Precision Custom OEM Aluminum Fabrication Parts ±0.01mm Tolerance

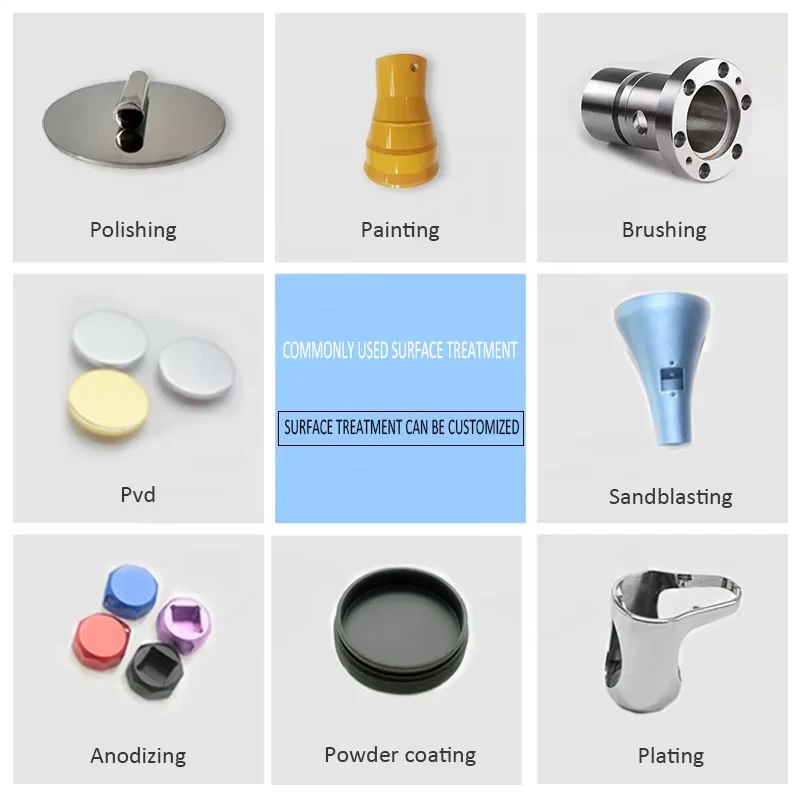

Meet your most demanding project requirements with our comprehensive, one-stop aluminum fabrication service. We expertly transform your designs into high-precision, finished components through integrated CNC milling, turning, and complementary processes like EDM. Each custom aluminum fabrication part is manufactured to exacting ±0.01mm tolerances and can be enhanced with a full suite of customizable surface treatments including anodizing, powder coating, and PVD. Partner with our experienced team for a seamless, quality-guaranteed journey from prototype to production run.

Craft |

Customized OEM cnc machining milling turning parts service

|

Available materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Drawing Formats |

PRO/Engineer, Auto CAD(DXF,DWG), Solid Works , UG, CAD / CAM / CAE, PDF,TIF etc. |

Testing Equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement. |

One stop processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Grinding, EDM wire cutting, Surface Treatment, etc. |

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form. |

You are very welcome to visit us among many suppliers

Q1:How can I get a quote? |

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information. |

Q2:Can you make machining parts based on our samples? |

A2:Yes, we can make measurement based on your samples to make drawings for machining parts making. |

Q3:Where is your factory? |

A3:We are in Shenzhen, China. |

Q4:Will my drawings be divulged if you benefit? |

A4:No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need. |

Q5: Is it possible to know how are my products going on without visiting your company? |

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

From Complex Blueprints to Flawless Reality: Your Complete Manufacturing Partner

Modern engineering demands more than just machining—it requires a holistic approach to fabrication. When your design calls for a sophisticated aluminum component that integrates multiple features, tight tolerances, and a specific finish, managing disparate suppliers becomes a major bottleneck. Shenzhen Huarui Century Technology provides the definitive solution. We are your dedicated source for complete aluminum fabrication parts, offering an integrated manufacturing service that manages the entire process from raw material to ready-to-install component. Our expertise lies in delivering not just machined pieces, but fully realized custom aluminum parts that meet your precise functional and aesthetic specifications, streamlining your supply chain and ensuring unparalleled quality control.

The Integrated Workshop: Mastering Multi-Process Fabrication

The true strength of our service lies in our coordinated one-stop processing capabilities. We understand that a complex aluminum fabrication part often requires more than a single operation. Our facility is equipped to seamlessly sequence CNC milling for primary shaping, precision turning for rotational features, EDM wire cutting for intricate internal geometries or hard materials, and skilled grinding for supreme surface flatness. This unified approach under one roof is transformative. It eliminates the delays, quality variances, and added costs of coordinating multiple vendors. More critically, it allows our engineers to design a cohesive manufacturing strategy from the start, ensuring that every stage is optimized for the next. This results in faster lead times, consistent quality, and a single point of accountability for your entire project, making us a reliable partner for custom CNC machining projects of all scales.

The synergy between different processes is key. For instance, a part might first be roughed out on a CNC milling center, have its internal contours finished via precision EDM, and finally have its mounting faces ground to a perfect finish. By controlling this entire workflow, we manage thermal effects, material stresses, and fixture references in a way that disparate shops cannot. This deep integration is what defines our approach to manufacturing aluminum fabrication parts and ensures that complexity is managed efficiently.

Material Intelligence: Selecting the Right Aluminum Alloy

The performance of any custom aluminum part begins with the material itself. Aluminum is not a single entity but a family of alloys, each with distinct properties. Our experience guides clients in selecting the optimal alloy for their specific application. For high-strength structural components, we often recommend 6061 or 7075 alloys. When superior thermal conductivity or fluidity for thin walls is needed, alloys like 5052 or specific casting grades may be preferable. For applications demanding excellent anodizing results, we guide the selection towards alloys known for producing uniform, aesthetic finishes. This consultative material selection process ensures that the foundation of your aluminum fabrication part is perfectly aligned with its end-use requirements, preventing issues related to corrosion, wear, or mechanical failure down the line.

Engineering Precision into Every Micron: Our Tolerance Guarantee

Achieving a tight tolerance like ±0.01mm on a complex, multi-process part is a testament to rigorous process control. This precision is non-negotiable for components destined for aerospace assemblies, medical devices, or high-performance automation. Our commitment begins with high-stability CNC machines and is enforced through a culture of meticulousness. We employ advanced testing equipment such as Coordinate Measuring Machines (CMM) not just for final inspection, but for in-process verification at critical manufacturing stages. This proactive measurement ensures that any potential deviation is corrected immediately, long before the part is completed.

Maintaining such precision across a multi-step fabrication process requires environmental and procedural discipline. Our workshop maintains stable temperature controls to minimize thermal expansion effects on both machines and materials. Tooling is meticulously managed, with wear monitored and compensated for automatically or through scheduled changes. Every single custom aluminum part undergoes a 100% QC quality inspection before delivery, and we provide the corresponding inspection report for your records. This end-to-end control system, from the first cut to the final measurement, is how we guarantee that our aluminum fabrication parts consistently meet the demanding specifications required by global industries.

The Final Touch: Strategic Surface Treatment Customization

The journey of a premium component doesn’t end at machining. The right surface treatment enhances performance, durability, and brand identity. We offer a complete in-house portfolio—from protective anodizing and rugged powder coating to decorative polishing and high-tech PVD coatings. Our value goes beyond offering a list; we provide strategic consulting. Our technicians will recommend the ideal finish based on your part’s application: whether it needs corrosion resistance for marine environments, electrical insulation, enhanced wear resistance, or a specific color and texture for consumer-facing products.

For example, hard anodizing (Type III) can add a ceramic-like layer to aluminum fabrication parts, drastically increasing surface hardness and wear resistance for moving components. Clear anodizing (Type II) provides corrosion protection while maintaining the metallic look. Powder coating offers a vast range of colors and textures with excellent impact resistance. PVD coatings can apply thin, ultra-hard layers of materials like titanium nitride for both decorative gold tones and functional protection. This depth of in-house expertise in customized surface treatment ensures your custom aluminum parts are not only dimensionally precise but also perfectly finished to survive and excel in their intended environment.

Why Partner with Us for Your Fabrication Needs?

Choosing Shenzhen Huarui Century Technology means selecting a partner built for manufacturing success.

A Decade of Cross-Industry Expertise:

Our ten years of experience in providing OEM and ODM services have given us deep insight into the fabrication challenges across sectors, from industrial machinery to electronics. We’ve solved problems related to vibration damping in frames, heat dissipation in enclosures, and weight optimization in moving parts. This accumulated knowledge is applied to every new project, helping to foresee and mitigate potential issues before they arise.

The One-Stop Advantage:

By consolidating design, machining, finishing, and inspection, we simplify your procurement, reduce logistical overhead, and accelerate your time-to-market significantly. You avoid the headaches of managing multiple suppliers, aligning different quality standards, and dealing with delayed hand-offs. We become your single point of contact and responsibility.

Built on a Foundation of Quality:

Our ISO-certified operations and commitment to a 99.99% product qualification rate demonstrate a systematic approach to quality that you can rely on for both prototypes and production volumes. This isn’t just a claim; it’s a result of documented procedures, trained personnel, and a culture where quality is everyone’s responsibility.

Collaborative and Responsive Service:

We believe in partnership. From rapid online quotations and design for manufacturability (DFM) feedback to transparent communication throughout production, we ensure a smooth and responsive collaboration. Our goal is to make the process of ordering custom aluminum parts as straightforward and predictable as possible.

Applications of Precision Aluminum Fabrication

Our comprehensive service is ideal for manufacturing complex enclosures, structural frames, brackets, and integrated assemblies. We produce robust chassis for robotics and automation, where parts must be light yet rigid, with precisely located mounting points for sensors and drives. We manufacture precisely toleranced housings for communication equipment, where EMI/RFI shielding and heat dissipation are critical. For the automotive and aerospace sectors, we create finely finished components and prototypes where weight savings and strength are paramount. In the medical field, we fabricate parts that meet stringent requirements for cleanability and biocompatibility. By handling all fabrication steps, we are uniquely positioned to support projects where the custom aluminum part is a critical, multifunctional element of a larger system. Our ability to deliver a complete, finished component accelerates your assembly process and reduces total integration time.

Begin Your Streamlined Fabrication Project

Initiating a project is straightforward. Share your CAD drawings with our engineering team. We will provide a prompt, comprehensive quote that encompasses all necessary processes, from initial material selection to final surface treatment. After approval, we move into our integrated production flow, keeping you updated at every milestone until your finished, high-quality aluminum fabrication parts are delivered. We support projects of all volumes, from single prototypes to large production runs, with the same attention to detail and quality. Contact us today to experience the efficiency, reliability, and peace of mind that comes with partnering with a true one-stop manufacturing specialist. Let us show you how our expertise in custom aluminum machining and fabrication can bring your most challenging designs to life.