sheet metal manufacturer customized OEM metal sheet fabrication services STAINLESS STEEL STAMPING PARTS

| Item | Details |

|---|---|

| Place of Origin | Guangdong, China |

| Brand Name | HR |

| Product Type | Laser Cutting / Stamping / Bending Parts |

| Material | Stainless Steel / Aluminum / Cold Rolled Steel / Galvanized Steel |

| Size & Thickness | Customized per Drawings |

| Tolerance | As Required |

| Surface Treatment | Optional per Request |

| Certificate | ISO9001 |

| Packaging | Customized |

Material |

Iron, Zn Alloy, Aluminum Alloy, Stainless steel, Aluminum |

Process precision |

Die casting, lathe, spring, cnc, stamping |

OEM |

Available |

MOQ |

1Pcs |

Mass lead time |

15-20 days |

Sample time |

3-7 days |

Payment terms |

T/T, L/C, Money Gram, PayPal, Crash, Western Union |

Country of origin |

Shenzhen, China |

Product Overview

Product Introduction

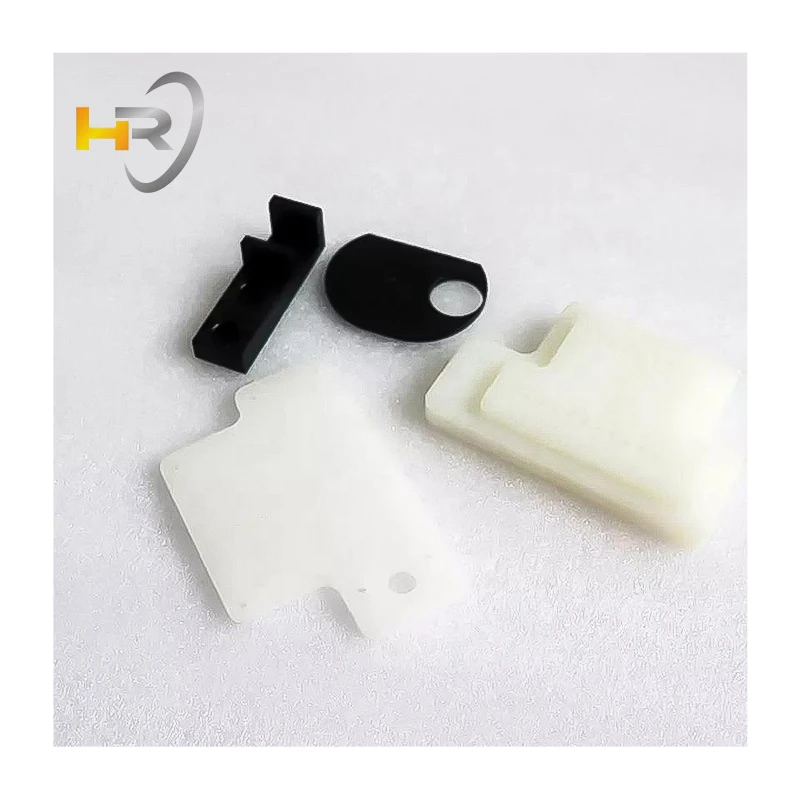

Shenzhen Huarui Century Technology Co., Ltd. is a premier OEM provider of custom sheet metal fabrication, specializing in stainless steel stamping parts. Our services cater to a wide range of industries, including automotive, electronics, industrial machinery, and consumer appliances, providing high-precision, reliable components that meet stringent quality standards.

We offer advanced stamping, bending, and forming solutions for thin to medium-thickness sheet metals, producing parts such as enclosures, brackets, clips, and functional assemblies. Our deep knowledge of material properties allows us to handle stainless steel, aluminum, copper, and low-carbon steel with equal precision, ensuring structural integrity and durability across diverse applications.

Product Performance Attributes

-

High Dimensional Accuracy: Every part is manufactured under strict tolerance control, ensuring uniformity in both small prototype runs and large-scale production.

-

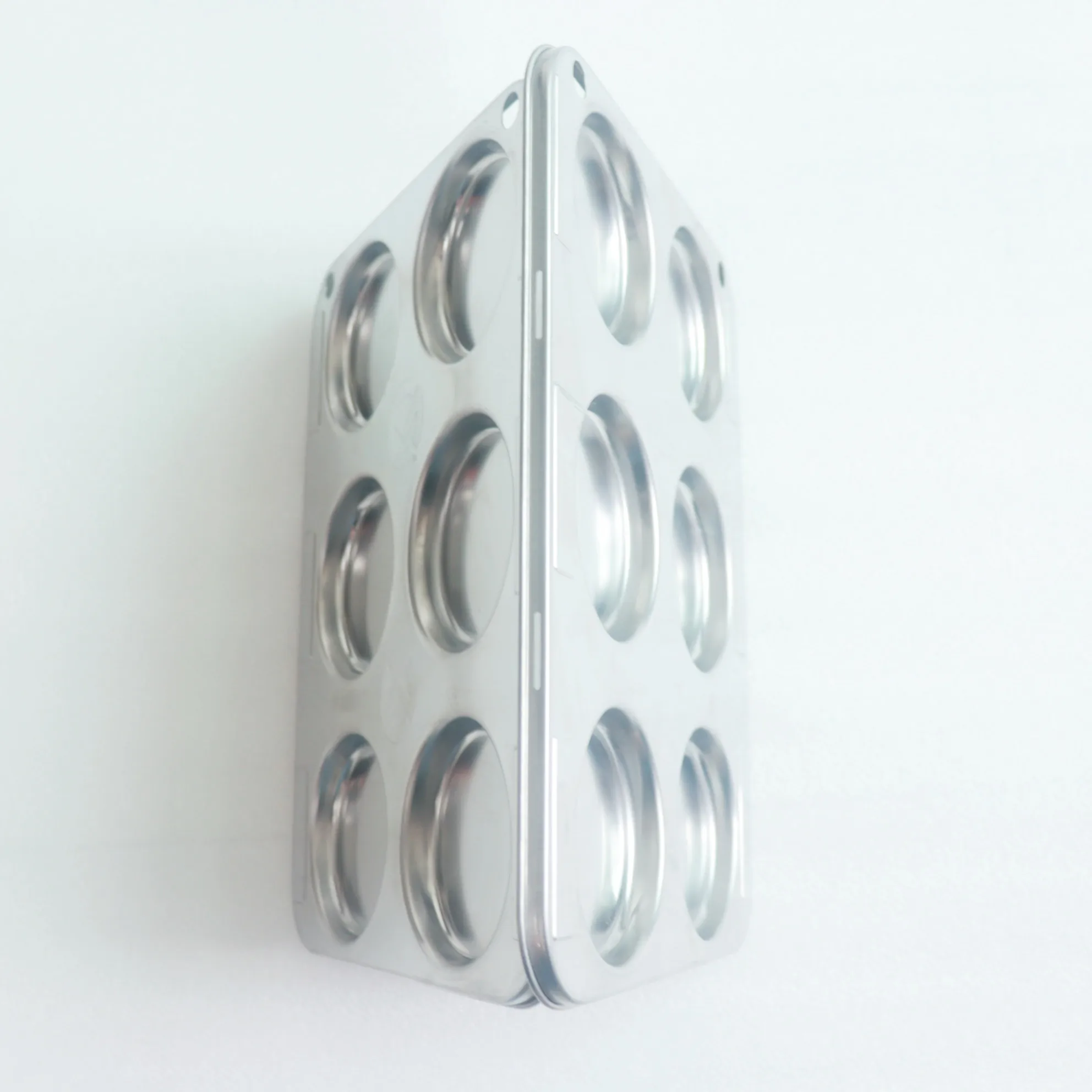

Complex Geometries: Our stamping and deep drawing processes can form three-dimensional components with ribs, flanges, hems, and embossed features in a single operation, reducing the need for secondary assembly.

-

Surface Integrity: Tooling-driven forming ensures smooth, burr-free surfaces suitable for plating, coating, or direct assembly.

-

Versatile Material Handling: Capable of processing thin foils up to plates typically ≤6mm, allowing flexibility for diverse engineering requirements.

-

Scalable Production: Whether producing small batches or high-volume runs, we maintain consistent quality, making our services suitable for both prototyping and mass production.

Our OEM sheet metal fabrication solutions combine precision, strength, and efficiency to provide tailored metal components for demanding industrial and commercial applications.

Product Advantages

1. High Production Efficiency

Our stamping and sheet metal fabrication lines integrate multiple operations, including punching, bending, and forming, into continuous workflows. Automated material handling and progressive dies allow rapid production while maintaining consistent part quality. This high production efficiency supports large-scale orders with minimal lead times, optimizing delivery for time-sensitive projects.

2. Exceptional Precision and Consistency

We specialize in manufacturing small, intricate components that require high repeatability. Advanced tooling and process control ensure that every part meets tight tolerances and functional specifications. This precision is critical for applications such as electronic housings, mechanical assemblies, and structural parts where exact dimensions affect performance and reliability.

3. Cost-Effective Large-Scale Manufacturing

Through optimized nesting, progressive die operations, and automated workflows, we maximize material usage while minimizing waste. This approach reduces per-unit costs in high-volume production. By consolidating multiple operations into single press cycles, labor requirements and processing time are reduced, allowing competitive pricing without compromising part quality or structural performance.

These advantages make our stamping and sheet metal services ideal for industries requiring precise, high-volume, and cost-effective metal components.

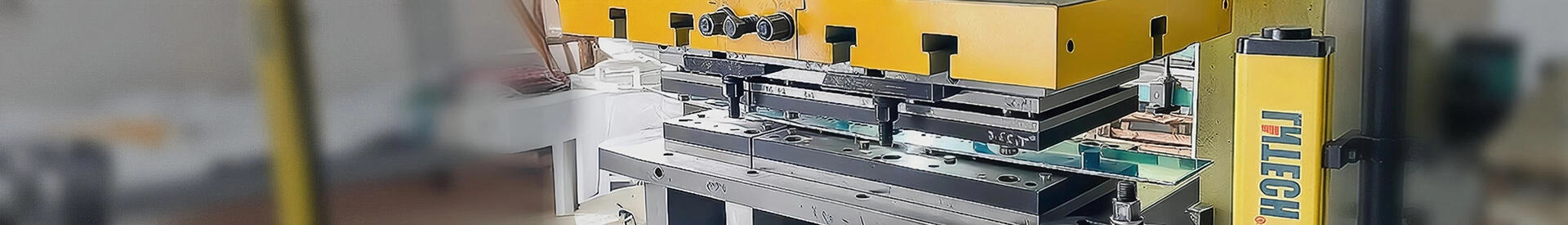

Production Process

Standardized Fabrication Workflow

Our production process ensures consistent quality, precision, and efficiency from prototype to mass production:

-

Design Consultation and Feasibility Review

Clients submit technical drawings and material specifications. Our engineering team evaluates feasibility, recommends design optimizations, and ensures manufacturability for cost-effective and structurally sound components. -

Tooling and Die Development

Custom dies are designed using simulation tools to achieve precise feature formation, accurate dimensions, and minimal material stress. Test runs verify surface quality and compliance with design specifications. -

Prototype Production and Validation

Sample parts are manufactured and inspected using coordinate measuring machines (CMM) and visual checks. Prototypes confirm dimensional accuracy, surface finish, and functionality before full-scale production. -

Full-Scale Production

Automated stamping presses and progressive dies support uninterrupted production, maintaining high precision and consistent quality across batches. Inline inspections and monitoring ensure defect-free components. -

Post-Processing and Surface Finishing

Optional secondary processes such as deburring, polishing, plating, and coating are applied based on client requirements, enhancing appearance and functional properties. -

Final Inspection and Packaging

Each batch undergoes rigorous quality control to meet specified standards. Components are securely packaged for safe transport and delivery, ensuring reliability upon arrival.

This process ensures that every stamped component is consistent, traceable, and ready for integration into high-performance assemblies.

Buyer Inquiry Recommendations

To obtain a precise quotation and production plan, please provide:

-

CAD or technical drawings (STEP, IGES, or PDF formats)

-

Material type, thickness, and any coating requirements

-

Surface finish and post-processing instructions

-

Functional specifications and tolerance requirements

-

Estimated order quantity and expected production frequency

Our expert engineering team will evaluate your specifications, suggest optimizations, and provide a competitive quote. Contact us today to leverage our high-precision sheet metal stamping services, fully customized for your production needs.

Frequently Asked Questions (FAQ)

Q1: What types of materials can you process?

We handle stainless steel, aluminum, brass, copper, and low-carbon steel sheets.

Q2: Can you produce complex 3D geometries?

Yes. Our deep drawing and stamping capabilities allow ribs, hems, flanges, and embossed features in a single operation.

Q3: What tolerances can be achieved?

Our processes allow tight tolerances depending on material thickness and part complexity, typically within ±0.1mm for most components.

Q4: Are prototypes available before mass production?

Yes. We provide prototype samples to validate design feasibility, fit, and performance.

Q5: Do you provide surface finishing?

Yes. Options include deburring, polishing, plating, coating, and anodizing to meet client specifications.

Q6: Can you produce both small and large batches?

Yes. Our automated stamping lines and progressive dies ensure precision and repeatability across any production volume.

Q7: Do you offer international shipping?

Absolutely. We provide secure packaging and reliable logistics for worldwide delivery.

Q8: How long is the typical lead time?

Lead times vary with complexity and batch size. Standard orders typically range from 3–6 weeks.

Q9: Can design modifications be implemented after production begins?

Changes post-tooling may require additional costs. Finalizing designs during the prototyping phase is recommended to avoid extra expenses.