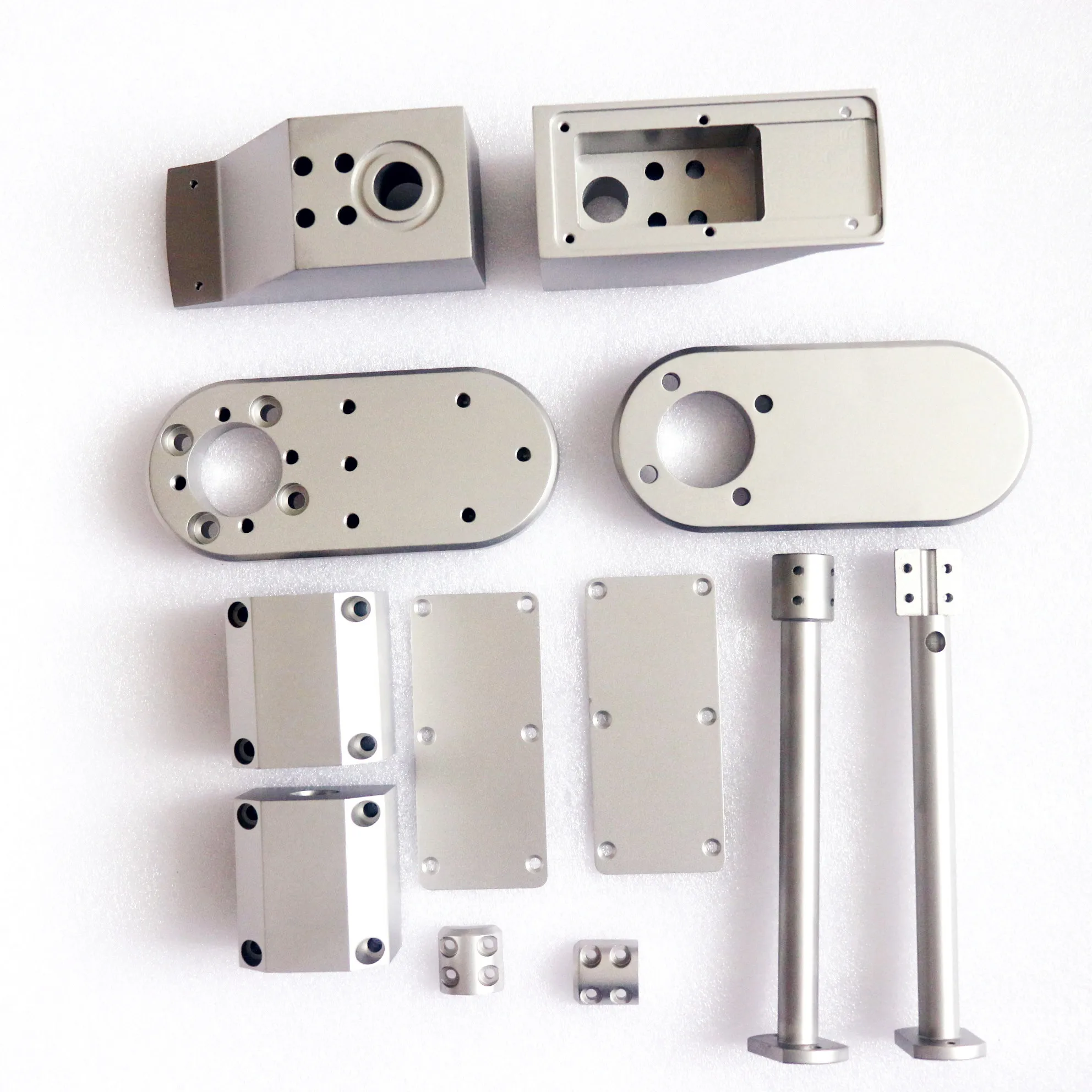

Precision Multi-Material CNC Machining Service for Aluminum and Stainless Steel Parts

Simplify complex projects with our integrated, multi-material CNC machining service. We expertly machine both aluminum and stainless steel parts, utilizing advanced CNC lathes and 5-axis turning centers to handle everything from simple turned components to complex geometries. Our one-stop solution ensures consistent high quality, streamlined communication, and cost-effective production for your assemblies requiring diverse materials. Partner with us for a reliable, single-source manufacturing experience from prototype to batch production.

Material |

Iron, Zn Alloy, Aluminum Alloy, Stainless steel, Aluminum |

Process precision |

Die casting, lathe, spring, cnc, stamping |

OEM |

Available |

MOQ |

1Pcs |

Mass lead time |

15-20 days |

Sample time |

3-7 days |

Payment terms |

T/T, L/C, Money Gram, PayPal, Crash, Western Union |

Country of origin |

Shenzhen, China |

Unify Your Supply Chain: One Partner for Aluminum, Steel, and Beyond

Modern products are rarely built from a single material. An assembly might demand the lightweight strength of aluminum alongside the corrosion resistance and durability of stainless steel. Managing multiple specialized machine shops for each material fragments your project, introducing delays, communication gaps, and quality inconsistencies. Shenzhen Huarui Century Technology offers a powerful alternative. We are your single-source provider for precision custom CNC machining across a broad spectrum of metals, with specialized expertise in both aluminum and stainless steel parts. Our integrated service consolidates your supply chain, providing seamless production, unified quality control, and a collaborative partnership that simplifies the entire manufacturing process from initial design to final delivery.

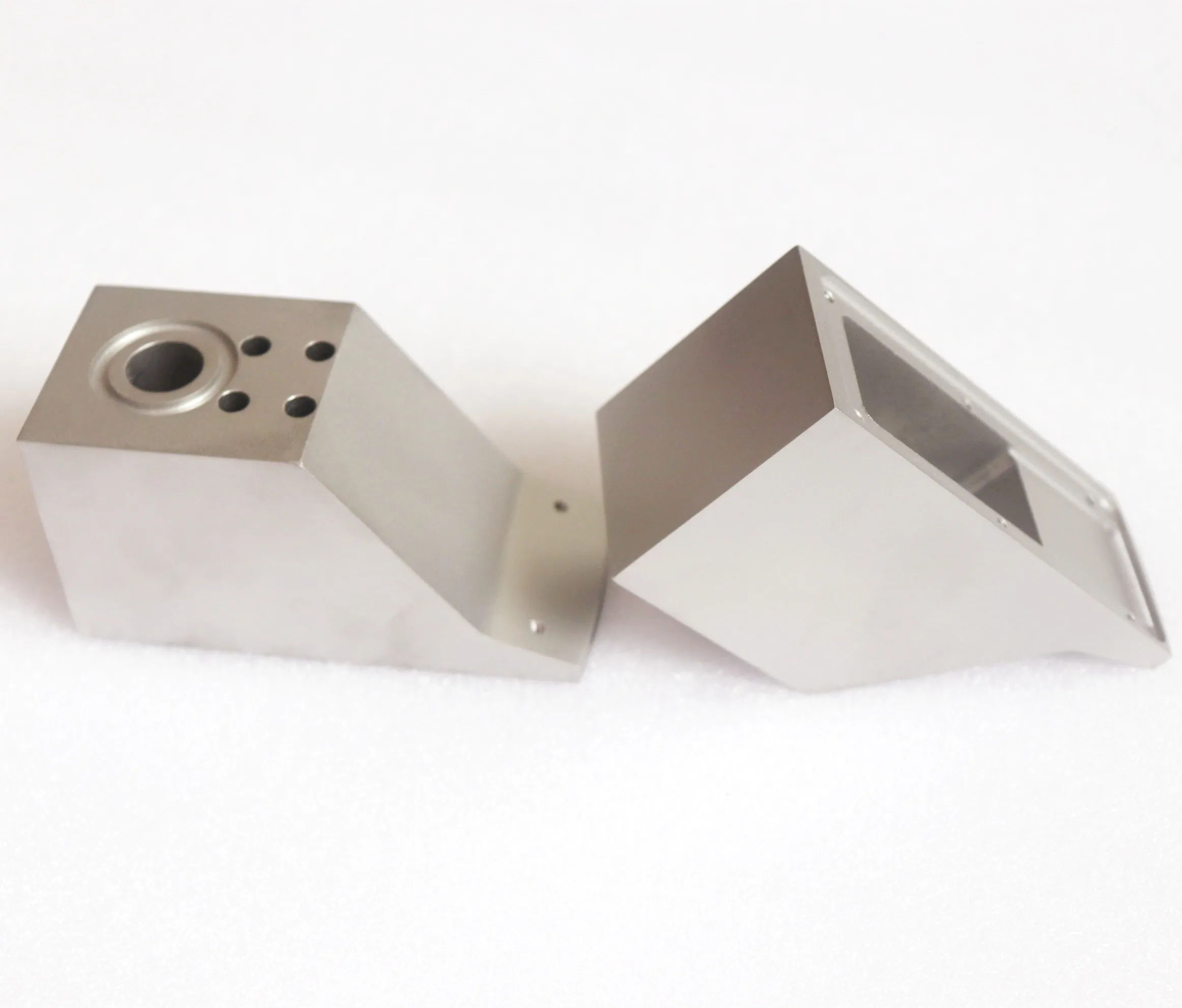

Mastering Diverse Metals: The Technical Art of Multi-Material Machining

Successfully machining different metals requires more than just changing the raw material in the machine; it demands a deep understanding of material science and adaptive machining strategies. Aluminum and stainless steel, for instance, present opposite challenges. Aluminum is soft and ductile, requiring sharp tools and specific strategies to achieve a superior surface finish without built-up edge. Stainless steel is tough, work-hardens quickly, and generates significant heat, demanding rigid setups, wear-resistant tooling, and precise control over cutting forces and coolant application.

Our decade of experience as a manufacturing partner is built upon this expertise. For your aluminum parts, we optimize for high-speed machining and flawless aesthetics. For your stainless steel parts, we employ robust parameters that ensure dimensional stability, prevent tool failure, and manage thermal stress. This material-specific mastery, applied across our CNC lathes and advanced 5-axis turning centers, guarantees that every custom metal CNC machining part—regardless of its base material—is produced to its highest potential, meeting stringent tolerances and performance requirements.

The Integrated Advantage: From Separate Parts to Finished Assembly

The true value of our multi-material service is realized in the streamlined workflow for your complete product or assembly. Consider a project requiring an aluminum housing and stainless steel internal shafts and fasteners. Traditionally, this involves two suppliers, two sets of drawings and RFQs, two quality standards, and two logistics streams. With our one-stop model, you provide one consolidated package. Our production planning team then orchestrates the entire process internally.

Your aluminum components may be machined on our high-speed 5-axis centers while your stainless steel parts are precision-turned on our CNC lathes—all within the same facility, under the same quality management system. This synchronized approach eliminates the hidden costs and risks of multi-vendor management: no conflicting lead times, no finger-pointing over fit issues, and no surprise logistics fees. It translates to faster overall project completion, lower total cost of ownership, and the peace of mind that comes from single-point accountability. This is the core of our best service promise for your custom CNC lathe and machining needs.

Precision Engineered: Leveraging 5-Axis Turning for Complex Part Challenges

For components that defy simple categorization—parts that are neither purely rotational nor purely prismatic—our 5-axis turning service provides the definitive solution. This advanced technology, often referred to as turn-mill or mill-turn machining, allows us to fabricate incredibly complex stainless steel parts and aluminum parts in a single, sophisticated setup.

Imagine a stainless steel valve body that requires precise bored holes, contoured external profiles, and off-center threaded ports. A conventional CNC lathe cannot create the off-center features. With our 5-axis turning centers, the part can be turned, then have its milling and drilling operations performed without ever leaving the chuck. This guarantees exceptional concentricity and positional accuracy between features that would be impossible to maintain across two separate machine setups. For prototypes and production runs of complex, multi-feature components, this capability is invaluable, reducing production time, eliminating fixture errors, and ensuring the highest possible part integrity. It is a cornerstone of our high-quality manufacturing pledge.

Why Choose Us as Your Multi-Material Manufacturing Partner?

Selecting Shenzhen Huarui Century Technology means choosing a partner committed to your project's holistic success through our core priorities of OEM/ODM excellence, high quality, best service, and competitive price.

Unified Quality and Consistency:

Our ISO-certified quality system applies equally to every material we machine. From incoming material inspection to final part verification with CMMs, we enforce one gold standard. You receive uniform quality across all components of your assembly, backed by comprehensive inspection reports.

Collaborative Design for Manufacturability (DFM):

Our engineers provide expert DFM feedback on all your custom metal CNC machining parts, whether aluminum or steel. We help optimize designs for cost, performance, and manufacturability specific to each material's properties, preventing costly revisions and accelerating development.

Supply Chain Simplicity and Risk Reduction:

We function as an extension of your manufacturing department. By consolidating your multi-material needs, we drastically reduce your administrative burden and supply chain complexity. You gain a reliable, long-term partner who understands your broader product goals, not just a vendor for a single part.

Proven Experience and Scalability:

With years of experience serving diverse industries, we have the expertise to navigate the challenges of multi-project production. Our flexible manufacturing setup supports everything from low-volume prototypes, allowing you to test form, fit, and function with all correct materials, to efficient, high-volume production runs.

Driving Innovation Across Industries

Our multi-material CNC machining service is instrumental in sectors where product performance depends on the intelligent integration of different materials. We manufacture precision components for:

- Automation and Robotics: Aluminum frames and enclosures paired with hardened stainless steel guide rails, gears, and actuator components.

- Medical and Dental Devices: Corrosion-resistant stainless steel surgical instruments and implants alongside lightweight, anodizable aluminum equipment housings.

- Aerospace and Defense: High-strength aluminum structural elements integrated with durable stainless steel fittings and fasteners.

- High-Performance Consumer Products: Combining the aesthetic appeal of machined aluminum with the strength and feel of stainless steel accents.

Begin Your Simplified Manufacturing Journey

Initiating a project is designed for efficiency. Share your CAD files and requirements with our team. We will analyze your multi-material needs and provide a clear, consolidated quotation and project plan. Upon approval, we manage all aspects of production internally, keeping you informed with streamlined communication. Experience the confidence and efficiency that comes from a true single-source manufacturing partner. Contact us today to discuss how our comprehensive custom CNC machining service for aluminum and stainless steel parts can bring your integrated product vision to life.