Precision 5 Axis CNC Machining Service For Custom Micro Metal Parts

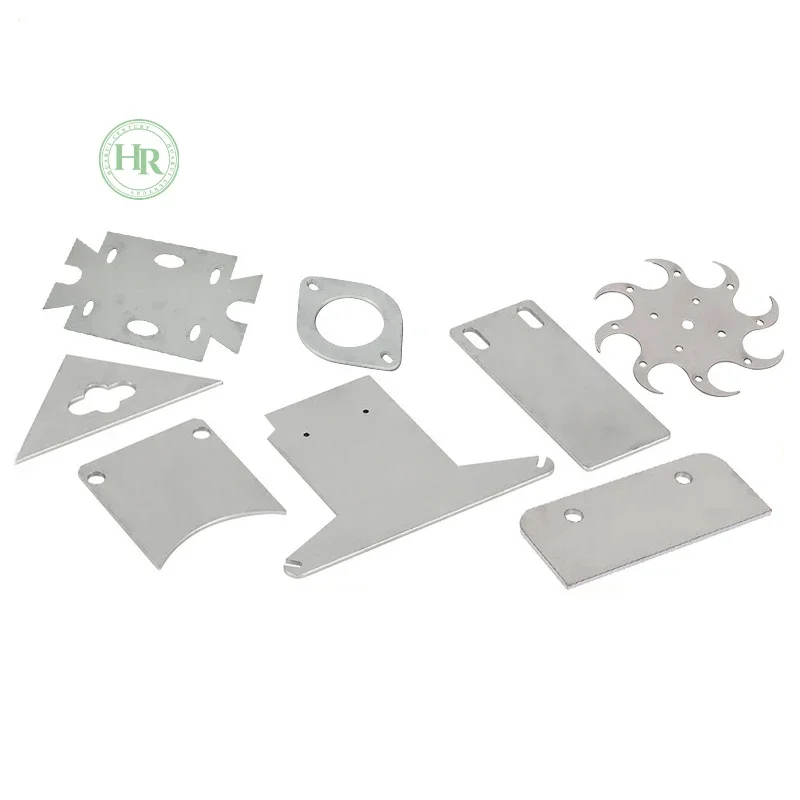

Shenzhen Huarui Century Technology delivers ultimate precision for complex, miniature components. We specialize in advanced 5-axis CNC milling and turning services, handling a wide range of materials from aluminum and stainless steel to brass die castings. Our integrated one-stop manufacturing process—from prototyping to surface treatment—ensures exceptional quality with tolerances as tight as ±0.01mm. Backed by a full suite of precision metrology equipment and comprehensive in-house capabilities, we provide reliable, custom OEM/ODM solutions for demanding industries like electronics, medical devices, and automotive engineering.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

In the realm of advanced manufacturing, the demand for smaller, lighter, and more intricate metal components continues to grow. Meeting this demand requires not just machining, but mastery. At Shenzhen Huarui Century Technology, we have honed our expertise to become leaders in the precision CNC machining of micro and geometrically complex parts. Our core offering leverages state-of-the-art 5-axis CNC machining centers, providing unparalleled freedom to manufacture sophisticated designs in a single setup. This capability is fundamental to producing the high-accuracy custom CNC workpiece that modern industries rely on. Whether you require intricate 3D micro parts for a medical device or a robust yet precise component from aluminum or brass die casting, our integrated approach ensures every specification is met with excellence.

Why 5-Axis Machining is Your Strategic Advantage for Complex Geometries

Traditional 3-axis machining has its limits, often necessitating multiple setups for parts with undercuts, deep cavities, or compound angles. Each repositioning introduces potential alignment errors and increases production time. Our 5-axis CNC machining services eliminate these bottlenecks. By allowing simultaneous movement along five axes, the cutting tool can approach the workpiece from virtually any direction. This enables us to achieve astonishing complexity and surface quality on a custom CNC workpiece that would be impossible or prohibitively expensive with conventional methods. For 3D micro parts, this technology is transformative, allowing for the fabrication of delicate features with extreme accuracy and superb finish, directly from your 3D CAD model. It is the cornerstone of our ability to deliver innovative solutions for OEM customized metal parts.

A Material Spectrum Engineered for Performance: Beyond Aluminum & Stainless Steel

Versatility in material science is a critical pillar of our service. We process an extensive portfolio of metals to match your functional, environmental, and budgetary requirements. Our proficiency with aluminum and its alloys offers an ideal solution for lightweight, corrosion-resistant components. For applications demanding superior strength and durability, we expertly machine various grades of stainless steel and steel. A key differentiator is our specialized experience with non-ferrous metals like copper and brass. We provide exceptional CNC aluminum parts and are equally adept at performing precision secondary machining on brass die casting blanks. This service is invaluable for clients who need the high-volume efficiency of die-casting combined with the tight tolerances and fine features only achievable through precision CNC machining. From alloy selections to zinc components, our material expertise ensures optimal performance.

The Micro-Fabrication Frontier: Excellence in Miniaturized Components

The production of 3D micro parts presents unique challenges—tool deflection, heat management, and precise chip evacuation must be meticulously controlled. Our CNC machining processes are specifically calibrated for micro-manufacturing. We utilize specialized tooling, high-speed spindles, and optimized cutting strategies to maintain integrity and accuracy at diminutive scales. This capability is essential for industries like electronics, where connectors and shields grow smaller, and medical technology, where minimally invasive surgical tools save lives. Every custom CNC workpiece in this category benefits from our relentless focus on micro-precision, ensuring that even the most miniature component performs its critical function reliably.

From Digital Blueprint to Physical Masterpiece: Our Integrated One-Stop Process

We are more than a machine shop; we are your comprehensive manufacturing partner. Our one-stop processing philosophy covers the entire journey of your part. It begins with our engineering team analyzing your supplied designs in formats like SolidWorks, UG, or PDF for manufacturability. The core of production involves CNC turning and milling parts, enhanced by 5-axis CNC machining for complex geometries. Supplementary processes such as precision grinding, EDM wire cutting for hardened materials or sharp internal corners, and drilling are all available in-house. Finally, we offer a variety of surface treatment options to enhance appearance, corrosion resistance, or wear characteristics. This vertical integration guarantees seamless workflow, shorter lead times, and single-point accountability for your entire project, embodying our commitment to complete OEM and ODM solutions.

Uncompromising Verification: The Science Behind Our ±0.01mm Tolerance Promise

A claim of precision is only as good as the system that verifies it. We stake our reputation on our ability to consistently hold tolerances of ±0.01mm. This commitment is underpinned by a rigorous quality control regimen and a fully equipped metrology lab. Before any precision CNC machining begins, our operators and programmers collaborate to ensure the process is capable. During and after production, a battery of advanced testing equipment is deployed. This includes CMM (Coordinate Measuring Machine) for comprehensive 3D dimensional analysis, tool microscopes for inspecting micro-features, and roughness measurement devices to quantify surface finish. Every single custom CNC workpiece undergoes a 100% QC quality inspection before delivery. A detailed quality inspection form accompanies your shipment, providing transparent, documented proof of conformity—a testament to our role as a trusted manufacturer of high-quality components.

Empowering Innovation Across Global Industries

Our precision CNC machining capabilities serve as a critical enabler for technological advancement across diverse sectors. In the electronics industry, we produce intricate CNC aluminum heat sinks and enclosures that meet stringent electromagnetic compatibility and thermal management needs. The medical industry relies on us for biocompatible, ultra-clean 3D micro parts used in diagnostic equipment and implantable devices. The automotive and motorsport fields leverage our skill in making lightweight, high-strength components from advanced alloys. Furthermore, our expertise in machining pre-formed brass die casting parts makes us a valued partner for industries requiring durable, finely finished valve bodies, fittings, and decorative hardware. As a dedicated production partner, we help translate innovative concepts into reliable, market-ready products.

Initiating Your Project: A Partnership Built on Precision and Trust

Beginning a collaboration with us is designed to be straightforward and risk-mitigated. We welcome trial orders with an MOQ of 1 piece, allowing you to validate our quality and processes firsthand. Our team offers complimentary design-for-manufacturability feedback on your 3D drawing design to optimize for cost and performance. Supported by ISO9001 certification and a decade of OEM experience, we combine technical prowess with thoughtful customer service. To discuss your specific requirement for a custom CNC workpiece, CNC aluminum component, or precision-machined brass die casting, contact our engineering sales team today. Submit your drawings for a prompt quotation and join the many international clients who rely on our manufacturing excellence in China.