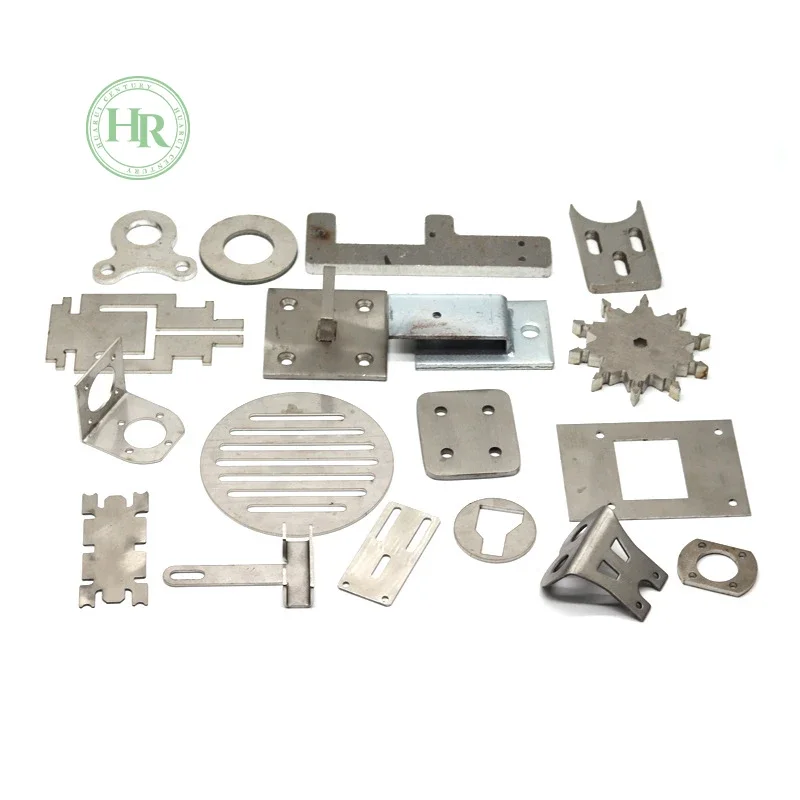

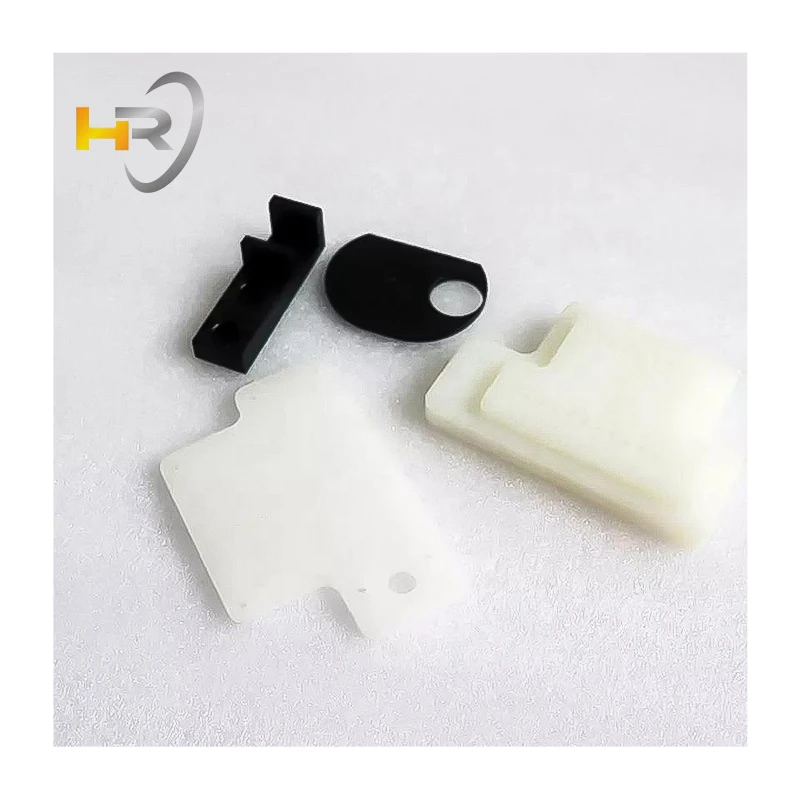

Custom aluminum stainless steel bending welding sheet metal fabrication laser cutting parts service

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Name |

custom manufacturing sheet metal fabrication parts service |

Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge; Roughness measurement |

Processing |

Stamping ,Sheet metal fabrication |

File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Our Advantages |

1.) 24 hours online service & Quickly Quote/Delivery. 2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) To provide production design, production and technical service, mould development and processing, etc |

Product Overview

Shenzhen Huarui Century Technology Co., Ltd. provides professional custom aluminum and stainless steel sheet metal fabrication services, integrating precision laser cutting, CNC bending, MIG/TIG welding, and assembly-ready finishing into a complete manufacturing solution. We specialize in delivering high-tolerance components used across industrial equipment, automation systems, consumer electronics, energy infrastructures, and mobility applications.

Our engineering and fabrication teams perform data-driven production, ensuring stable part quality, repeatable accuracy, and consistent structural performance. Through advanced automation and CAD/CAM programming integration, we deliver shorter lead times, lower scrap rates, and competitive unit pricing, even for small-batch or highly customized orders.

Performance highlights include:

-

Precision and Stability: Capable of fabricating intricate geometries while maintaining high structural integrity and dimensional stability.

-

Material Flexibility: Supports aluminum alloys, stainless steel, mild steel, galvanized steel, and copper-based metals with diverse thickness ranges.

-

High Efficiency Processing: Suitable for both prototype development and scalable mass production with rapid-cycle workflows.

-

Industry-Grade Finishing: Smooth edges, tight profile shapes, and weld reinforcement for high load-bearing applications.

By combining sheet metal artistry with advanced manufacturing, Huarui Century delivers functional and aesthetically refined metal components tailored to each customer’s specifications.

Key Advantages

Below are three featured production advantages selected from the comprehensive sheet metal capabilities:

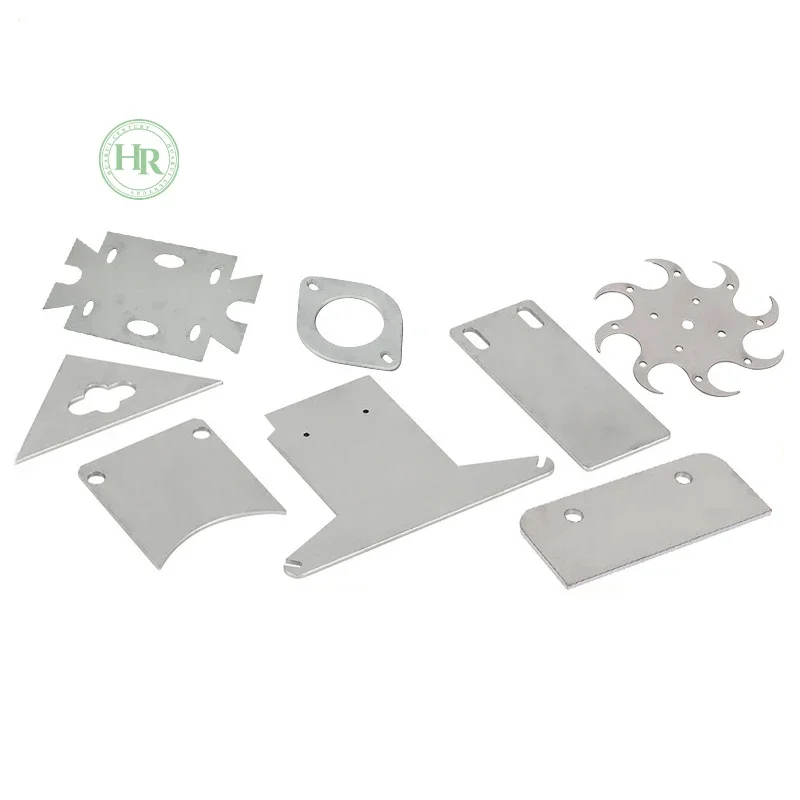

1. Excellent Edge Quality, Smooth Finishing, and Minimal Post-Processing Needed

Laser cutting ensures smooth and refined edge surfaces without burrs or tooling impressions. Even dense perforations, narrow slits, and sharp angle features retain clean boundary lines and consistent dimensional geometry. This significantly reduces secondary sanding, grinding, or trimming, helping customers minimize total processing time and cost. It also enhances assembly alignment and exterior presentation for visible components, such as housing frames and decorative panels.

2. Adaptable to Diverse Metals and Thickness Ranges with Reduced Deformation

Our process is optimized for thin to medium sheet metal thicknesses (typically 0.5–20 mm). The small heat-affected zone created during laser cutting prevents distortion, preserving the original mechanical characteristics of the material. Aluminum parts remain lightweight and corrosion-resistant, while stainless steel components retain their rigidity and surface properties. This flexibility allows us to produce both lightweight structural parts and high-strength load-bearing components in unified production lines.

3. Flexible Engineering Support for Frequent Design Changes and Prototype Iteration

Each project benefits from our intelligent CAD/CAM workflow, which makes it possible to quickly revise production drawings without tooling adjustments. This is especially advantageous for industries with rapid innovation, such as robotics, electrical systems, and customized machinery. Customers can confidently experiment with new designs while maintaining assured manufacturability. This adaptability aligns perfectly with agile development, fast prototyping, and diversified order portfolios.

Customization Process

To meet complex industrial requirements, our end-to-end custom fabrication process is optimized for precision, efficiency, and technical communication:

-

Technical Consultation & Requirement Confirmation

Our engineering team reviews customer drawings, proposes manufacturability improvements, and provides detailed quotation and lead-time planning. -

Material Selection & Specification Definition

We recommend the most suitable material grade, thickness, and finishing based on load performance, corrosion resistance, weight targets, installation environment, and batch size. -

CAD/CAM Programming & Cutting Preparation

Design files are processed through nesting optimization, minimizing raw material waste and supporting strict dimensional tolerances. -

Laser Cutting Execution

Multi-axis CNC laser systems generate accurate profiles and complex structural features with continuous real-time monitoring and data traceability. -

Precision Bending & Welding Assembly

Automated bending ensures perfect angle consistency, while professional MIG/TIG welding delivers solid joints with low distortion. -

Surface Finishing & Functional Upgrades

We provide powder coating, brushing, anodizing, passivation, and marking to achieve performance durability and branding requirements. -

Quality Inspection & Documentation Delivery

Every step is validated through CMM measuring, thickness testing, and visual inspection to meet stringent industry standards. -

Packaging & Logistics

Anti-collision protection and export-grade packing ensure that parts arrive in flawless condition for use in final assembly lines.

This controlled workflow allows clients to reduce risk, shorten development cycles, and maintain reliable supply continuity.

Request a Quote

We welcome global OEM/ODM projects involving:

-

High-precision machinery components

-

Complex enclosures and brackets

-

Welded frames and structural assemblies

-

Metal panels requiring aesthetic finishes

-

Rapid prototypes and urgent custom orders

Simply provide STEP/DWG/DXF/PDF drawings and quantity requirements.

Our team will return a 100% tailored quotation with expert technical guidance.

We are committed to delivering high-quality sheet metal parts with competitive prices, steadfast deadlines, and guaranteed performance.

Your ideas are manufacturable. Contact us to turn your design into production.

Frequently Asked Questions (FAQ)

Q1: What materials do you support?

A1: Aluminum alloys (5052/6061), stainless steel (304/316), carbon steel, galvanized steel, and copper materials.

Q2: What are your typical tolerances?

A2: With laser cutting and precision bending, we achieve ±0.1 mm tolerance depending on thickness and part complexity.

Q3: Do you provide welding and surface finishing?

A3: Yes. We offer MIG/TIG welding, riveting, and finishing including powder coating, anodizing, brushing, silk-screening, and protective films.

Q4: Can you help modify drawings for manufacturing?

A4: We offer Design-for-Manufacturing (DFM) support to improve functionality, reduce variation, and minimize cost.

Q5: How long does production take?

A5: Prototypes generally take 5–12 working days; mass production lead time depends on volume and complexity.

Q6: What quantities do you accept?

A6: From small prototypes to large-scale production, we support flexible order sizes.

Q7: Do you provide inspection data?

A7: Yes. We supply dimensional reports, welding certifications, and traceable quality documents as needed.