Precision Custom 5-Axis Aluminum CNC Machining Parts High Speed Milling Service

Achieve superior quality and efficiency in volume production with our advanced precision aluminum CNC machining service. We specialize in high-speed 5-axis milling of complex components, guaranteeing tolerances as tight as ±0.01mm. From your CAD design to the final finished part, Shenzhen Huarui Century Technology provides a complete one-stop solution including expert surface treatments like anodizing and polishing. Our process is engineered for exceptional accuracy, minimal part deformation, and flawless aesthetics, making it ideal for demanding applications in automation, telecommunications, and consumer electronics.

| Craft | Customized OEM cnc machining milling turning parts service |

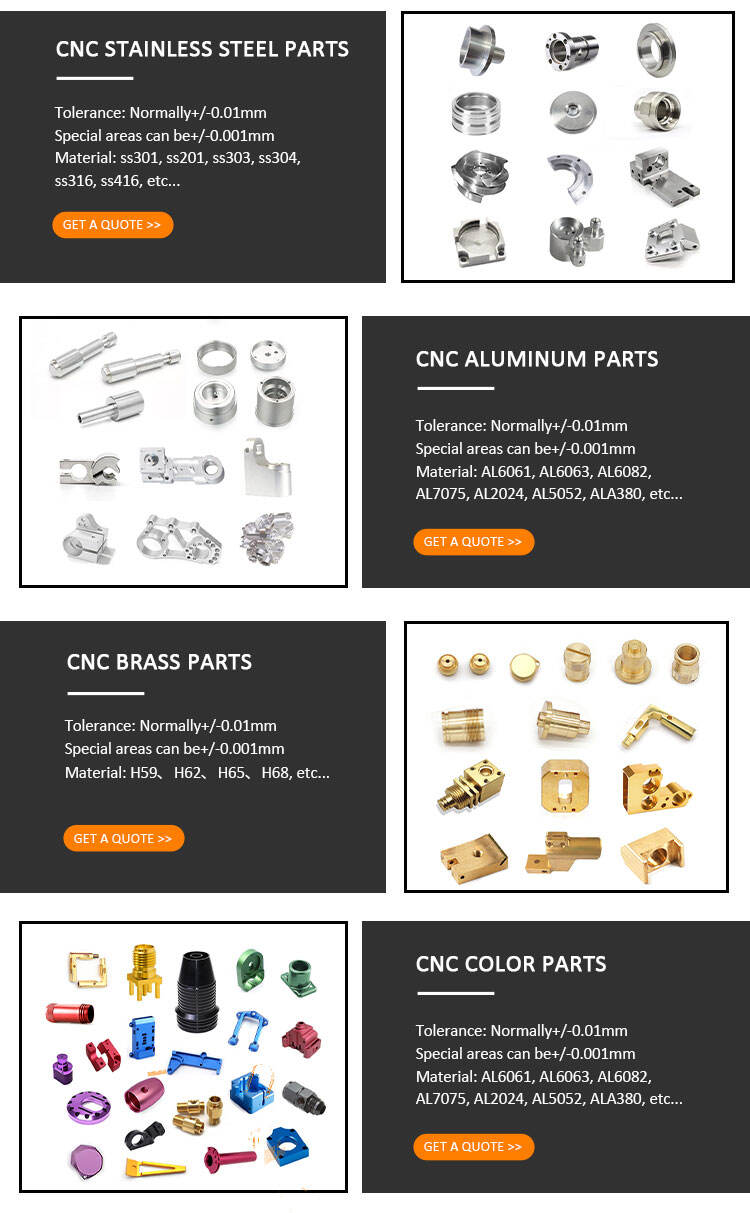

| Available materials | Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

| Drawing Formats | PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

| Testing Equipment | CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

| One stop processing | CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

| Tolerance | +/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

Redefining Production Excellence: Where Unmatched Precision Meets Efficiency

In today's competitive landscape, manufacturing success hinges on more than just making parts—it demands making them flawlessly, consistently, and efficiently. Standard machining often forces a compromise between speed, cost, and the critical precision required for high-performance aluminum components. Shenzhen Huarui Century Technology eliminates this compromise. Our dedicated precision aluminum CNC machining service leverages advanced high-speed 5-axis technology to deliver components that excel in both dimensional accuracy and structural integrity. We focus on transforming complex designs into high-volume reality, ensuring every piece, from the first to the thousandth, meets the most stringent specifications for advanced industries.

The Engine of Perfection: High-Speed 5-Axis Machining Explained

The core of our capability lies in the sophisticated synergy between simultaneous 5-axis machining and high-speed milling (HSM) strategies. This combination is transformative for producing precision aluminum parts. The 5-axis capability allows us to machine intricate geometries, deep cavities, and complex contours in a single setup, drastically reducing cumulative errors. Simultaneously, our high-speed machining protocols utilize elevated spindle speeds and optimized feed rates. This approach reduces cutting forces by over 30% compared to conventional methods, which is critical for preventing distortion in thin-walled or delicate aluminum components. The result is not just the achievement of ±0.01mm tolerances, but also exceptionally smooth surface finishes directly from the machine, reducing the need for extensive secondary finishing. This methodology is what sets our CNC machining service apart for projects where micro-level accuracy and consistency are non-negotiable.

From Digital Concept to Tangible Masterpiece: Our Integrated Workflow

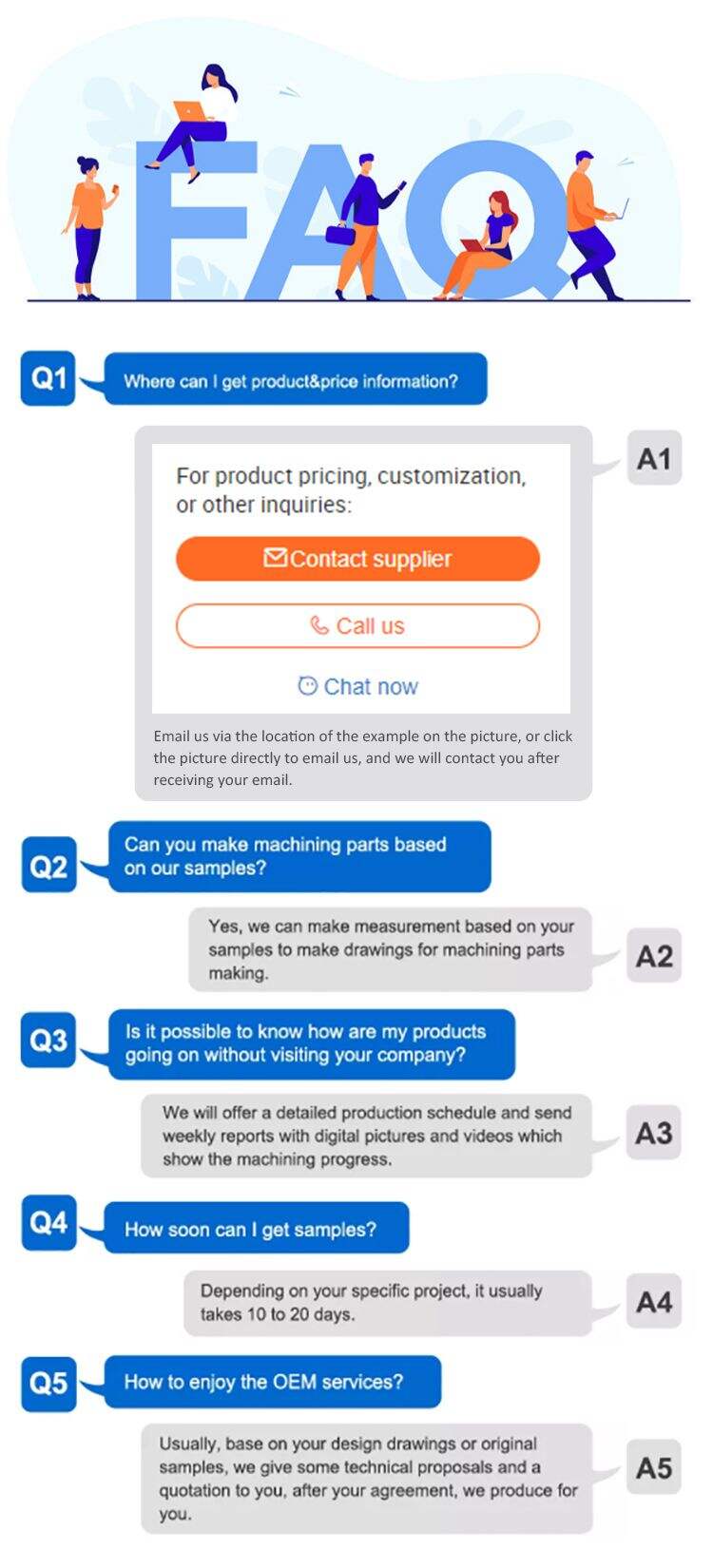

Your journey with us is a seamless, transparent partnership engineered for reliability. It begins with your vision. Our engineering team collaborates with you from the earliest stage, accepting all major CAD formats for a comprehensive Design for Manufacturability (DFM) analysis. This proactive step, honed over a decade of OEM and ODM experience, optimizes your design for the high-speed milling process, identifying opportunities to enhance strength, reduce weight, and ensure cost-effective production.

We then select the ideal aluminum alloy from our extensive inventory to meet your specific mechanical and aesthetic goals. The manufacturing phase is where our precision CNC machining expertise comes to life on our advanced 5-axis platforms. However, our service extends far beyond milling. As a true one-stop provider, we integrate all necessary post-processing in-house, including precision turning, drilling, and a comprehensive suite of surface treatments. Each custom aluminum part undergoes a rigorous 100% quality inspection using advanced equipment like Coordinate Measuring Machines (CMM), providing documented verification that every dimension adheres to your blueprint.

Surface Finishing: The Final Touch of Quality and Durability

A component's performance is often defined by its surface. We offer a full spectrum of finishing services to add functional and aesthetic value to your precision aluminum parts. Our expertise includes:

Anodizing: We apply controlled electrolytic passivation to increase surface hardness, enhance corrosion resistance, and provide a durable, substrate for coloring.

Polishing & Brushing: From achieving a mirror-like reflective finish to creating a uniform satin texture, we refine surfaces to meet exact visual and tactile specifications.

Sandblasting: This process creates a uniform matte finish, masks minor tooling marks, and provides an excellent base for painting or coating.

Plating: For applications requiring specific electrical properties or additional wear resistance, we offer expert electroplating services.

Our finishing specialists help you select the perfect treatment to ensure your parts are not only precisely machined but also finished to the highest commercial and industrial standards.

Why Partner with Shenzhen Huarui Century Technology?

Choosing a manufacturing partner is a strategic decision. Here’s why leading brands trust us with their most critical precision aluminum components:

A Decade of Specialized Mastery: Our ten-year focus on high-tolerance CNC machining has equipped us with deep, practical knowledge to navigate manufacturing challenges and deliver reliable, innovative solutions for volume production.

Commitment to Quantifiable Quality: Our promise is backed by a systematic approach. We maintain an exceptional 99.99% product qualification rate through an ISO 9001-certified quality management system and stringent in-process inspections, ensuring consistent excellence.

Engineered for Production Agility: We understand the market's pace. Our production model is designed for flexibility, seamlessly scaling from rapid prototyping with minimal lead times to stable, high-volume manufacturing runs without compromising our stringent quality controls.

End-to-End Accountability and Simplicity: By consolidating the entire process—from initial design review and precision 5-axis machining to advanced surface treatment and final certification—under one roof, we simplify your supply chain, reduce risks, and become your single point of contact for manufacturing success.

Driving Innovation Across Industries

The capabilities of our precision aluminum CNC machining service are pivotal across multiple sectors. We manufacture robust, lightweight structural frames and actuator components for the automation and robotics industry, where precision directly impacts performance. In telecommunications, we produce intricate, thermally efficient housings for sensitive electronic equipment. Furthermore, our ability to deliver parts with superior cosmetic finishes makes us a preferred partner for high-end consumer goods, where aesthetics and feel are as important as function.

Begin Your Project with a Trusted Manufacturer

Starting a project with Shenzhen Huarui Century Technology is straightforward. Contact our engineering team with your drawings or concepts. We will provide a prompt, detailed quotation and a collaborative DFM review. Upon approval, we proceed to precision programming and produce first-article samples for your verification. After your confirmation, we move into full production with constant communication, ensuring your order is delivered on time, to specification, and with the quality you expect. Let’s discuss how our precision CNC machining service can advance your production.