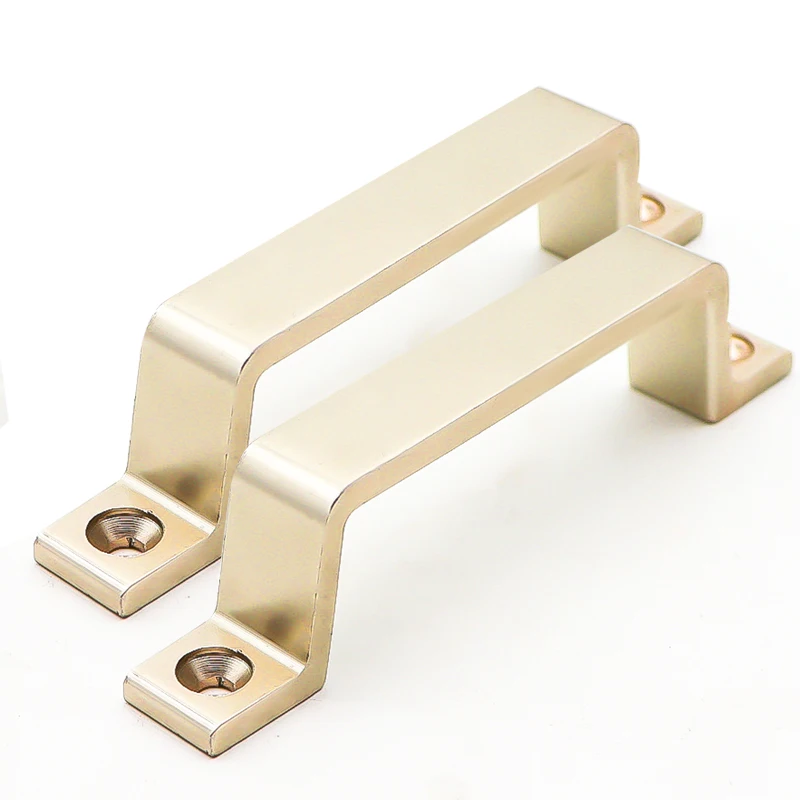

High Precision OEM ODM CNC Machining Milling Brass Parts Service

Unlock the efficiency and reliability of precision-engineered brass components with our professional CNC machining services. We specialize in manufacturing high-quality custom brass parts with exceptional tolerances as tight as ±0.01mm, perfect for prototypes and production runs starting from just one piece. Utilizing advanced CNC milling and turning centers, we transform materials like C36000 free-machining brass into complex, durable parts for industries ranging from automotive and electronics to medical devices. Backed by ISO 9001 certification, a comprehensive 100% quality inspection protocol, and full in-house capabilities from machining to surface treatment, we provide a seamless one-stop solution for your OEM and ODM project needs.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

In the world of precision manufacturing, the choice of material and machining partner is paramount. Brass, known for its excellent machinability, corrosion resistance, and electrical conductivity, is a cornerstone material for critical components across countless industries. For businesses seeking a reliable and high-quality source for custom brass parts, our CNC machining brass services offer an unparalleled combination of technical expertise, rigorous quality control, and flexible manufacturing solutions. We are not just a supplier; we are a dedicated manufacturing partner committed to transforming your designs into flawless, high-performance brass components that meet the most demanding specifications.

Why Brass is the Smart Choice for Your Precision Parts

Selecting the right material is the first step toward a successful project. Brass, particularly alloys like the industry-standard C36000, offers distinct advantages that directly translate to cost savings and part performance. Its inherent free-machining properties allow for significantly higher cutting speeds and longer tool life compared to materials like stainless steel or steel. This results in reduced cycle times and lower per-part costs, especially in high-volume production. Beyond economics, brass parts provide excellent dimensional stability, superior resistance to corrosion and wear, and natural antimicrobial properties, making them ideal for plumbing, electrical connectors, medical instruments, and marine applications. When you opt for our custom brass parts manufacturing, you leverage these material benefits alongside our process optimization to achieve optimal outcomes.

Our Core Capabilities in Precision Brass Component Manufacturing

Our manufacturing facility is engineered to deliver excellence at every stage of CNC machining brass components. We operate a dedicated suite of advanced multi-axis CNC milling and turning centers, capable of producing intricate geometries, sharp internal corners, and complex threaded features with consistent repeatability. We understand that every project is unique, which is why we offer complete OEM CNC machining and ODM support. From initial concept to final part, our engineering team collaborates with you to ensure manufacturability and performance. We accept a comprehensive range of drawing formats, including SolidWorks, UG, AutoCAD, and PDF, to seamlessly integrate with your design workflow. Our CNC machining services are built on a foundation of precision, with standard machining tolerances capable of reaching an impressive ±0.01mm, ensuring your assemblies fit perfectly every time.

A Commitment to Quality That Leaves Nothing to Chance

Quality is not an afterthought; it is the fundamental principle embedded in our precision CNC milling processes. We hold ISO 9001 and ISO 14001 certifications, a testament to our systematic approach to quality management and environmental responsibility. Every batch of custom precision CNC milling parts undergoes a rigorous 100% quality inspection before shipment. Our metrology lab is equipped with state-of-the-art equipment such as Coordinate Measuring Machines (CMM), tool microscopes, and precision height gauges to verify dimensional accuracy, surface finish (measured with roughness testers), and overall conformance to your drawings. Furthermore, we believe in transparency and partnership. We are proud to offer virtual factory tours via video call and provide detailed inspection reports with each delivery, giving you complete confidence in the quality of the brass parts you receive.

End-to-End Solutions for Diverse Industrial Applications

Our expertise in OEM CNC machining brass extends across a wide spectrum of industries, each with its own set of challenges and requirements. In the automotive and transportation sectors, we produce durable, wear-resistant components such as sensor housings, valve bodies, and decorative trims. The electronics industry relies on our CNC machining services for precision connectors, shielding enclosures, and heat dissipation modules that leverage brass's superb electrical and thermal properties. For medical device manufacturers, we machine biocompatible brass components for surgical tools and diagnostic equipment, adhering to strict hygiene and precision standards. Additionally, we serve the industrial machinery, marine, and consumer goods sectors. Our one-stop processing capability—encompassing CNC turning, milling, drilling, grinding, EDM, and various surface treatments—means you can source complex, finished brass parts from a single, accountable partner, simplifying your supply chain.

Your Partner from Prototype to Production Run

We recognize that innovation requires flexibility. That's why we have structured our CNC machining services to support your entire product development lifecycle. We actively encourage and facilitate prototype orders with a minimum order quantity (MOQ) of just one piece. This allows you to test form, fit, and function with minimal initial investment and risk. Our rapid prototyping service can often deliver sample custom brass parts within days, accelerating your time to market. As your project scales, our production lines are equipped to seamlessly transition to small-batch or high-volume manufacturing while maintaining consistent quality. We even support your long-term success with a lifetime warranty on all molds produced in our facility, ensuring ongoing reliability and cost-effectiveness for sustained production.

Initiating Your Next Project is Simple and Straightforward

Beginning your journey with a trusted precision CNC milling partner should be effortless. Our process is designed for clarity and efficiency. Simply send us your drawings or 3D models, along with your material preferences (we also work with aluminum, stainless steel, and more) and quantity requirements. Our expert engineering team will promptly review your files, provide constructive feedback if needed, and deliver a comprehensive, competitive quotation. Upon your approval, our dedicated project managers will guide your order through production, keeping you informed at every milestone. We are committed to being more than just a manufacturer; we aim to be a pivotal extension of your engineering and production team, delivering high-quality, reliable custom brass parts that empower your products' success in the global marketplace.