CNC machining factories are an essential part of many production based industries. Using the latest technology, these factories do precise cutting and shaping. Investing In Automation: One effective approach for CNC machining factories like Huarui, to improve the efficiency of production is investing in automation. Robots are often used and computer programs control the equipment, allowing it to perform tasks more quickly and precisely. This decreases the length of time needed for part production and also cuts down on errors. What’s more, by following lean manufacturing principles, you can make your business operations even more efficient and reduce waste. CNC machining factories, by streamlining these cnc machining parts processes, can increase productivity and get products to customers quicker.

For CNC processing factory like Huarui, they can improve production efficiency through technology and new equipment by streamlining processes. One approach to do this is through investment in state-of-the-art equipment that can multitask. For instance, multi-axis CNC machines can perform cutting, drilling, and forming of materials in one step which decreases reliance on manual labor – screwing up the process time. Furthermore, using a model-based approach can also help identify bottlenecks and schedule activity to achieve higher output. CNC machining factories can optimize and make decisions on manufacturing an event of to improve efficiency or satisfy customer's demand through analyzing production data.

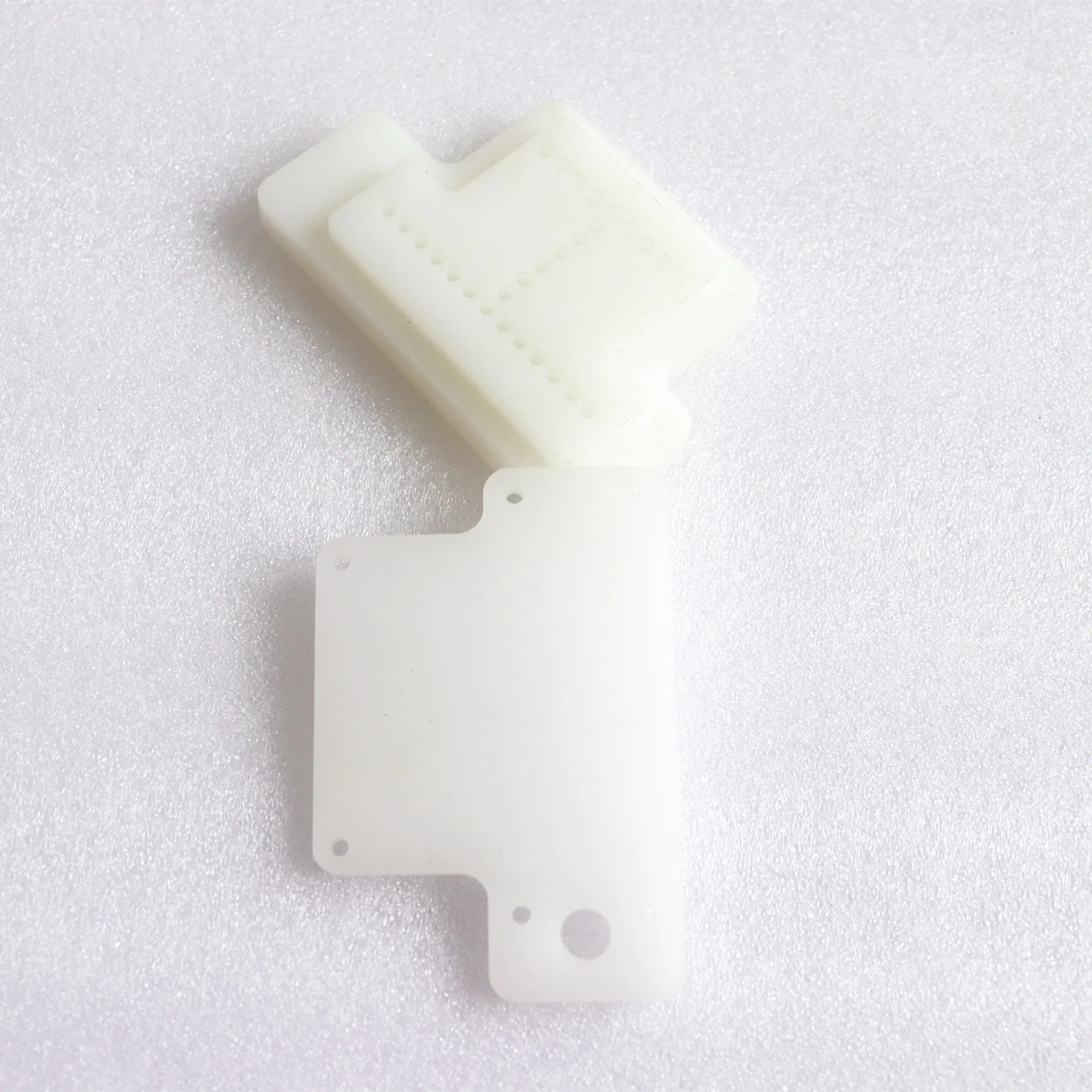

Huarui provides CNC contract manufacturing services to the automotive, aerospace, medical and electronics industries. CNC machining factories can serve individual industrial needs by offering tailor-made parts and components. Automotive may demand high precision power train, chassis components and transmission composed parts while Medical industry on other hand will like to go for complex sorts of implantable and surgical instruments related products. And through close cooperation with all the clients to know what they need, Metal cnc machining factories could provide parts that qualified industry standard and rules. What's more, with a continuously enriched materials and finish types, Huarui could provide the most flexible alternatives to meet different demands from various industries.

We're proud to say that at Huarui, quality control in our CNC machining factory is no joking matter. We take several steps to ensure our products are of the highest quality. More Incredibly, we have professional quality control team in our factory. That means its not happening with customer can't receiving a worse item from here. Firstly, please do not worry about received products quality problem. our QC department will checking each product's quality & appearance before shipping my friend! This is really important for making sure we catch issues early and can fix them before the final product is completely done. Also, we are equipped with advanced machines and equipment which make up for precision manual machining. Also adhere to strict policies and specifications as per consistent uniformity of products. On the whole, our quality control processes ensure us to give out finest goods.

The benefit to partnering with Huarui (a quality CNC machining factory) is that our wholesale prices can accommodate no matter what your budget. Our customers are finding substantial cost savings to their machining job shop's needs by purchasing in volume from us. Our pricing structure is very competitive for high volume orders, which enables organizations to outsource their machining needs to us Economically. Our wholesale prices have been put together to give you value for money and yet not compromise on the high quality of our products and services. With services such as these, Huarui 5 axis cnc machining also becomes an attractive option for any business wishing to streamline production efforts and minimize overhead expenses.

The main merchandise of company try precision Cnc machining factory machined castings, bits of sheet plus metal metal processing. Offer one-stop solutions and ODM solutions OQ 1 sample, and that can be stated in two days. Additionally they supply a free 3D design for customers. The factory now offers an unlimited lifetime on every mold.

The organization has decade of OEM experiences, has a full production and QC system, and now have actually Cnc machining factory custom-designed steel parts for diverse fields like electronic parts, furniture parts, automobile parts, medical parts, etc... In choice, it will probably it ensure that the efficiency and accuracy of this manufacturing process and making CNC processing casting parts, parts as well as sheet steel processing that can meet or exceed customer expectations.

The company offers variety of delivery methods its clients, including express, air, land and sea transportation. Cnc machining factory is shipped to customers North America, South America, Europe, Middle East, Asia, Africa and many other countries regions.

The company obtained IS 09 00 1 as well has received a lot of praise its Cnc machining factory to quality control customer service.