Precision CNC Machined Plastic Parts PEEK POM Nylon ABS PVC ±0.01mm for Prototypes

Accelerate your product development with our high-precision, custom plastic CNC machining services, perfect for rapid prototyping and low-volume production. We expertly machine a wide range of engineering plastics including PEEK, POM, Nylon, ABS, and PVC into complex, durable components with tolerances as tight as ±0.01mm. Supported by advanced CNC milling and turning centers, strict ISO-certified quality control, and a 1-piece MOQ policy, we deliver fast-turnaround solutions for the medical, automotive, aerospace, and electronics industries. From concept to functional part, trust our expertise to bring your most demanding plastic part designs to life with reliability and speed.

Introducing, the Huarui’s Custom Precision Rapid Prototype CNC Machining service for a wide range of materials including PEEK, PVC, ABS, POM, and Nylon.

With our state-of-the-art CNC milling and turning capabilities, we can create precise and high-quality plastic parts to meet your specific requirements. Our team of skilled engineers and technicians are dedicated to providing you with the best plastic CNC machining service in the industry.

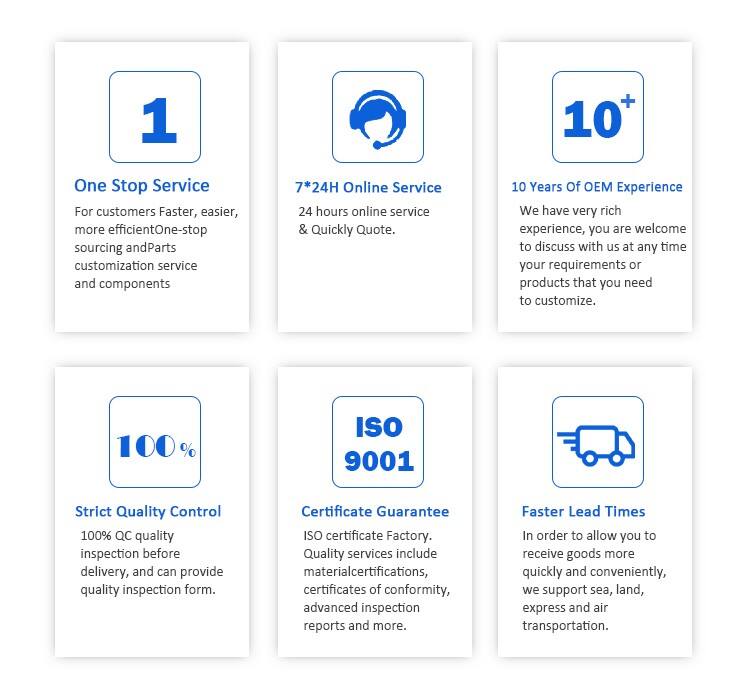

At Huarui, we understand the importance of rapid prototyping in today's fast-paced manufacturing environment. That's why we offer quick turnaround times without compromising on quality. Whether you need a small batch of parts for testing or a large production run, we can accommodate your needs with our efficient CNC machining process.

Our custom precision CNC machining service allows for intricate designs and complex geometries to be easily achieved. We can work with a variety of plastic materials to produce parts that meet your exact specifications. Our expertise in CNC milling and turning ensures that your parts will be produced with the highest level of accuracy and precision.

Quality is our top priority at Huarui. Our strict quality control measures ensure that every part we produce meets the highest standards of excellence. We take pride in delivering top-notch plastic CNC machining services that exceed our customers' expectations.

Whether you are in the automotive, medical, aerospace, or electronics industry, you can rely on Huarui for all your custom precision CNC machining needs. Our commitment to excellence, quick turnaround times, and competitive pricing make us the ideal partner for your plastic machining projects.

Trust Huarui for all your custom precision rapid prototype CNC machining needs. Contact us today to learn more about our plastic CNC machining services and how we can assist you in bringing your designs to life

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF, DWG), Solid Works, UG, CAD / CAM / CAE, PDF, TIF etc |

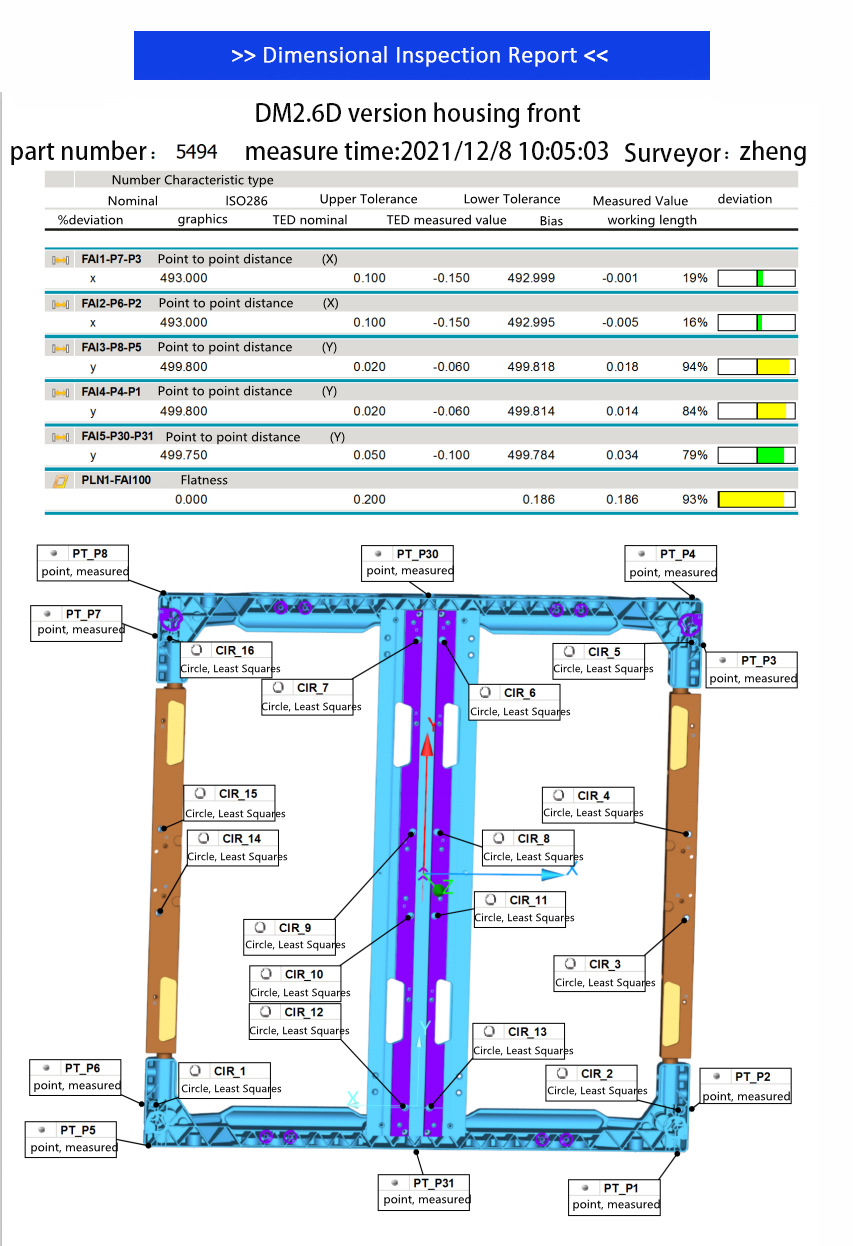

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement |

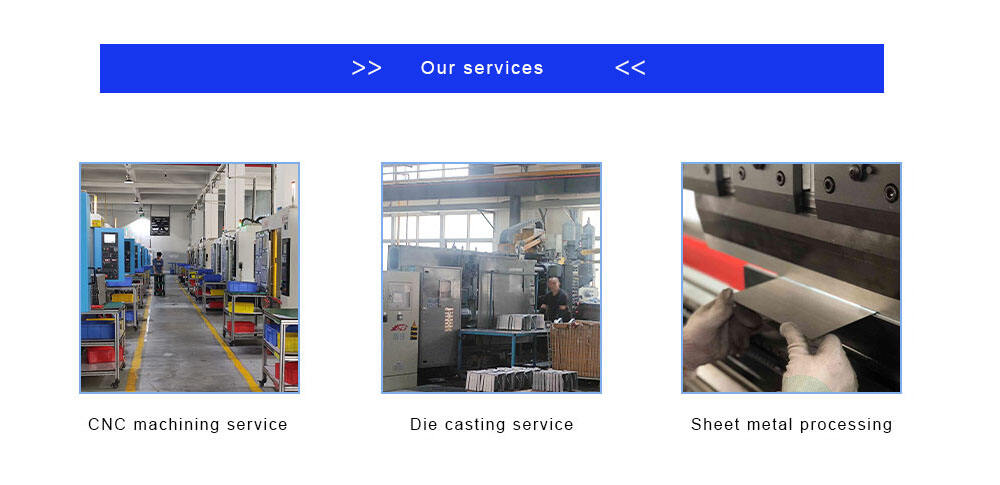

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Q1:How can I get a quote |

Detailed drawings (PDF/STEP/IGS/DWG) with material, quantity and surface treatment information |

Q2:Can you make machining parts based on our samples |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making |

Q3:Where is your factory |

A3:We are in Shenzhen, China |

Q4:Will my drawings be divulged if you benefit |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need |

Q5: Is it possible to know how are my products going on without visiting your company |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress |

In an era where innovation cycles are measured in weeks, the ability to rapidly and accurately iterate designs is a critical competitive edge. For engineers and product developers working with high-performance plastics, finding a manufacturing partner who combines material expertise with uncompromising precision is paramount. Our custom plastic CNC machining service is specifically engineered to meet this challenge, offering a seamless bridge from digital model to physical part. We specialize in transforming advanced engineering plastics like PEEK, POM, and Nylon into complex, functional components, providing an indispensable solution for rapid prototyping and pre-production validation without the cost or delay of injection molding.

Navigating the Material Landscape: Choosing the Right Plastic for Your Application

The performance of a plastic part begins long before machining, with the critical decision of material selection. Not all plastics are created equal, and their unique properties dictate their ideal applications. Our deep material science knowledge guides clients in choosing the optimal plastic for their specific needs, whether it’s the extreme thermal stability and biocompatibility of PEEK machining for medical implants, the outstanding wear resistance and dimensional stability of POM parts for precision gears, or the toughness and self-lubrication of Nylon machining for demanding mechanical components. We also proficiently handle ABS parts for robust housings and PVC machining for chemical-resistant fixtures. This consultative approach ensures your custom plastic parts are not only accurately machined but are also fundamentally fit for purpose in their end-use environment.

Beyond Speed: The True Value of Precision Rapid Prototyping

While speed is a hallmark of our rapid prototype CNC machining service, the true value lies in precision and predictability. The goal of a prototype is to obtain reliable data for design verification. Our capability to hold exceptional tolerances of ±0.01mm on machined plastics means your prototype will mirror the fit, form, and function of a final production part with remarkable fidelity. This “first-time-right” precision reduces iterative testing cycles, saves significant costs on post-processing adjustments, and dramatically shortens your overall time-to-market. By leveraging our precision CNC milling and turning services for your prototypes, you mitigate risk and make confident decisions before committing to high-cost tooling for volume production.

Mastering Complexity: From Intricate Geometries to Flawless Finishes

Engineering advancements often demand components with intricate features that push manufacturing boundaries. Our CNC machining service excels at producing complex geometries that are challenging or impossible for other processes. Utilizing multi-axis milling and precision turning centers, we expertly create thin walls, deep cavities, undercuts, fine threads, and sophisticated contours in a single setup. Furthermore, we understand that the job is not complete with machining alone. Our one-stop processing capability includes a suite of specialized surface treatments for plastics, such as fine bead blasting for a uniform matte finish, precision polishing for optical clarity, or the application of functional coatings. This comprehensive approach delivers finished, ready-to-use plastic components directly to your assembly line.

Industry-Specific Solutions: Engineered for Your Sector’s Demands

Our plastic CNC machining expertise is applied daily to solve real-world challenges across key technology sectors. In the medical industry, we machine biocompatible PEEK and sterilizable components for surgical devices and diagnostic equipment, adhering to the strictest cleanliness and tolerance standards. The automotive and aerospace sectors rely on us for lightweight, high-strength nylon and POM parts that withstand vibration and wear. For electronics, we produce insulating PVC fixtures, durable ABS enclosures, and low-outgassing PEEK insulators that ensure device reliability. This cross-industry experience means we are adept at speaking your technical language and understanding the regulatory and performance landscapes you operate within.

The Foundation of Trust: A Quality Assurance System You Can Verify

Quality in precision machining is not an aspiration; it is a measurable, verifiable output. Our commitment to quality is embedded in every step, backed by ISO 9001 certification. Each batch of custom precision plastic parts undergoes a rigorous 100% inspection before delivery, utilizing equipment like Coordinate Measuring Machines (CMM) and tool microscopes to validate dimensions against your drawings. We champion transparency and invite clients to virtual factory inspections via live video, providing a real-time view of our processes and controls. This open-book policy, combined with detailed inspection reports for every order, builds a foundation of trust and ensures you receive parts that consistently meet your highest expectations.

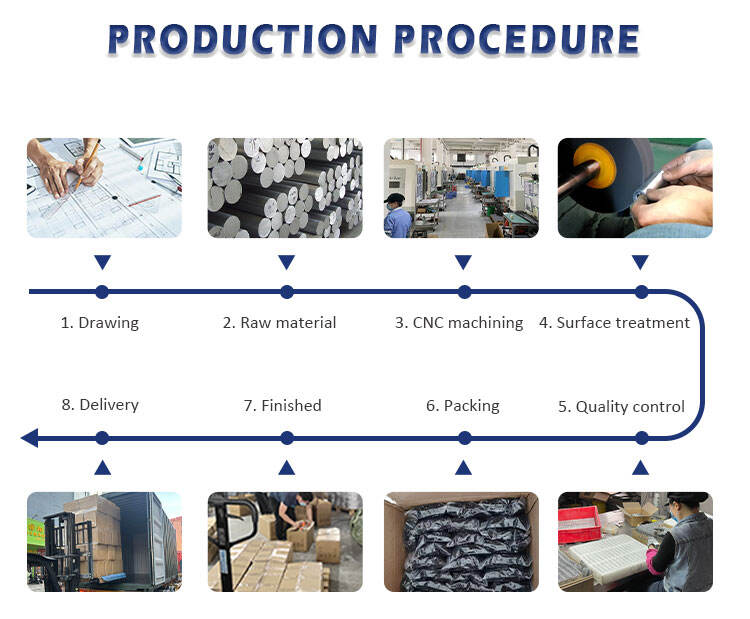

Streamlined Partnership: Your Pathway from Concept to Delivery

Initiating a project with a new manufacturing partner should be straightforward and efficient. Our process is designed for clarity and collaboration. It begins with you sharing your 3D CAD files (we support all major formats like SolidWorks and STEP) and project requirements. Our engineering team then conducts a complimentary manufacturability review, offering expert feedback to optimize your design for CNC machining. Following this, you receive a detailed, competitive quotation. Upon order confirmation, a dedicated project manager oversees production, providing updates at key milestones. We pride ourselves on being an extension of your R&D and production teams, dedicated to delivering high-quality plastic CNC machining solutions that empower your innovation and success in the global marketplace.