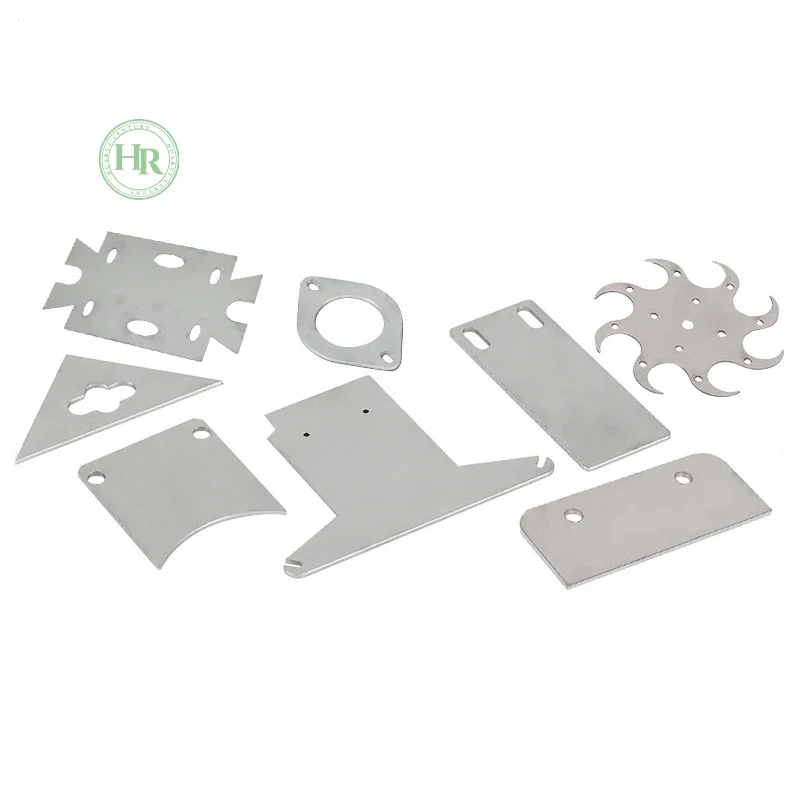

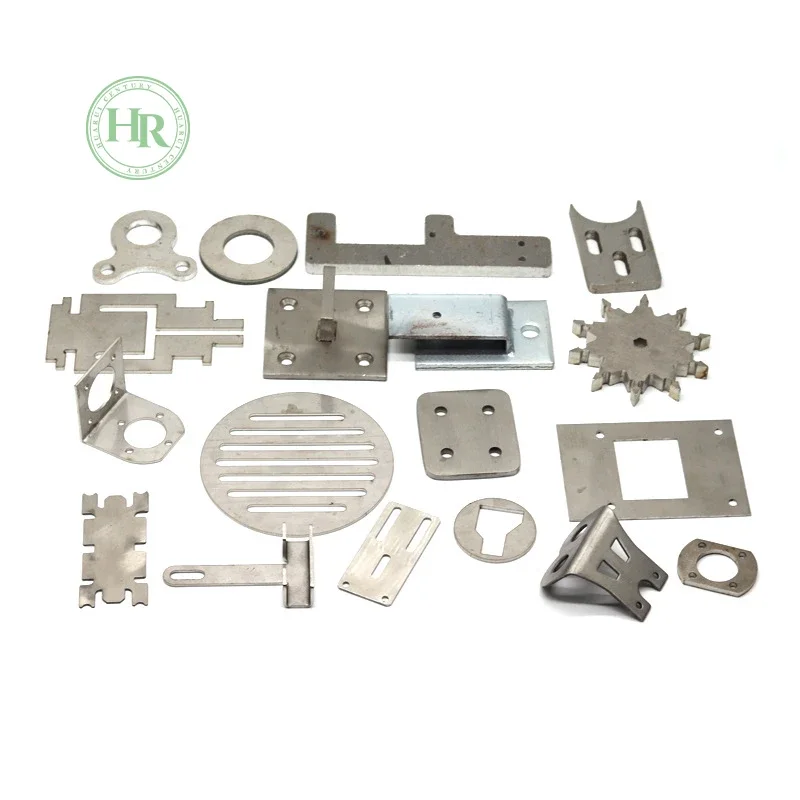

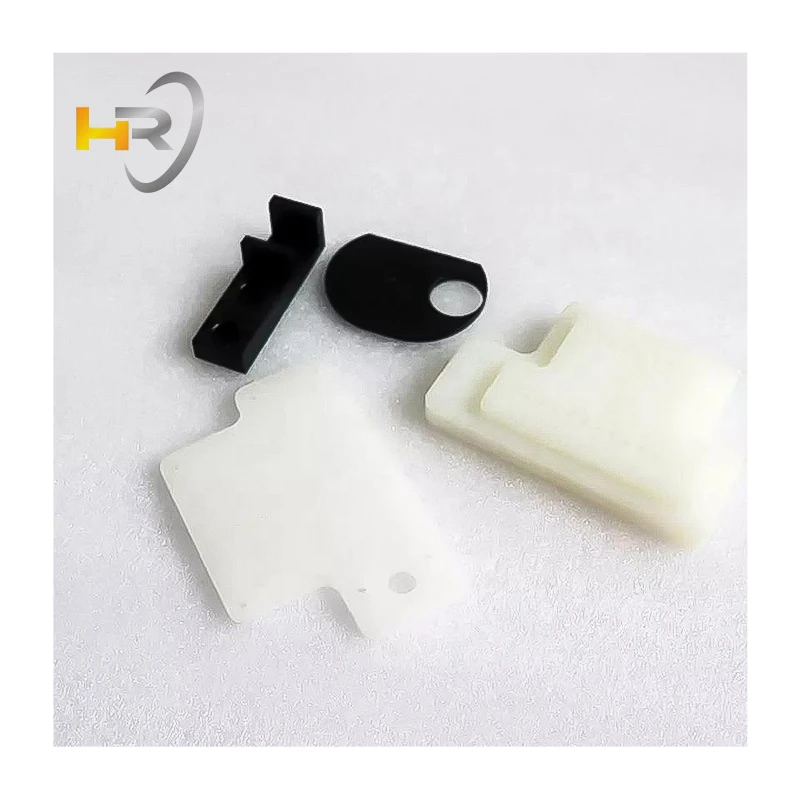

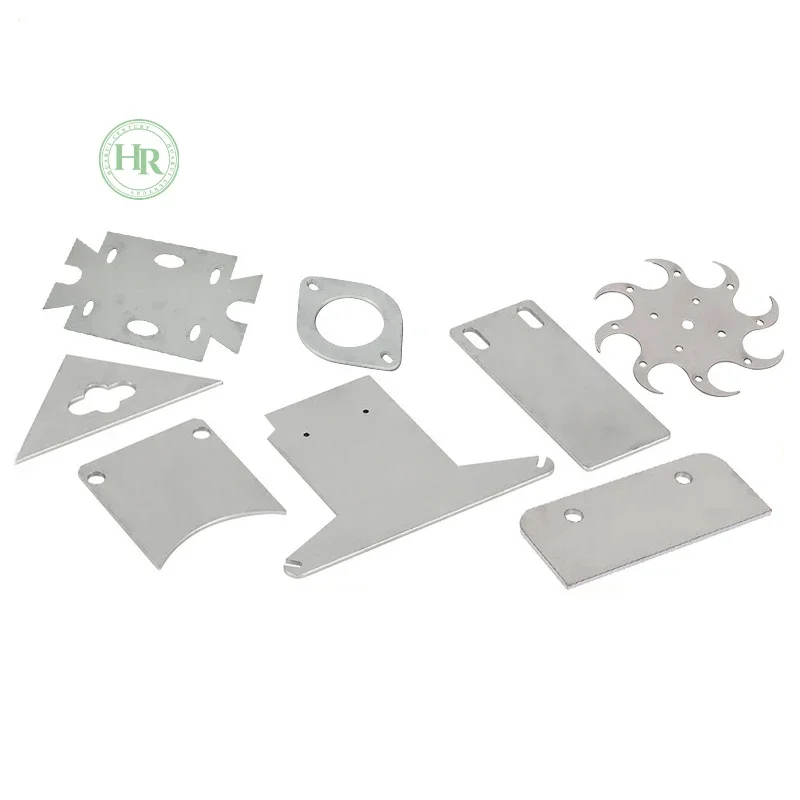

Sheet Metal Factory Custom aluminum stainless steel sheet metal fabrication laser cutting parts metal laser cutting service

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Name |

custom manufacturing sheet metal fabrication parts service |

Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Processing |

Stamping ,Sheet metal fabrication |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Our Advantages |

1.) 24 hours online service & Quickly Quote/Delivery. 2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) To provide production design, production and technical service, mould development and processing, etc |

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. is a specialized sheet metal factory providing custom aluminum and stainless steel sheet metal fabrication, including precise laser cutting parts and integrated metal laser cutting services tailored to global industrial clients. With advanced CNC laser cutting machines, automated bending cells, and professional surface finishing capabilities, we deliver high-accuracy metal components used across electronics, telecommunications, machinery, automotive, energy equipment, medical devices, and commercial applications.

Our Sheet Metal Factory Custom aluminum stainless steel sheet metal fabrication laser cutting parts metal laser cutting service is committed to transforming customer drawings into high-performance physical components with industry-leading dimensional accuracy and consistent quality. Whether producing lightweight aluminum housings or corrosion-resistant stainless steel enclosures, every part is manufactured under rigorous process controls to ensure durability, stability, and precise fit during assembly.

Key performance strengths include:

• Support for various metal materials: Aluminum, Stainless Steel, Carbon Steel, Copper, and Alloy Metals

• High-precision CNC laser cutting achieving ±0.1 mm tolerance for tight-fit functional designs

• Stable processing of thin to medium-thickness plates with minimal deformation

• Full CAD/CAM digital production from prototyping to mass manufacturing

• Smooth edges, refined detail geometry, and clean structural profiles

• Rapid lead times for both prototype iterations and high-volume batch orders

Our service model delivers not only precision sheet metal components, but also consolidated manufacturing value—faster production cycles, reduced assembly cost, and improved final product performance.

Product Performance

• High-speed laser beam processing with narrow cutting seams

• Low thermal impact ensuring visual integrity and flatness

• Suitable for complex design geometries, micro-holes, mesh structures, and intricate contours

• Data-driven control ensures repetitive consistency across every production batch

• Clean, environmentally friendly process supporting global green manufacturing trends

Product Advantages

Below are three selected advantages, deeply developed and aligned with your requirement:

Extremely High Repetitive Precision and Dimensional Consistency

Our sheet metal laser cutting systems rely on digital closed-loop positioning and advanced motion control to maintain micron-level accuracy during continuous processing. Regardless of order scale, every aluminum or stainless steel sheet metal component matches the original CAD design with outstanding repeatability. This ensures perfect interchangeability between batches, reduces manual rework, and protects final assembly tolerances, especially in industries such as electronics, instrumentation, and high-precision equipment.

Flexible Programming for Rapid Design Updates and Agile Manufacturing

The Sheet Metal Factory Custom aluminum stainless steel sheet metal fabrication laser cutting parts metal laser cutting service fully supports quick CAD modifications and instant production programming updates—without tooling changeover. Customers benefit from short new-product introduction time and seamless design iteration, making it ideal for customized industrial control boxes, mounting brackets, and specialty enclosures. This flexibility reduces engineering risk and supports business expansion through responsiveness and product innovation.

Superior Edge Quality Minimizing Secondary Finishing Cost

Our processing results feature minimal burrs and deformation, delivering smooth cutting edges ready for downstream bending, welding, or powder coating. By reducing secondary deburring and edge corrections, customers achieve shorter production cycles, lower part cost, and faster readiness for market deployment. The optical system ensures precise straight cuts and well-formed internal features, required for safety-critical components such as power distribution casings and shielding housings.

Application Scenarios

The Sheet Metal Factory Custom aluminum stainless steel sheet metal fabrication laser cutting parts metal laser cutting service is engineered for broad application across modern industrial sectors. We support diverse product types and complex assembly environments to meet professional engineering requirements:

• Electrical and Electronics: Control box enclosures, network cabinets, power distribution panels, cooling ventilation covers

• Telecommunication Equipment: 5G base station sheet metal parts, protective housings, structural mounting plates

• Industrial Machinery: Precision mechanical brackets, robotic casings, sensor mounting frames

• Automotive & Transportation: Charging station components, dashboard modules, protective stainless-steel guards

• Medical and Laboratory Devices: Structural instrument panels, clean-surface aluminum modules

• Architectural and Commercial Design: Decorative panels, stainless steel signage, ventilation screen structures

• Energy Systems: Solar inverter housings, battery storage enclosures, power-system installation boards

• Retail Automation and Kiosks: Faceplates, transaction module frameworks, steel bases

With market-proven capabilities, we help customers launch reliable, aesthetically refined products in competitive sectors where performance and precision are mission-critical.

Send Your Requirements

We welcome engineers, procurement teams, and product developers to send drawings and requirements. Our technical sales team will:

• Provide engineering recommendations for manufacturability

• Offer material selection guidance and cost optimization proposals

• Respond with pricing and lead-time details within 24 hours

• Support NDA confidentiality upon request

Please include:

-

Drawings (DXF, DWG, STEP, PDF, etc.)

-

Material grade and thickness

-

Quantity (prototypes or mass batches)

-

Surface finishing specifications

Your innovation deserves reliable manufacturing support. Contact us now to start cooperation.

FAQ – Frequently Asked Questions

What materials do you support for metal laser cutting?

Aluminum, stainless steel, carbon steel, galvanized steel, brass, and other industrial materials.

What is the maximum sheet size and thickness you can process?

Standard sheet size up to 1500 x 3000 mm; recommended thickness range 0.5–20 mm depending on material and power configuration.

Do you accept small-volume or prototype orders?

Yes. We support rapid prototype delivery and flexible quantity manufacturing to support R&D and pilot production.

Can you handle complete fabrication including bending, welding, and finishing?

Yes. We provide integrated machining services including bending, riveting, MIG/TIG welding, powder coating, anodizing, and polishing.

How do you protect surface quality during production?

Protective films, controlled clamping forces, and dedicated packaging standards are implemented to prevent scratches and ensure appearance quality.

What quality standards do you follow?

ISO-based process control, full measurement reporting, and traceability for each production batch.