor blocks. Furthermore, its good wear resistance and thermal conductivity make it a reliable, cost-effective solution for engine components, pump casings, and heavy-duty fittings. Our sand casting process expertly harnesses these properties, producing grey iron castings that offer an unbeatable combination of performance and value for a wide array of uses.

Beyond the Mold: Our Integrated Manufacturing and Quality Pledge

Our commitment to excellence extends far beyond the pouring of molten metal. We operate an integrated manufacturing ecosystem to deliver a finished product that meets your exact specifications. Upon the solidification of your sand casting, our comprehensive in-house deep processing capabilities take over. Our workshops are equipped for CNC machining, precision milling, drilling, and tapping, allowing us to add critical threads, bores, and finished surfaces directly to your casting. This seamless integration from foundry to machine shop guarantees dimensional accuracy, reduces lead times by eliminating third-party handling, and ensures tight coordination throughout production.

Quality is the thread that runs through every stage. Our multi-point inspection protocol mirrors the rigor expected by global partners. It begins with raw material certification and continues through process controls during molding and pouring. After casting, we employ methods such as dimensional checks with calibrated instruments, visual and penetrant testing for surface integrity, and material sampling to verify grade conformity. As a professional manufacturer based in China, we understand the importance of transparency. We keep you informed with regular progress updates, including photos and videos of your parts at key production milestones, so you have visibility and confidence throughout the manufacturing journey without needing to visit the facility.

Engineered for Application: Where Our Castings Perform

The components produced through our sand casting service are engineered to perform in environments where failure is not an option. In the industrial fittings and machinery sector, they form the robust frames, hefty gears, and durable housings that keep production lines running. Within construction and decoration, our castings provide the structural strength for architectural hardware, custom ornamental pieces, and heavy-duty support elements that combine aesthetics with enduring function. For the furniture industry, especially for high-stress commercial or outdoor applications, we supply solid, reliable cast parts for joints, bases, and mechanisms that endure daily use.

This wide applicability stems from our ability to tailor both the material and the process to the challenge at hand. Whether it’s a complex, thin-walled grey iron casting for an engine component or a massive, weight-bearing alloy steel casting for a mining crusher, our expertise ensures the final part is fit for purpose. By choosing our sand casting service, you gain access to this application-specific engineering support, ensuring the component you receive is not just a piece of metal, but a certified solution designed for its role.

Your Partner from Concept to Delivery

Initiating a project with us is a collaborative and straightforward process designed for efficiency. It begins with your vision and drawings, which we accept in all major digital formats (IGES, STEP, DWG, etc.). Our engineering team then engages in a consultative review, offering manufacturability insights to optimize design for the sand casting process, potentially saving time and cost. We believe in clear communication from the outset, providing detailed quotations and realistic timelines—typically, sample castings can be delivered for evaluation within 10 to 20 days depending on complexity.

We stand as a reliable manufacturer committed to building long-term partnerships. Our sales and project management teams are dedicated to understanding your needs and providing high-quality, dependable sand casting solutions. We invite you to experience the difference that a focused, capable, and transparent foundry partner can make. Contact us today to discuss your specific requirements for alloy steel castings, grey iron castings, or any custom sand casting challenge, and let us provide you with a competitive quote for your high-quality components.