One of the major benefits of titanium CNC machining is that it can hold up to very heavy repetitive use. Titanium is a very strong and yet lightweight material so it is used in applications where a high strength to weight ratio is necessary. This makes it a favored material in industries like aerospace, medical and automotive

Not only is titanium strong, it is also corrosion resilient which makes it ideal in environments where chemicals and moisture are an issue. This resistance to corrosion means the aluminum cast parts titanium parts and components remain intact and last longer, which means they don't need to be replaced or maintained as frequently.

Also, titanium is biocompatible and can be used safely in medical implants and devices. Its biocompatibility, meaning its potential to interact with the human body without negative implications, makes it an attractive material used within medical applications as orthopedic implants or dental and surgical instruments

Our staff of specialists is committed to delivering excellent customer service by demonstrating the highest level of technical skill. From concept through large volume production, we have the expertise and systems to meet your most demanding cnc precision machining service requirements.

With our high end titanium CNC machining, we are always trying to provide higher quality titanium product with lower cost and super services. Whether you need highly accurate parts for the aerospace sector, custom titanium machining for medical equipment manufacturers or heavy duty machining services for all other cnc precision machining parts industries, Huarui is the company to turn to.

Wholesale Titanium CNC Machining Huarui provides wholesale titanium prototype machining for businesses that want to manufacture high-quality titanium parts and products. Titanium Titanium is a strong, lightweight metal commonly used in aircraft, automobiles and medical devices. CNC machining is an efficient and highly accurate method for manufacturing metal parts by cutting material using computer controlled machines based on a 3D design. Huarui provides wholesale titanium CNC machining services, allowing businesses to enjoy cost-effective production, quick lead times and superior quality components. Whether you are looking for customized titanium parts or mass production components, Huarui can provide the skills and equipment to make your project a success.

For accurate titanium CNC machining services you can trust, Huarui will be your best option. Huarui has many years experience in this line and have a groups of welding experts who specialize in titanium. They also use a range of modern CNC machines and tools to deliver precision and perfection always. When you place an order with us for custom turn-milled parts, you can be certain that your components will meet every requirement for the perfect performance. No matter if you need a small aluminium casting parts prototype order, or hundreds of high volume production runs, Huarui has the ability and technology to perform both with excellence.

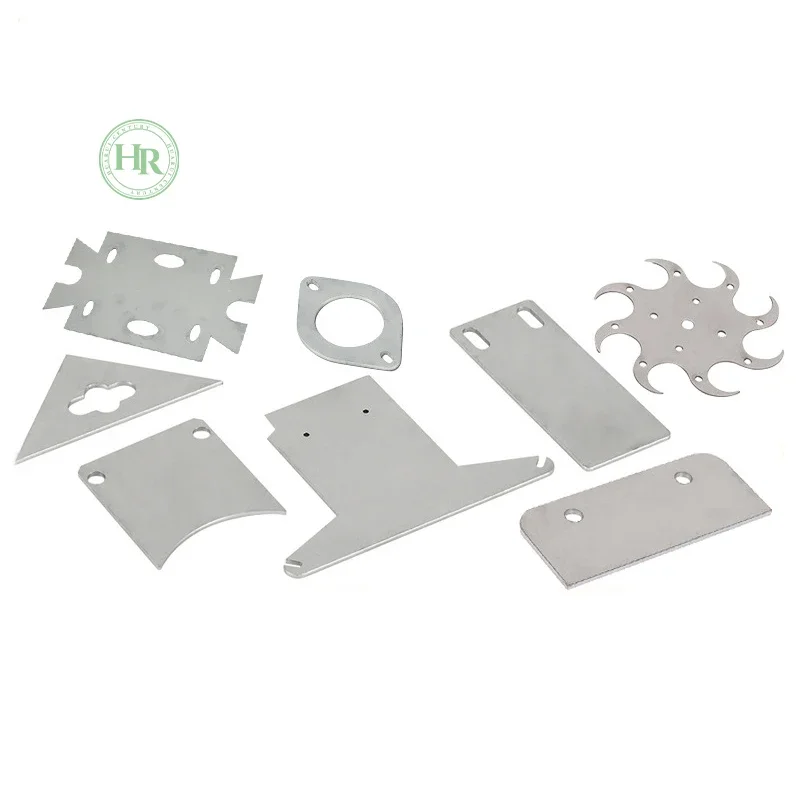

The greatest products connected with ongoing company include precision Titanium cnc machining casts, machined parts and sheet metal processing. We offer OEM along with ODM solutions, OQ for 1 piece, and samples are made within 2 days, and customers can design their very own 3D designs. The factory also provides the customer a full life free time on all molds.

In order allow clients to get goods Titanium cnc machining and quickly company offers sea transportation, land transportation, express delivery, air transport. The company exports products North America, South America Europe, Asia, Africa, Middle East other countries.

The company acquired IS 09 00 1 as well as the company been Titanium cnc machining widely for its dedication to quality control customer service.

The organization has over 10 years of many years of OEM experience. It also has a manufacturing that was quality control complete line. Titanium cnc machining customized metals parts can be found in a range of categories like furniture, auto components, electronic components, medical equipment etc. In addition, it is able to ensure accuracy and efficiency, but make CNC processing casting parts, casting elements along with sheet metal processing that meet or surpass the expectations of the client.