Precision POM Nylon PEEK CNC Machining Parts Custom OEM Engineering Plastic Components

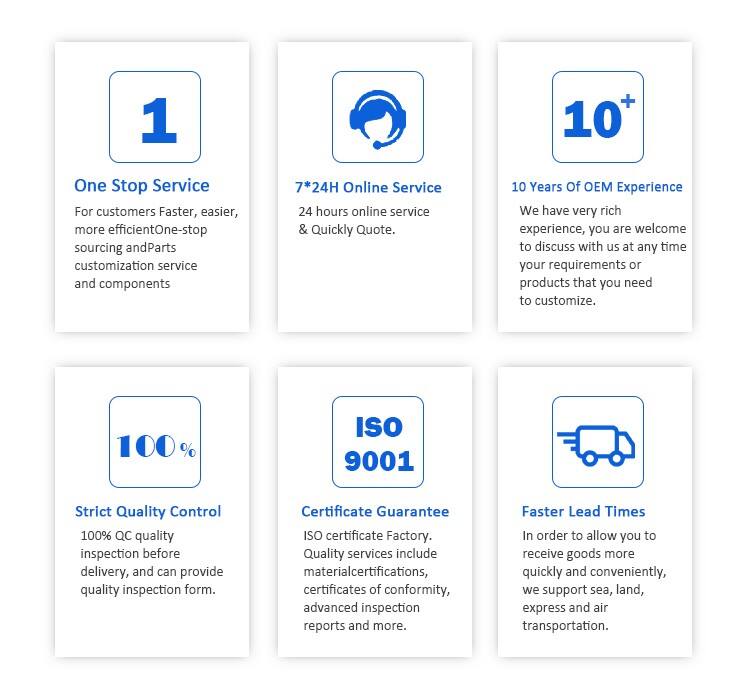

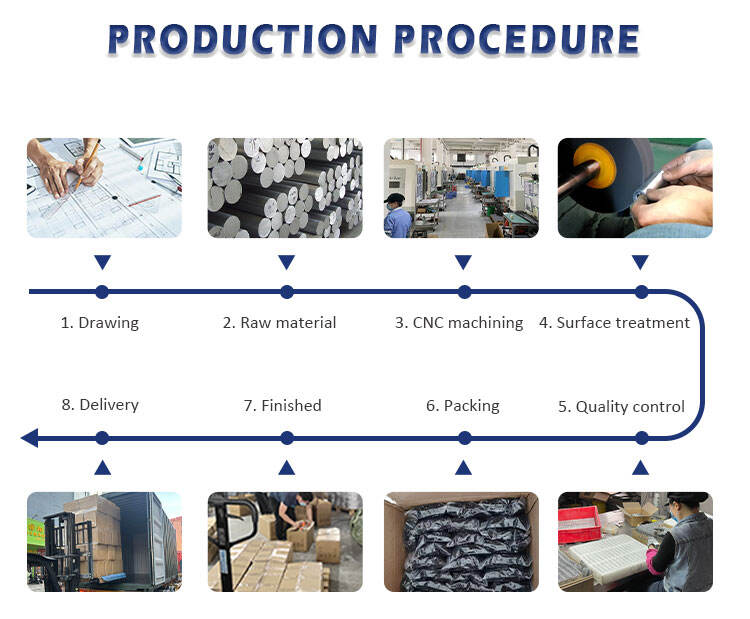

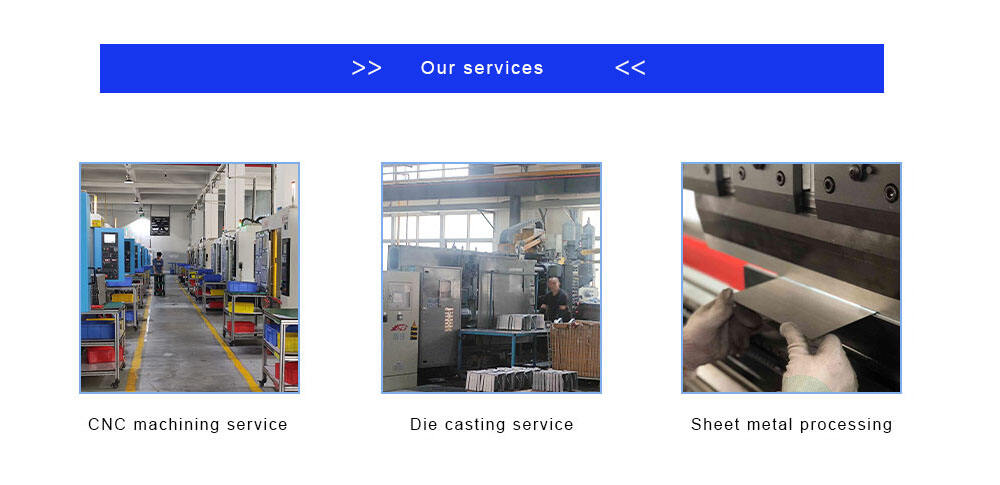

Specializing in high-performance engineering plastics, we deliver precision CNC machining services for custom POM (including Delrin), Nylon, and PEEK components. Our expertise transforms these durable materials into complex, reliable parts with tolerances as tight as ±0.01mm through advanced CNC turning and milling. Supported by material-specific machining strategies, stringent ISO-certified quality control, and a comprehensive one-stop process from prototyping to production, we provide solutions for the most demanding applications in automotive, medical, aerospace, and industrial equipment. Partner with us for parts where material properties are as critical as dimensional precision.

When you need precise and durable plastic CNC machining parts, look no further than Huarui. Our manufacturing custom CNC machining service offers OEM nylon, POM, Delrin, and PEEK CNC turning milling parts that are sure to meet your needs.

At Huarui, we use state-of-the-art equipment and technology to produce high-quality plastic CNC machining parts with precision and accuracy. Whether you need custom-made parts for industrial machinery, automotive components, or consumer electronics, we have the expertise and capabilities to deliver the exact specifications you require.

Our team of skilled engineers and machinists are experienced in working with a variety of materials, including nylon, POM, Delrin, and PEEK. These materials are known for their durability, strength, and resistance to wear and tear, making them ideal for a wide range of applications.

When you choose Huarui for your CNC machining needs, you can trust that you will receive parts that are made to last. Our attention to detail and commitment to quality ensure that each piece we produce meets the highest standards of excellence.

Whether you need a single prototype or a large batch of custom parts, Huarui can accommodate your needs. Our efficient production processes and quick turnaround times mean that you can get the parts you need when you need them.

With Huarui's custom CNC machining service, you can rest assured that your project is in good hands. Our team of experts will work closely with you to understand your requirements and provide you with the best solution for your needs.

So, why wait? Contact Huarui today to learn more about our manufacturing custom CNC machining service and how we can help you with your plastic CNC machining parts needs. With our expertise and dedication to quality, you can trust that your project will be a success

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF, DWG), Solid Works, UG, CAD / CAM / CAE, PDF, TIF etc |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Q1:How can I get a quote |

Detailed drawings (PDF/STEP/IGS/DWG) with material, quantity and surface treatment information |

Q2:Can you make machining parts based on our samples |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making |

Q3:Where is your factory |

A3:We are in Shenzhen, China |

Q4:Will my drawings be divulged if you benefit |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need |

Q5: Is it possible to know how are my products going on without visiting your company |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress |

In the world of precision manufacturing, the choice of material often dictates the success of the final component. When your design calls for the unique combination of strength, durability, and specialized properties offered by engineering plastics like POM, Nylon, and PEEK, you need more than a standard machine shop. You require a partner with deep material science understanding and the technical prowess to machine these polymers without compromising their intrinsic advantages. Our dedicated CNC machining service is built on this foundation. We specialize in the precise transformation of advanced engineering plastics into high-tolerance, functional parts, ensuring that the superior characteristics of POM, Nylon, and PEEK are fully realized in your application. This focus makes us a leading provider of custom plastic parts for industries where failure is not an option.

The Material Advantage: Why POM, Nylon, and PEEK Are Chosen for Critical Applications

Understanding why these materials are specified is key to machining them correctly. Each polymer brings a distinct set of properties to the table. POM (Polyoxymethylene), commonly known by the brand name Delrin, is renowned for its excellent dimensional stability, low friction, and high stiffness, making it ideal for precision gears, bearings, and fasteners that must perform reliably with minimal wear. Nylon (Polyamide) offers outstanding toughness, wear resistance, and self-lubrication, often chosen for demanding mechanical parts like bushings, pulleys, and seals that operate in harsh environments. At the pinnacle of performance polymers stands PEEK (Polyetheretherketone), valued for its exceptional thermal stability, superb mechanical strength retained at high temperatures, inherent flame retardancy, and biocompatibility, making it the material of choice for aerospace, medical implants, and high-performance electrical applications. Our manufacturing process is tailored to honor and preserve these critical properties.

Mastering the Craft: The Science Behind Machining Advanced Engineering Plastics

Machining these high-performance plastics presents unique challenges that differentiate it from metalworking or working with commodity plastics. Their viscoelastic behavior, lower thermal conductivity, and varied hardness can lead to issues like gumming, poor surface finish, internal stress, and dimensional inaccuracy if processed with generic parameters. This is where our specialized CNC machining service proves its value. We do not apply a one-size-fits-all approach. Instead, we have developed material-specific protocols. For Nylon CNC machining, we control the shop environment and implement post-machining conditioning protocols to manage its tendency to absorb moisture and warp. Our POM machining service employs razor-sharp, polished cutting tools and optimized feed rates to achieve clean, burr-free cuts and prevent the material from melting or adhering to the tool. For the demanding task of PEEK CNC machining, we utilize high-grade carbide tooling, precise temperature management, and customized coolants to effectively manage heat generation, thereby preserving the polymer’s coveted mechanical properties and ensuring the integrity of every CNC turning milling part.

Precision Meets Performance: Delivering Accuracy in Complex Geometries

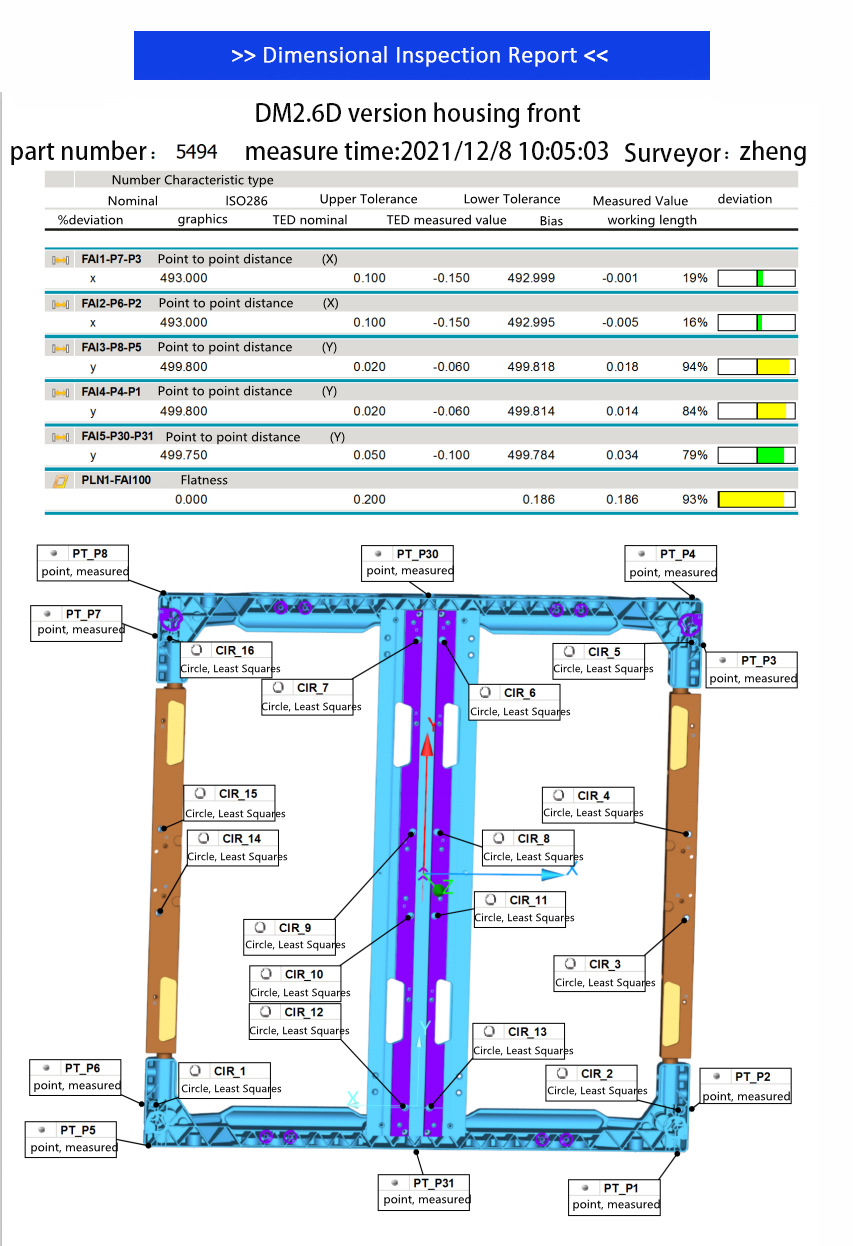

The advanced properties of these engineering plastics are frequently required in applications with zero margin for error. A medical device component or an aerospace fluid fitting must fit perfectly on the first attempt. Our commitment to precision ensures they do. Leveraging state-of-the-art multi-axis CNC turning and milling centers, our skilled programmers can machine complex geometries—from intricate contours and thin walls to deep cavities and precise threads—while holding tolerances as tight as ±0.01mm. This capability is consistently verified through a rigorous, multi-layered quality assurance process. Every batch of plastic CNC machining parts undergoes comprehensive inspection using Coordinate Measuring Machines (CMM) for dimensional accuracy and advanced surface metrology equipment to verify finish quality. We provide detailed inspection reports with each delivery, offering tangible proof that our parts meet your exact specifications for both form and function.

From Concept to Certified Component: Our Integrated Quality Assurance System

Trust is paramount when producing components for regulated and high-stakes industries. Our entire operation is anchored by an ISO 9001 certified quality management system, which ensures process control, full traceability, and continuous improvement at every stage—from initial material certification to final shipment. Our quality assurance goes beyond final inspection; it is integrated into the manufacturing workflow. We conduct in-process checks and first-article inspections to catch potential deviations early. Furthermore, we champion transparency with our clients. We offer detailed material certifications and are open to virtual factory tours, allowing you to see the controlled environment and advanced technology behind your high-quality plastic CNC machining parts. This systematic and open approach builds a foundation for long-term partnerships based on verifiable results and shared confidence in every component we produce.

Applications Engineered for Success: Industry-Specific Solutions

Our expertise in machining POM, Nylon, and PEEK directly translates into reliable solutions across critical sectors. In the medical industry, we machine biocompatible PEEK components for surgical instruments and implant trials, and sterilizable POM parts for drug delivery devices, adhering to the strictest cleanliness and tolerance standards. The automotive and aerospace sectors rely on us for lightweight, high-strength nylon gears and wear-resistant POM bushings that withstand extreme temperatures and continuous stress. For industrial and electronics applications, we produce durable Nylon insulators, low-friction POM guides, and high-temperature PEEK seals that ensure long-term equipment reliability and performance. This cross-industry experience means we not only understand your material and precision needs but also appreciate the regulatory and performance contexts in which your parts must operate seamlessly.

Your Project, Our Process: A Collaborative Path to Production

Initiating a project with a specialist in engineering plastics is designed to be a collaborative and straightforward journey. It begins with you sharing your part design and performance requirements. Our engineering team then engages in a complimentary Design for Manufacturability (DFM) analysis, providing expert feedback to optimize your part for the specific material and CNC machining process, potentially enhancing performance or improving cost-efficiency. Following this technical alignment, you will receive a clear, competitive, and comprehensive quotation. Upon project approval, a dedicated project manager becomes your single point of contact, overseeing production and keeping you informed at every milestone. As a manufacturer committed to excellence, we strive to be a true extension of your R&D and production teams, providing the material-specific expertise, advanced technology, and unwavering quality focus needed to transform your most challenging designs into dependable, high-performance reality.