Your business can get revolutionized with a new range of custom product and the novel concept of producing bespoke goods. With this service you are able to get fast prototyping done at low cost before starting full production. This might come in handy for testing out new ideas, making adjustments and ensuring your final product fulfils your expectations. Small start ups and large corporations, both have reasons to avail the benefits from CNC prototype service

Speed of prototyping One of the major benefits associated with CNC prototype service is indisputable speed in getting prototypes made. Rapid Prototyping It takes couple of weeks to even month by aluminum sheet metal stamping traditional way of prototyping, but if you are using CNC machine then within a few days you have your prototype ready. It can help you stay ahead of them and get your products to market more quickly.

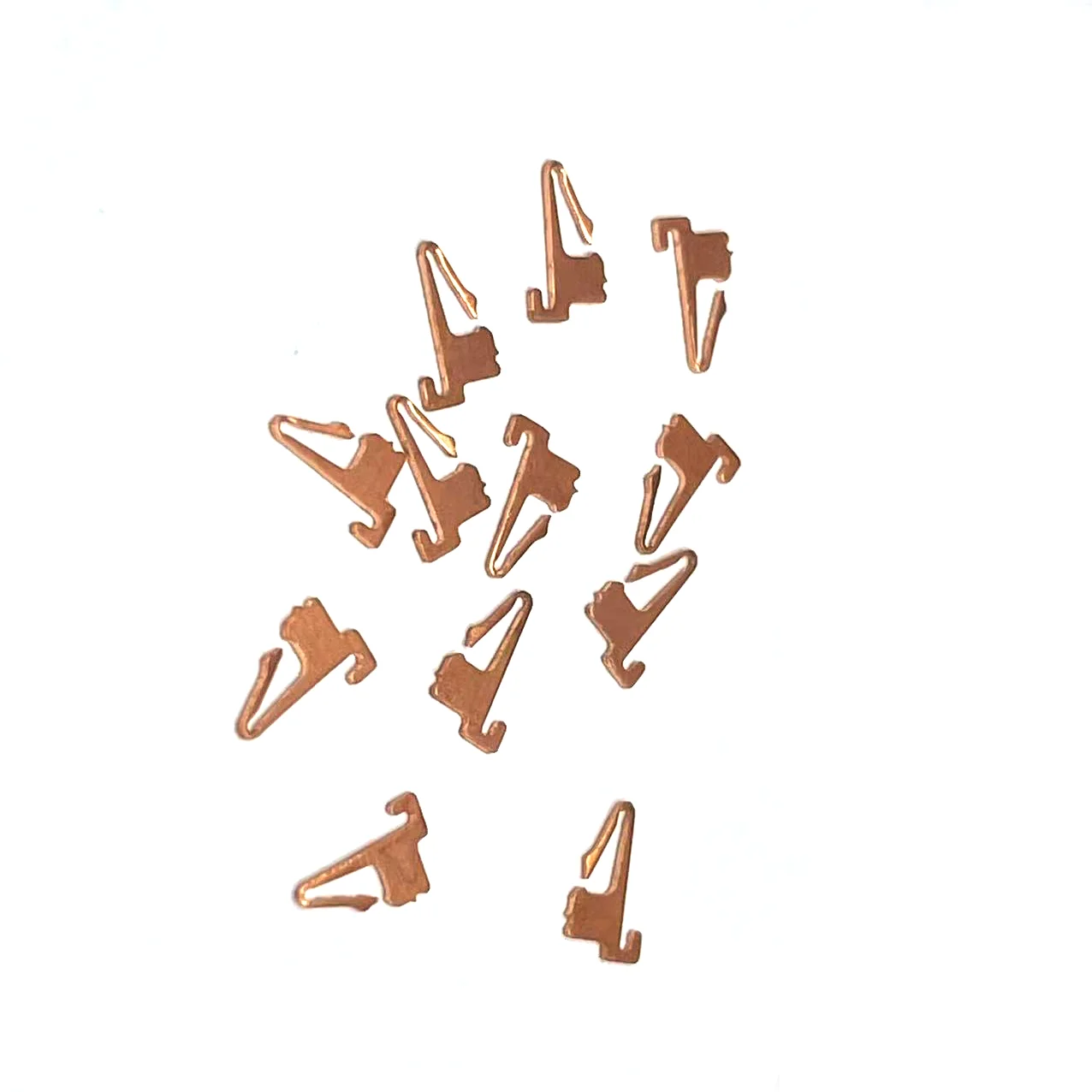

Besides, CNC prototype service also have high precision and accuracy. CNC machines are able to cut complex shapes and provide high precision, that guarantees your prototype is the same as final product. This level of accuracy can facilitate your ability in finding any design flaws so you can adjust accordingly before going into large scale production. Using CNC prototype service has another benefit that these parts are cost-effective. Using a CNC machine to build prototypes, you can save a lot of expensive cost for tooling and custom cnc cutting molding. This is a useful aspect that can save you money in the long term and get you into a market with an accumulated potential.

When you are searching for the best CNC prototype companies, there are some important considerations to make. The first, and most important consideration is to use a company that has experience working will all types of industries and materials. This experience can guarantee your prototypes are of the highest investment casting parts quality and what you asked for.

CNC prototype service is essential at the design and product development stage of businesses, as it enables companies to produce actual prototypes of designs in a relatively quick and cost efficient process. Such prototypes are useful for testing, validating and improving a product before it enters mass production. Utilizing CNC machining, businesses can create precision prototypes that are to the exact specification of the final product.

When selecting the CNC prototype service, we need to pay attention to several aspects in order that your prototypes will be good and of great reliability. First of all, you need to find a company who has the relevant industry experience and can demonstrate they produce quality prototypes. Secondly, the potential of the provider including what materials they are able to work with and size/complexities in parts that can be produced. Finally ensure the service has a quick turn-around time and pricing that falls within your project timeline price range.

S0 1 0 1 certificates, all Cnc prototype service be inspected and demonstrated customers via video prior shipment ensure high quality. It has received a lot of praise for its dedication quality control and customer service.

Year the providers includes a 10- Cnc prototype service experience. Moreover it has a full production quality control line. OEM customized metals parts are accessible in most furniture areas various auto parts, electronic parts, medical products etc. Maybe not only can it be equipped to ensure precision plus efficiency, but create CNC casting processing additionally, casting and sheet-metal processing that exceed the requirements associated with the customer.

The main merchandise of company try precision Cnc prototype service machined castings, bits of sheet plus metal metal processing. Offer one-stop solutions and ODM solutions OQ 1 sample, and that can be stated in two days. Additionally they supply a free 3D design for customers. The factory now offers an unlimited lifetime on every mold.

The company offers variety of delivery Cnc prototype service its customers, including air, express, land sea transport. The company exports its products North America, South America Europe, Asia, Africa, Middle East other countries.